I emailed Dino Lite some time ago and here is their response...

“Thank you for contacting Dino-Lite microscopes with your request for information. For your reference here is an example of a customer using our Dino-Lite for your application:

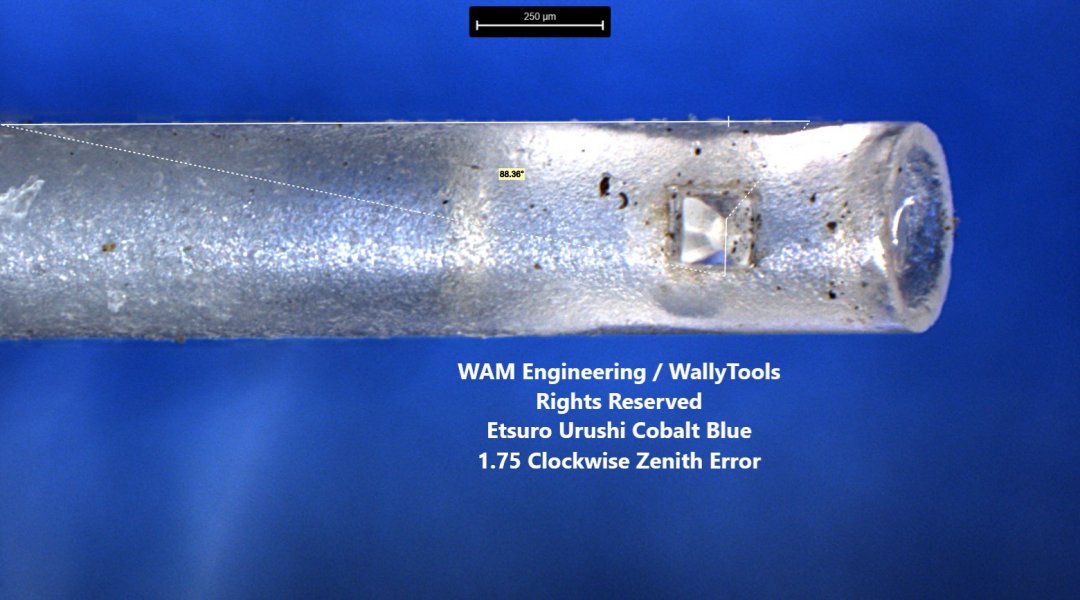

How to Use a USB Digital Microscope to set 92 Degree Stylus Rake Angle (SRA)

In the example above, the customer removed the plastic cap of our microscope to achieve the working distance they desired, we do not advocate this practice as it is destructive to the device and voids your hardware warranty. We recommend a microscope with a specialized removable cap that will allow you to focus at high magnifications from further away. I'll include both the original microscope and our recommendations below:

AM3113 -

https://www.dinolite.us/products/am3113($249.00) (Original microscope, warranty voided if modified)

AD4113T -

https://www.dinolite.us/products/ad4113t($449.00) (Our recommendation)

You will typically need to secure the microscope in a stand for viewing at higher magnifications and stability, the article I linked above features a gooseneck stand, these can be unstable and drift somewhat while in use. I'll include a link to that stand and my recommendations below:

MS33W -

https://www.dinolite.us/products/ms33w($49.00) (Original stand from article)

*Recommended Stands*

MS33A -

https://www.dinolite.us/products/ms33a($99.00)

RK-06A -

https://www.dinolite.us/products/rk-06a($189.00)

RK-10A -

https://www.dinolite.us/products/rk-10a($269.00)

The AD4113T will have a working distance of 1cm at 200x magnification and 1.5cm at ~240x magnification (without the cap). The magnification for the article was around ~175 - 200x, working distance was about 1cm.

I would recommend you use the maximum magnification of the AD4113T as it will give you more working distance and a larger FOV to align your needle.”