Thanks .. the 1/4 wavelength cancelation is pretty reliableIt was my previous room - I am not sure of the exact distance, but yes something like 2,2m. I put the speakers at such distance because the room was symmetrically wider at such location.

My dedicated audio room build - QuadDiffusor's Big Dig

- Thread starter QuadDiffuser

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thanks .. the 1/4 wavelength cancelation is pretty reliableI wondered if it was wall behind speakers.... obviously a nice size room !

My previous room had two feet stone solid walls - it was predictable and measurements fully agreed with simulators and calculators.

My current new one is vaulted and 20x30 feet, but mostly double drywall - a real nightmare to understand and control. It will need time ...

Yes .. give me solid walls every time!My previous room had two feet stone solid walls - it was predictable and measurements fully agreed with simulators and calculators.

My current new one is vaulted and 20x30 feet, but mostly double drywall - a real nightmare to understand and control. It will need time ...

Still its a good size

After further examinations and deliberations, these two prototype 1.5mm and 3.0mm steel plates will be modified in the following manner:

1) steel on the horizontal sections (both top and bottom) - keeping only what's essential for the resilient mounting brackets (about 20%), and removing the rest (about 80%) for freer vibrational movement

2) mounting bracket - to be shortened, eliminating the air gap

3) abundant application of 3M spray glue, to bond Basotech foam directly to the underside of the steel plates

4) direct contact between the Basotech foam and the gypsum wall

5) for vertically mounted units, potentially use only one mounting bracket on top (instead of two) to maximize vibrational freedom

The steel plate of VPR is not suitable for bending or serving as a supporting bone, which will prevent the free vibration of the steel plate, because its low-frequency absorption requires the free vibration of the plate to couple and absorb.

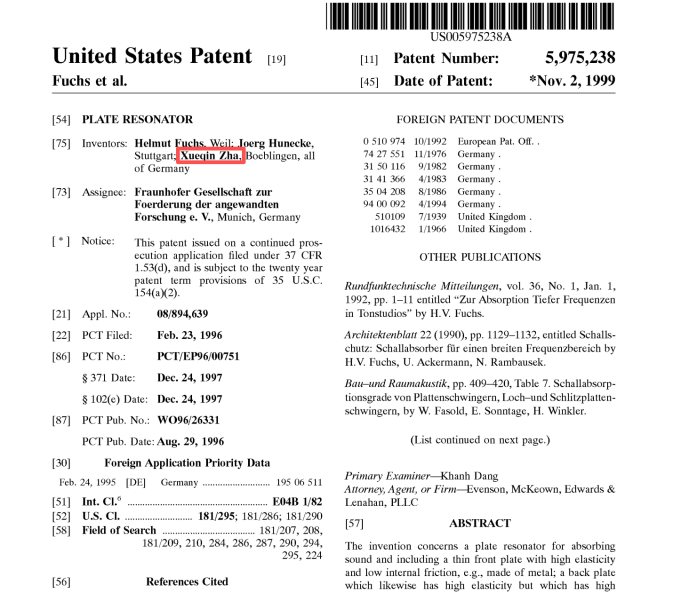

VPR is now have manufactured in China, as some of the VPR patents are owned by Dr. Cha Xueqin of China. There are some authorized manufacturer. They generally target anechoic chamber projects and are less focused on private hifi rooms.

The price of Chinese-made VPRs is significantly cheaper than RPGs.

I've purchased them for some clients. However, they don't have a wide selection of sizes.

Crap. Similar to my room. Vaulted with about 16 x 22 feet. I have a bass boom at some unknown frequency. I need to figure it out. Sometimes it plays perfect. Then just the right song comes on and you hear it.My previous room had two feet stone solid walls - it was predictable and measurements fully agreed with simulators and calculators.

My current new one is vaulted and 20x30 feet, but mostly double drywall - a real nightmare to understand and control. It will need time ...

Crap. Similar to my room. Vaulted with about 16 x 22 feet. I have a bass boom at some unknown frequency. I need to figure it out. Sometimes it plays perfect. Then just the right song comes on and you hear it.

I am happier than you. No bass boom at all, my problem is a bass dip due to cancellation. I suggest you get the REW software and a calibrated microphone. Do not rely on smartphone apps!

...if you can identify the frequency, these GIK traps are somewhat "tuned" and I think they do custom frequency versions. One can calculate that stuff, and DIY, if you have the math king-fu.

www.gikacoustics.com

www.gikacoustics.com

GIK Acoustics Scopus Tuned Membrane Bass Trap (T70)

The Scopus Tuned Membrane Bass Trap (T70) covers a tuned frequency range around 55 Hz to 100 Hz leaving mid- and high-end intact instead of deadening a room.

Back in the late 20-teens I experimented a lot with this technology. I bought and read his book where he has a couple chapters that talk about the VPR. There used to be several very long forum posts (on other forums) where Dr. Fuchs chimed in on the myriad questions people had. Here are my take aways.After further examinations and deliberations, these two prototype 1.5mm and 3.0mm steel plates will be modified in the following manner:

1) steel on the horizontal sections (both top and bottom) - keeping only what's essential for the resilient mounting brackets (about 20%), and removing the rest (about 80%) for freer vibrational movement

2) mounting bracket - to be shortened, eliminating the air gap

3) abundant application of 3M spray glue, to bond Basotech foam directly to the underside of the steel plates

4) direct contact between the Basotech foam and the gypsum wall

5) for vertically mounted units, potentially use only one mounting bracket on top (instead of two) to maximize vibrational freedom

1. They are simple to make. Harder to make them look nice.

2. the 3M spray glue for foam is very strong. If you try to take/rip the foam off the plate then it will rip foam before the glue line breaks. It is also an elastomeric glue. So the glue line will bend and flex. This is important as we don't want to constrain the movement of the plate. Just damp the movement.

3. I mounted (glued) the foam to a 1/2" piece of MDF and then mounted (glued) the panel to the foam. I then screwed the MDF to the wall. the plate and foam hung there for years without any issues. The steel plate never touched the floor.

6. There are two ways the VPR absorbs energy. One is the vibrational modes of the plate. The other is the basic mass spring mode of plate (mass) mounted to the foam (spring). You can tune each of these by choosing the plate dimensions, the weight of the pate and the stiffness of the foam. It was pretty easy to put the formula into excel and define what you want.

7. I don't encourage using the mass-sping mode. If you want this to go very low in frequency to target one of your lower room modes, you will need a very heavy plate which will make exciting the plate modes more difficult.

8. The real advantage of this technology is that the plate modes are very evenly spread out. So it becomes a broad band absorber that happens to absorb energy from really low frequencies.

9. The type of foam you use really doesn't matter if you just want to use the plate modes. I used a 4" thick polyester acoustic foam. the basotech foam is just a brand of melamine foam. (Just like the magic eraser). One thing you realize is that they are selling the VPR plates commercially, so they have to meet certain fire code ratings. Thus their choice of foam. The only purpose of the foam is to damp the vibrations of the plate.

10. When calculating the X,Y vibrational modes of the plate you see that they depend on the ratio of the modulus of Elasticity to Density of the material. It turns out that this ratio is basically the same for Aluminum and Steel.

11. So I would suggest using aluminum plate. it is much lighter which makes it easier to handle and easier for the acoustic energy to excite the plate.

12. Of course the most important point. You cannot constrain the plate. If you clamp the edges, then that will completely change the vibrational modes of the plate.

If I were to hang these on the ceiling then I would want some kind of safety mechanism. They are heavy.

Good luck.

sbnx,Back in the late 20-teens I experimented a lot with this technology. I bought and read his book where he has a couple chapters that talk about the VPR. There used to be several very long forum posts (on other forums) where Dr. Fuchs chimed in on the myriad questions people had. Here are my take aways.

1. They are simple to make. Harder to make them look nice.

2. the 3M spray glue for foam is very strong. If you try to take/rip the foam off the plate then it will rip foam before the glue line breaks. It is also an elastomeric glue. So the glue line will bend and flex. This is important as we don't want to constrain the movement of the plate. Just damp the movement.

3. I mounted (glued) the foam to a 1/2" piece of MDF and then mounted (glued) the panel to the foam. I then screwed the MDF to the wall. the plate and foam hung there for years without any issues. The steel plate never touched the floor.

6. There are two ways the VPR absorbs energy. One is the vibrational modes of the plate. The other is the basic mass spring mode of plate (mass) mounted to the foam (spring). You can tune each of these by choosing the plate dimensions, the weight of the pate and the stiffness of the foam. It was pretty easy to put the formula into excel and define what you want.

7. I don't encourage using the mass-sping mode. If you want this to go very low in frequency to target one of your lower room modes, you will need a very heavy plate which will make exciting the plate modes more difficult.

8. The real advantage of this technology is that the plate modes are very evenly spread out. So it becomes a broad band absorber that happens to absorb energy from really low frequencies.

9. The type of foam you use really doesn't matter if you just want to use the plate modes. I used a 4" thick polyester acoustic foam. the basotech foam is just a brand of melamine foam. (Just like the magic eraser). One thing you realize is that they are selling the VPR plates commercially, so they have to meet certain fire code ratings. Thus their choice of foam. The only purpose of the foam is to damp the vibrations of the plate.

10. When calculating the X,Y vibrational modes of the plate you see that they depend on the ratio of the modulus of Elasticity to Density of the material. It turns out that this ratio is basically the same for Aluminum and Steel.

11. So I would suggest using aluminum plate. it is much lighter which makes it easier to handle and easier for the acoustic energy to excite the plate.

12. Of course the most important point. You cannot constrain the plate. If you clamp the edges, then that will completely change the vibrational modes of the plate.

If I were to hang these on the ceiling then I would want some kind of safety mechanism. They are heavy.

Good luck.

I really appreciate your post - wonderful advice from experienced hands (and ears), written very clearly. I will most certainly do my best to incorporate them into my VPRs.

Last edited:

Thanks for the thread Quad.

I have learned a lot.

I don't know what you and otbers are doing would be called absorption. Its more keeping the walls of the room from becoming a passive radiator of sorts and adding sound that is not part of the signal. This is beyond absorbing a reflection as I see it.

The process of stopping the walls from vibrating in sympathy is absorbing the primary signal. But it seems quite different than stopping a reflection that is not exciting the wall and creating a new sound wave.

And I accurate on this thought?

I have learned a lot.

I don't know what you and otbers are doing would be called absorption. Its more keeping the walls of the room from becoming a passive radiator of sorts and adding sound that is not part of the signal. This is beyond absorbing a reflection as I see it.

The process of stopping the walls from vibrating in sympathy is absorbing the primary signal. But it seems quite different than stopping a reflection that is not exciting the wall and creating a new sound wave.

And I accurate on this thought?

Hello asdffx, might there be URLs which you can share with me? I'd like to look more deeply in Dr. Cha Xueqin's research documents and products. Googling his name did not result in any meaningful hits. Thank you!The steel plate of VPR is not suitable for bending or serving as a supporting bone, which will prevent the free vibration of the steel plate, because its low-frequency absorption requires the free vibration of the plate to couple and absorb.

VPR is now have manufactured in China, as some of the VPR patents are owned by Dr. Cha Xueqin of China. There are some authorized manufacturer. They generally target anechoic chamber projects and are less focused on private hifi rooms.

The price of Chinese-made VPRs is significantly cheaper than RPGs.

I've purchased them for some clients. However, they don't have a wide selection of sizes.

NoThanks for the thread Quad.

I have learned a lot.

I don't know what you and otbers are doing would be called absorption. Its more keeping the walls of the room from becoming a passive radiator of sorts and adding sound that is not part of the signal. This is beyond absorbing a reflection as I see it.

The process of stopping the walls from vibrating in sympathy is absorbing the primary signal. But it seems quite different than stopping a reflection that is not exciting the wall and creating a new sound wave.

And I accurate on this thought?

Any vibrating thing in the space is absorbing sound energy and turning it into heat. Even QD's qrd diffusers will vibrate and absorb energy so it is quite difficult to predict the end result .. it is normal to have some flexibility in design to fine tune it at the end

Great post !Back in the late 20-teens I experimented a lot with this technology. I bought and read his book where he has a couple chapters that talk about the VPR. There used to be several very long forum posts (on other forums) where Dr. Fuchs chimed in on the myriad questions people had. Here are my take aways.

1. They are simple to make. Harder to make them look nice.

2. the 3M spray glue for foam is very strong. If you try to take/rip the foam off the plate then it will rip foam before the glue line breaks. It is also an elastomeric glue. So the glue line will bend and flex. This is important as we don't want to constrain the movement of the plate. Just damp the movement.

3. I mounted (glued) the foam to a 1/2" piece of MDF and then mounted (glued) the panel to the foam. I then screwed the MDF to the wall. the plate and foam hung there for years without any issues. The steel plate never touched the floor.

6. There are two ways the VPR absorbs energy. One is the vibrational modes of the plate. The other is the basic mass spring mode of plate (mass) mounted to the foam (spring). You can tune each of these by choosing the plate dimensions, the weight of the pate and the stiffness of the foam. It was pretty easy to put the formula into excel and define what you want.

7. I don't encourage using the mass-sping mode. If you want this to go very low in frequency to target one of your lower room modes, you will need a very heavy plate which will make exciting the plate modes more difficult.

8. The real advantage of this technology is that the plate modes are very evenly spread out. So it becomes a broad band absorber that happens to absorb energy from really low frequencies.

9. The type of foam you use really doesn't matter if you just want to use the plate modes. I used a 4" thick polyester acoustic foam. the basotech foam is just a brand of melamine foam. (Just like the magic eraser). One thing you realize is that they are selling the VPR plates commercially, so they have to meet certain fire code ratings. Thus their choice of foam. The only purpose of the foam is to damp the vibrations of the plate.

10. When calculating the X,Y vibrational modes of the plate you see that they depend on the ratio of the modulus of Elasticity to Density of the material. It turns out that this ratio is basically the same for Aluminum and Steel.

11. So I would suggest using aluminum plate. it is much lighter which makes it easier to handle and easier for the acoustic energy to excite the plate.

12. Of course the most important point. You cannot constrain the plate. If you clamp the edges, then that will completely change the vibrational modes of the plate.

If I were to hang these on the ceiling then I would want some kind of safety mechanism. They are heavy.

Good luck.

On ceiling units I have created a box of ply with open face on top , dropped in foam and sat metal plate on top ... the box is then hung from ceiling.. they were concealed in ceiling space but could be built nicely with diffusion or similar on underside if exposed

Part 1 of 3

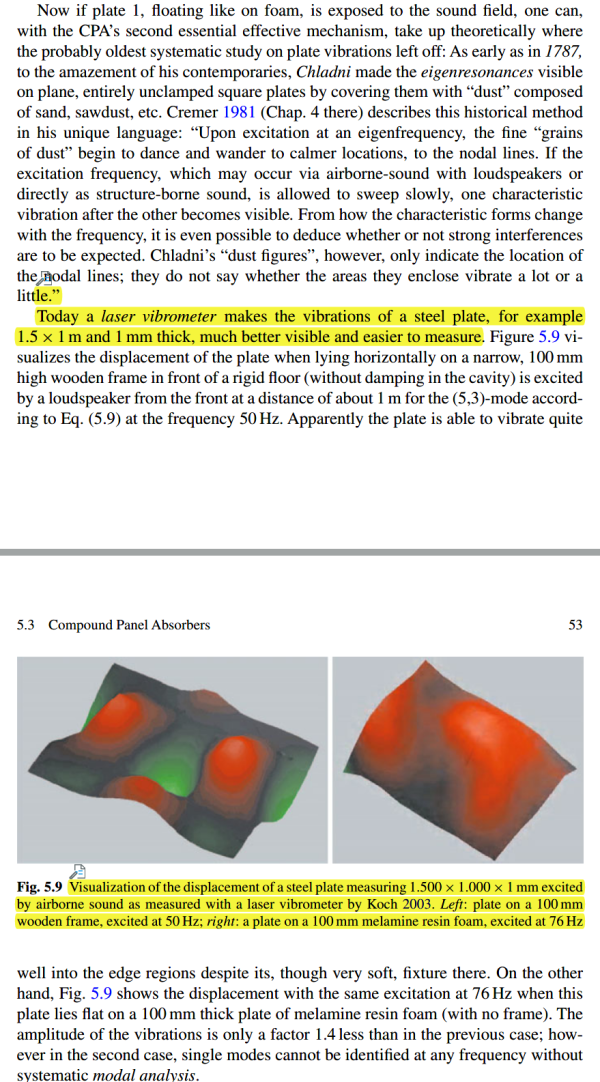

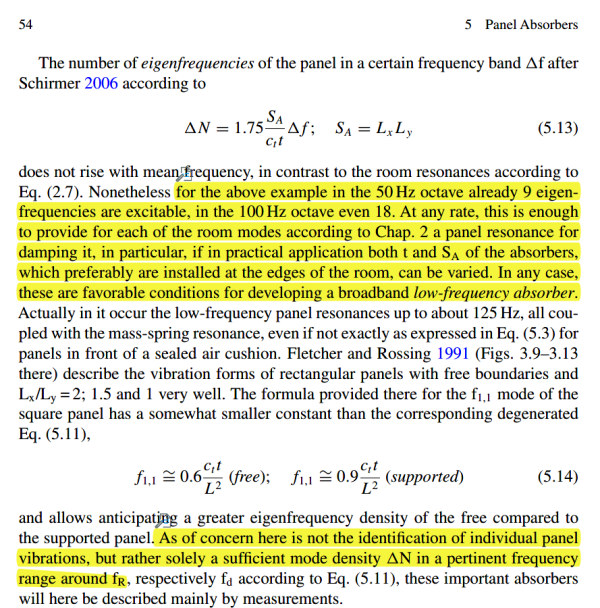

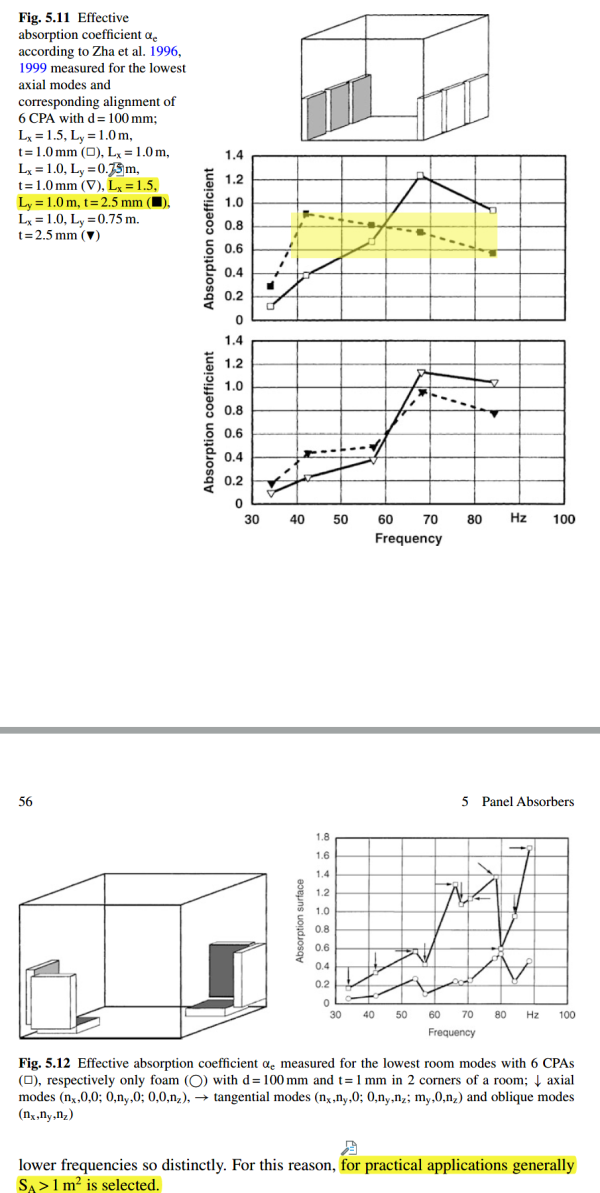

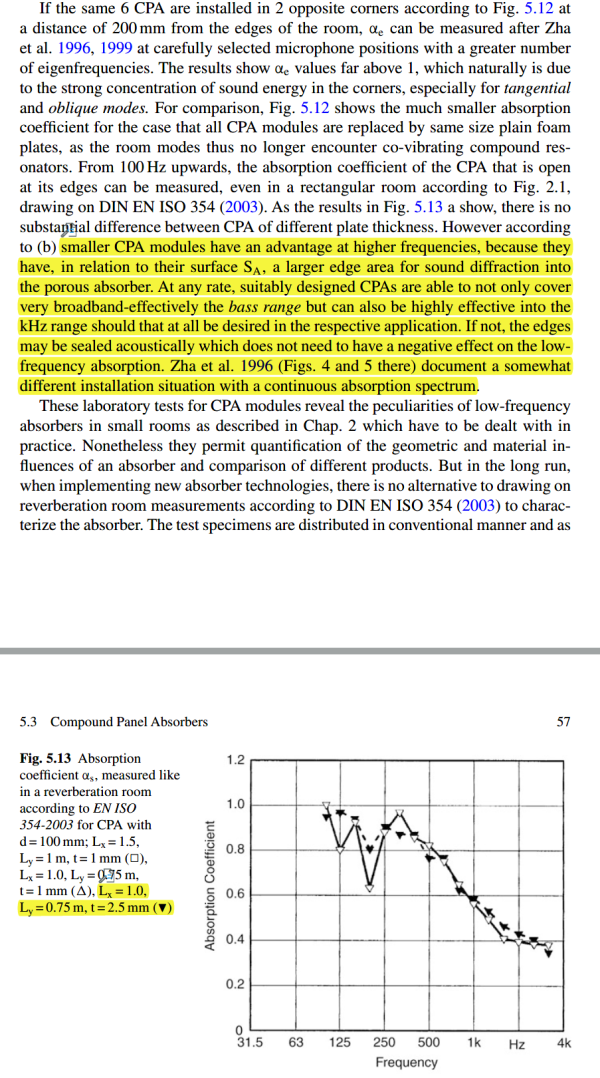

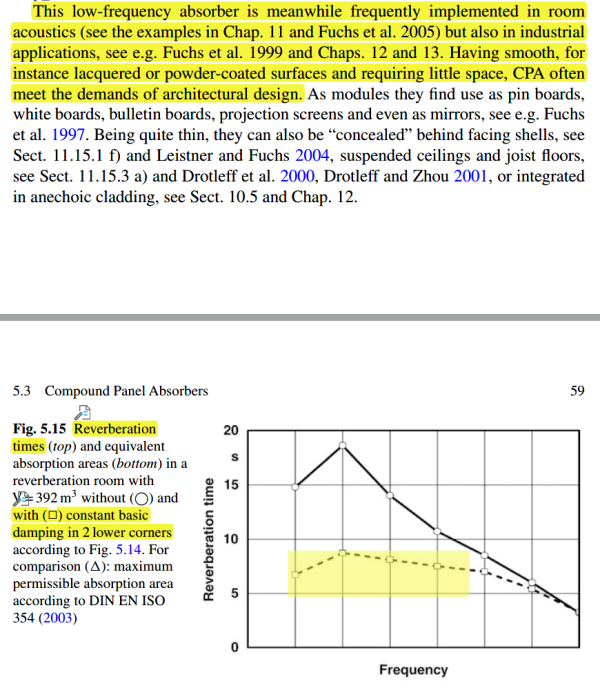

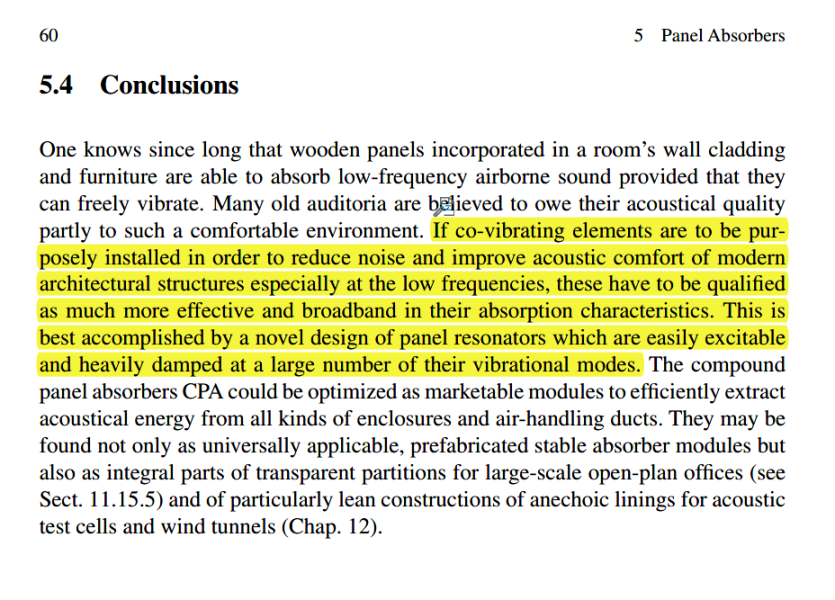

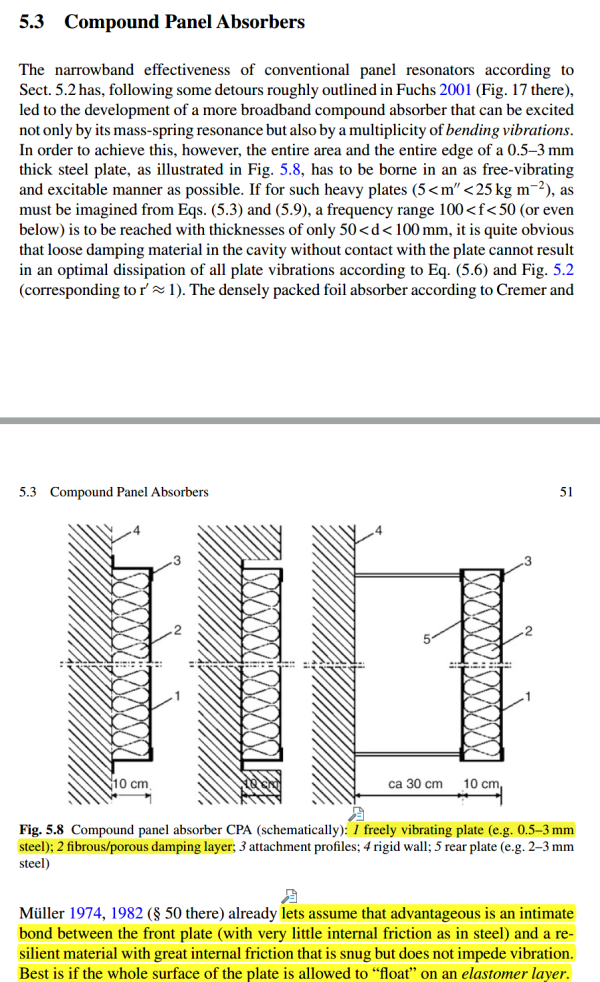

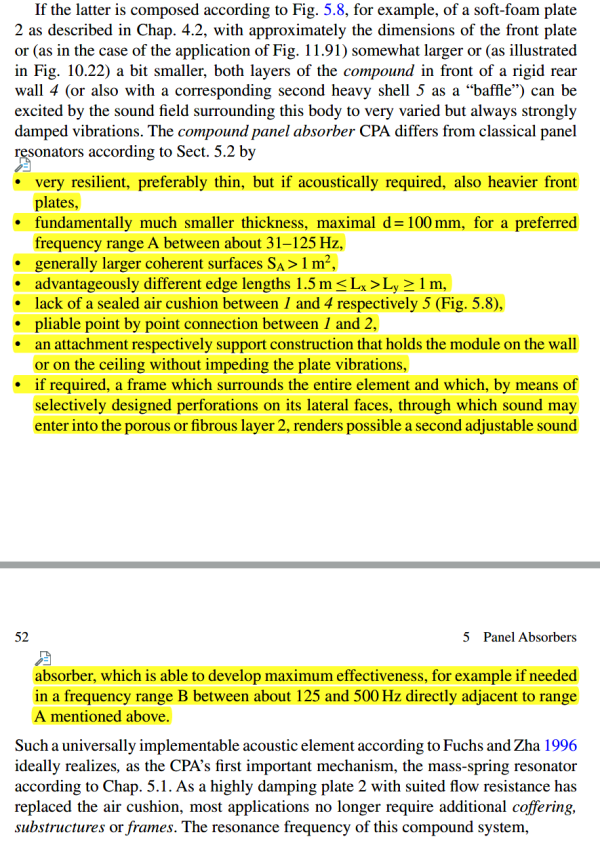

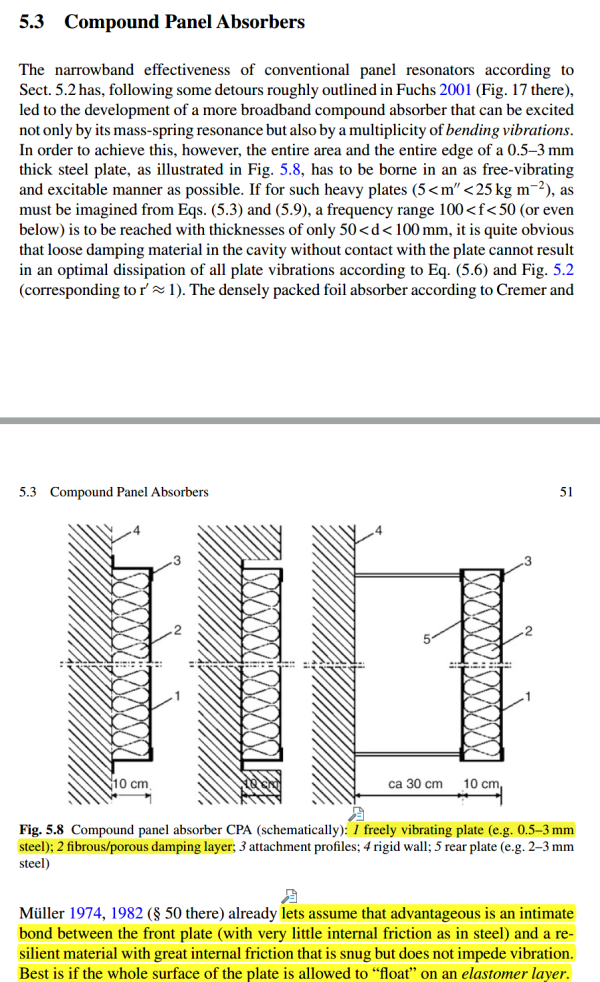

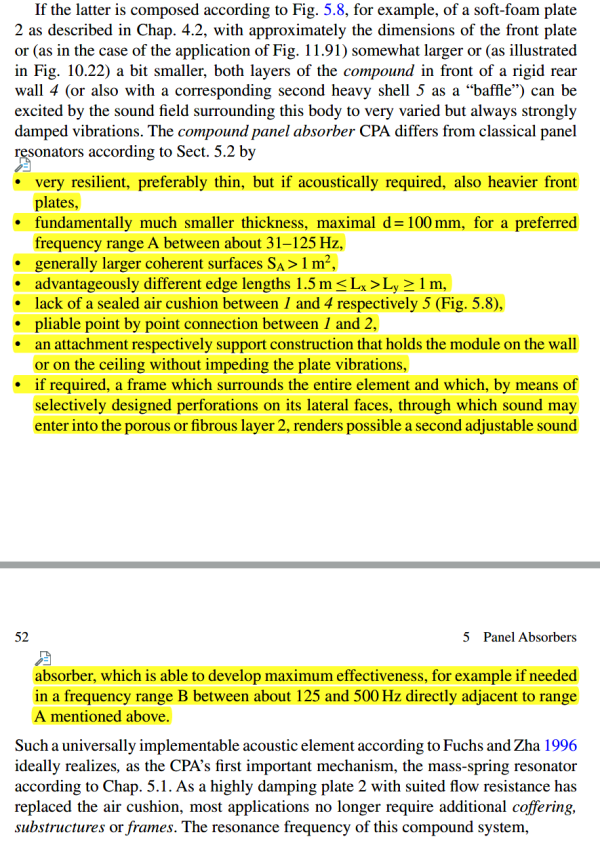

From the eBook, "Applied Acoustics: Concepts, Absorbers, and Silencers for Acoustical Comfort and Noise Control" by Helmut Fuchs, ISBN 978-3-642-29367-2, © Springer-Verlag Berlin Heidelberg 2013. Hopefully reproducing these exerpts won't violate any copyrights... I've highlighted portions I thought were most relevant in yellow.

From the eBook, "Applied Acoustics: Concepts, Absorbers, and Silencers for Acoustical Comfort and Noise Control" by Helmut Fuchs, ISBN 978-3-642-29367-2, © Springer-Verlag Berlin Heidelberg 2013. Hopefully reproducing these exerpts won't violate any copyrights... I've highlighted portions I thought were most relevant in yellow.

Last edited:

I love " it is quite obvious "Part 1 of 3

From the eBook, "Applied Acoustics: Concepts, Absorbers, and Silencers for Acoustical Comfort and Noise Control" by Helmut Fuchs, ISBN 978-3-642-29367-2, © Springer-Verlag Berlin Heidelberg 2013. Hopefully reproducing these exerpts won't violate any copyrights... I've highlighted portions I thought were most relevant in yellow.

View attachment 156529

My simple mind thinks that a metal panel stuck to foam with unfixed perimeter is a narrowish band low fr absorber, the denser the panel the lower the fr .. the coefficient of the "spring" would make an fr difference.. the bending modes would be damped by the glued foam... plus they would not be broadband even if unglued as it would just work at the natural resonant fr

The acoustic engineer I worked with just used 1mm steel on 100mm foam that was more springy than bassotech ... he was shooting for below 100hz

This is why I prefer corner bass traps

This book have many information about CPA (VPR) , There are many application cases inside also.Part 1 of 3

From the eBook, "Applied Acoustics: Concepts, Absorbers, and Silencers for Acoustical Comfort and Noise Control" by Helmut Fuchs, ISBN 978-3-642-29367-2, © Springer-Verlag Berlin Heidelberg 2013. Hopefully reproducing these exerpts won't violate any copyrights... I've highlighted portions I thought were most relevant in yellow.

View attachment 156529

I have this book too , And the Chinese translation of this book was done by Professor Xueqin Zha also.

There is no URLs for Chinese make VPR

Because they're primarily used for anechoic chamber projects, primarily for automotive manufacturers and large corporations.

They're generally not available to private users.

I have some connections in the industry and can purchase them.

That's all I can say.

Similar threads

- Replies

- 39

- Views

- 3K

- Replies

- 4

- Views

- 779

- Replies

- 0

- Views

- 751

- Replies

- 7

- Views

- 959

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |