In the case of the Holbo mk2 turntable, the air bearing is only in the vertical plane. Even a 5 kg platter works and plays very well. The height of the air gap and the medium in the sliding bearing greatly affect the sound and the final result. You can choose from a huge number of materials for its manufacture, because there are no large loads in the radial direction. The medium in the sliding bearing of the Holbo mk2 tt is neither oil nor grease. It greatly affects the sound.About the airbearing for the platter, may I ask whether it is airbearing for both the vertical and horizontal / radial planes, or only for the vertical plane like the Micro Seiki / TechDas ? Thanks

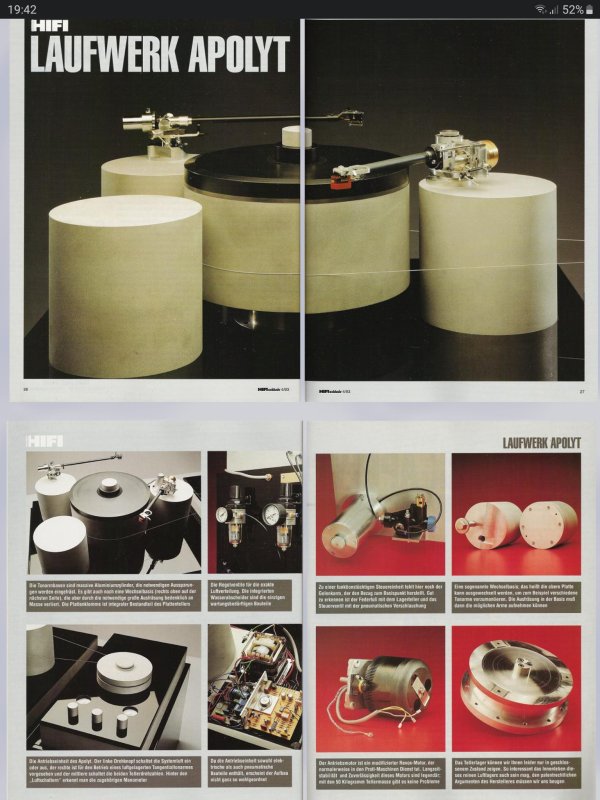

To make it clear what I'm talking about, below is a picture of a real air bearing, which I made more than 30 years ago. Of course, it has its advantages, but the cost of manufacturing and the weight of the platter it carries are enormous and I can't calculate it for a normal price of a turntable. A real air bearing requires a platter that weighs at least 50 kg for correct sound.