Starting this thread to discuss Pure Audio Project open baffle speakers, upgrades and tweaks. @Kingrex - if you have had both the horns and Coax10, I would be interested in hearing how they compare. And I copied your earlier post below.

What cables upgrades did you use? And can you share a picture of where you located the crossover? Is it attached to something else, or sitting on the floor? I was wondering about the height of the midrange/tweeter and if I should rake the front up. My system will be the Trio15 Coax10, Playback Designs MPS-8 source and Pass Int-25 amp. I'm still waiting for my walnut baffles to ship from RJ Millworkers.

What cables upgrades did you use? And can you share a picture of where you located the crossover? Is it attached to something else, or sitting on the floor? I was wondering about the height of the midrange/tweeter and if I should rake the front up. My system will be the Trio15 Coax10, Playback Designs MPS-8 source and Pass Int-25 amp. I'm still waiting for my walnut baffles to ship from RJ Millworkers.

You have to get the updated speaker cables. Its critical.

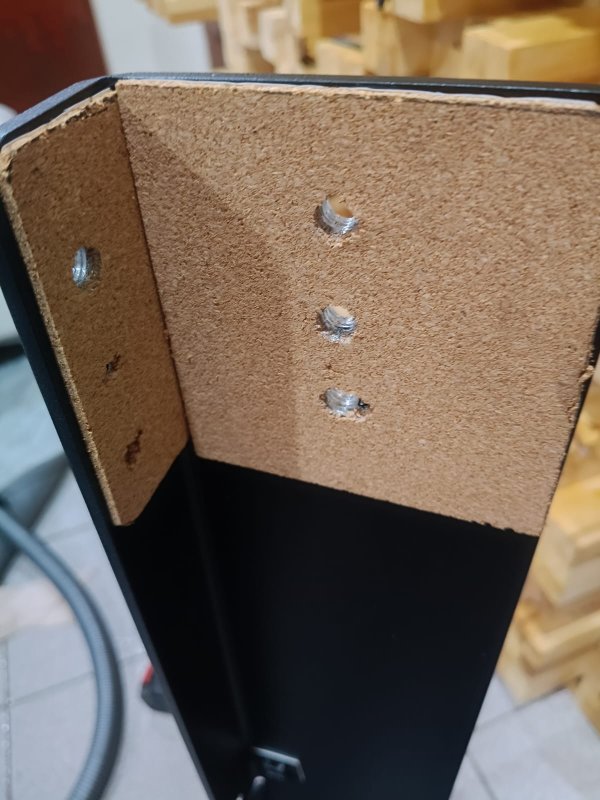

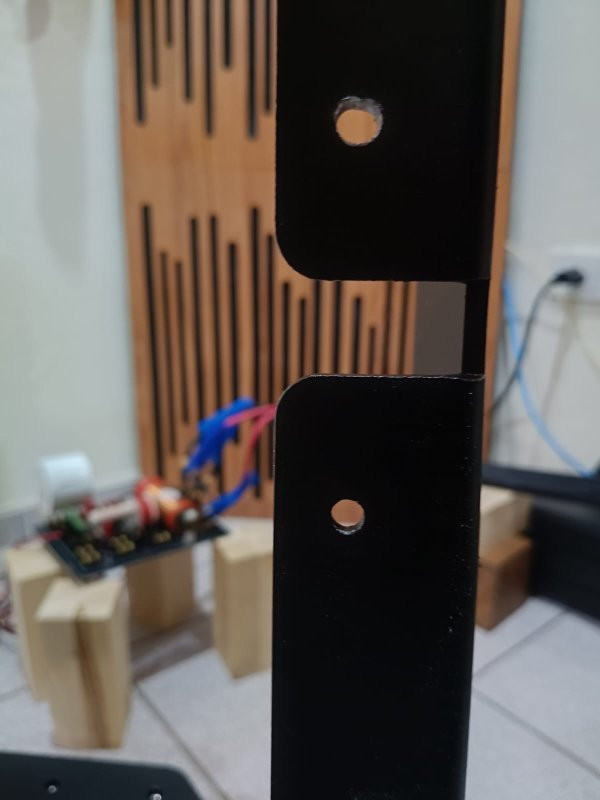

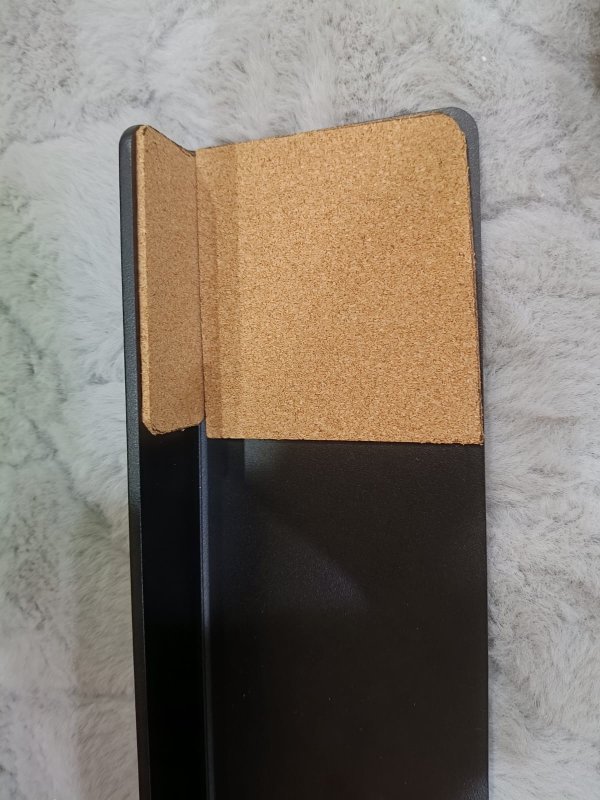

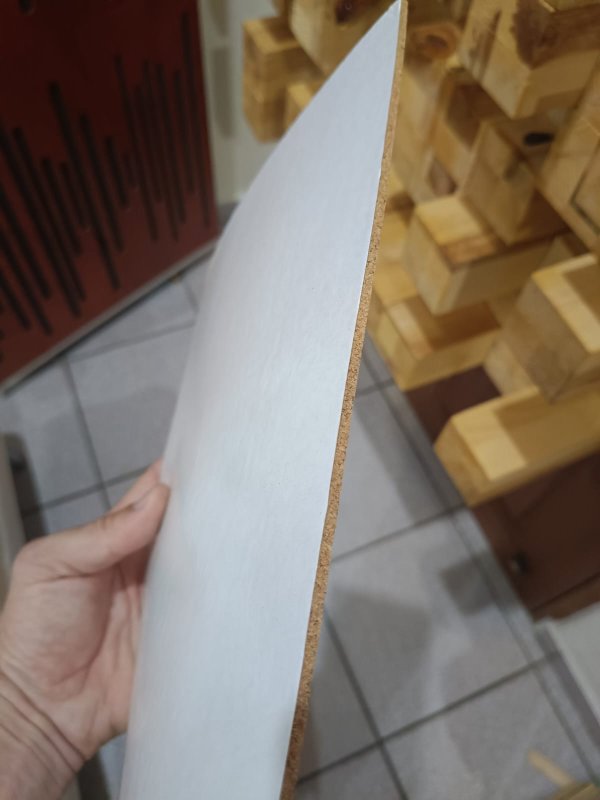

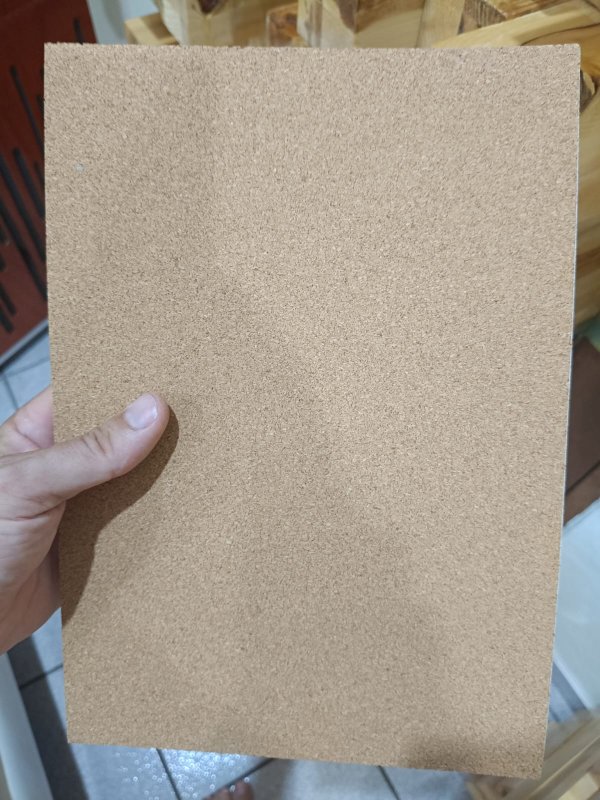

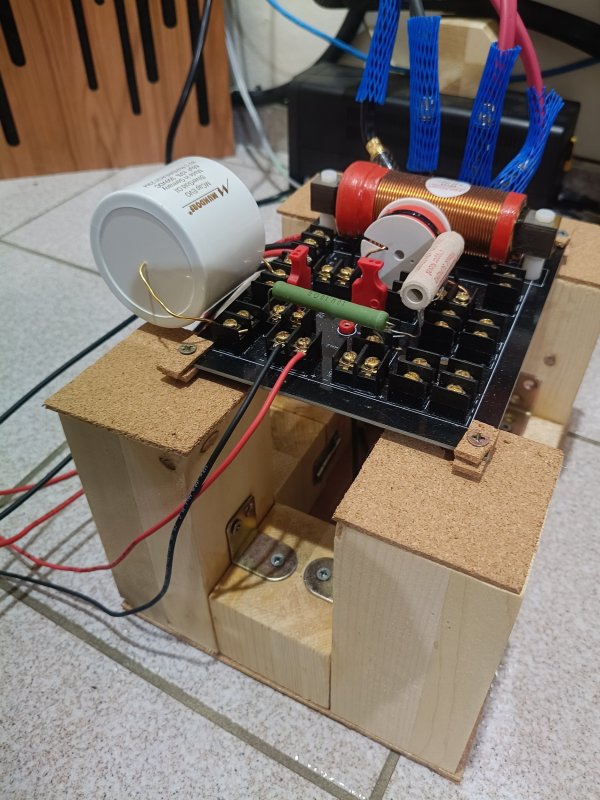

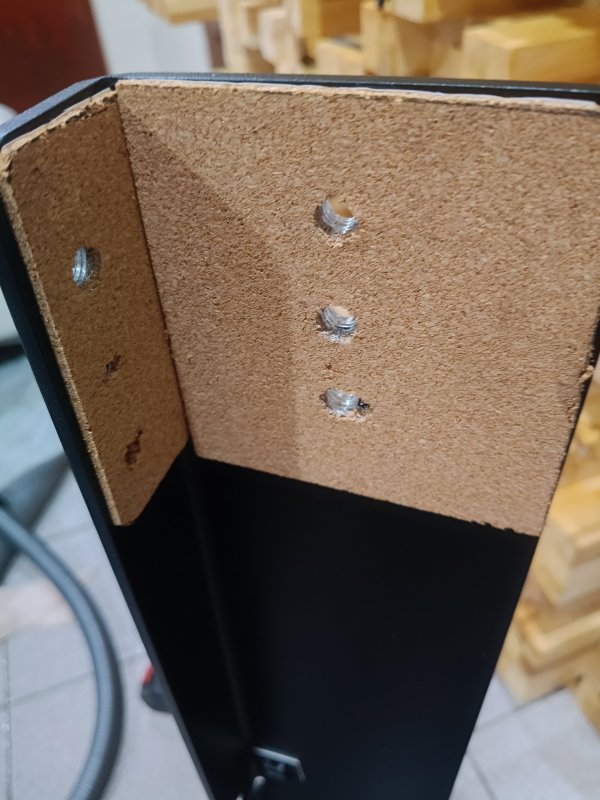

And , you have to separate the crossover from the frame. Again critical.

If the crossover is touching the frame, the music is very smeared from the intense physical vibration.

If you use stock, instead of upgraded cables, you loose life, air and bass. Less coherent.

The speaker is very good with these tweeks. You don't need to futz with any caps or reaistors with the Coax crossover.

You need to be patient. They take 500 hours like any speaker to break in. 2000 or a year to really be there. I actually put my coax in the basement connected to a class D amp and laptop for week and let it rip sitting on the floor. I would go dowm 3 or 4 times a day to switxh the album and volume.

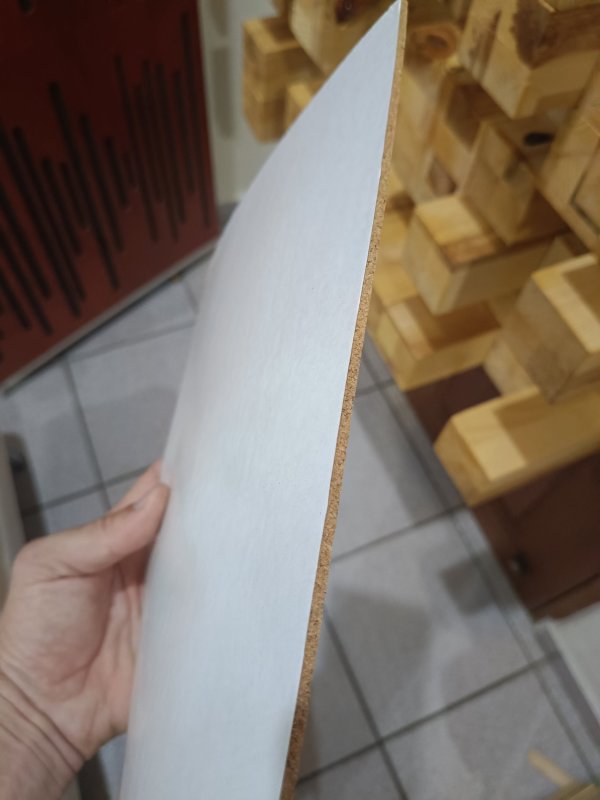

Also, mine sit on a 9 inch tall very heavy block of wood that sits on fiberglass insulation. A rug would also work. Massive improvement in bass. Just shocking. And, it raises the center of the coax much closer to ear height. Otherwise its too low and like sitting in a balcony.

The fabric over the top keeps the sun from striking the driver. That is all its for.

Last edited by a moderator: