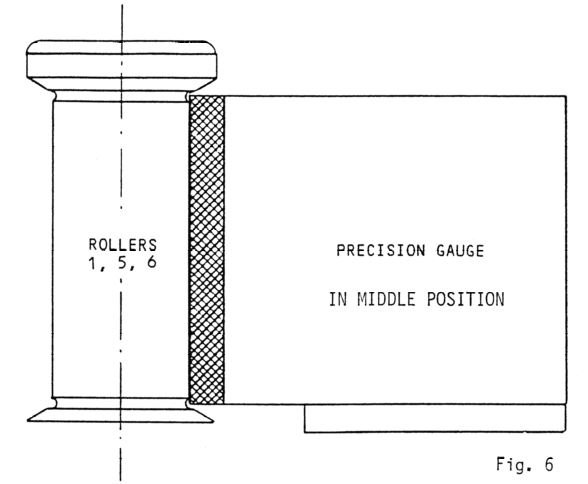

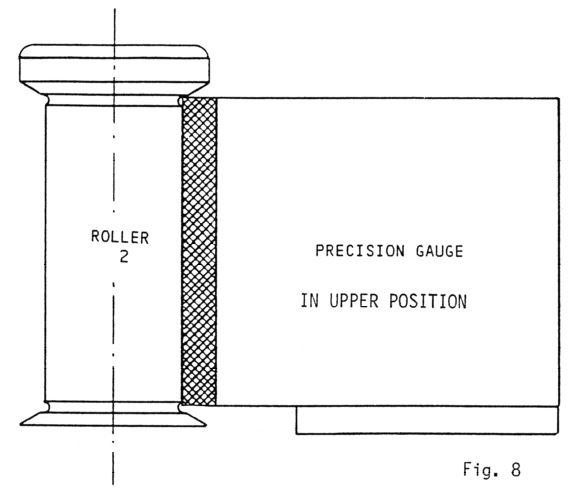

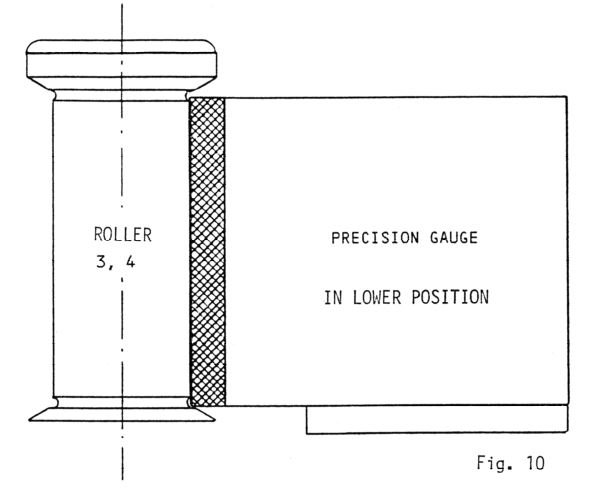

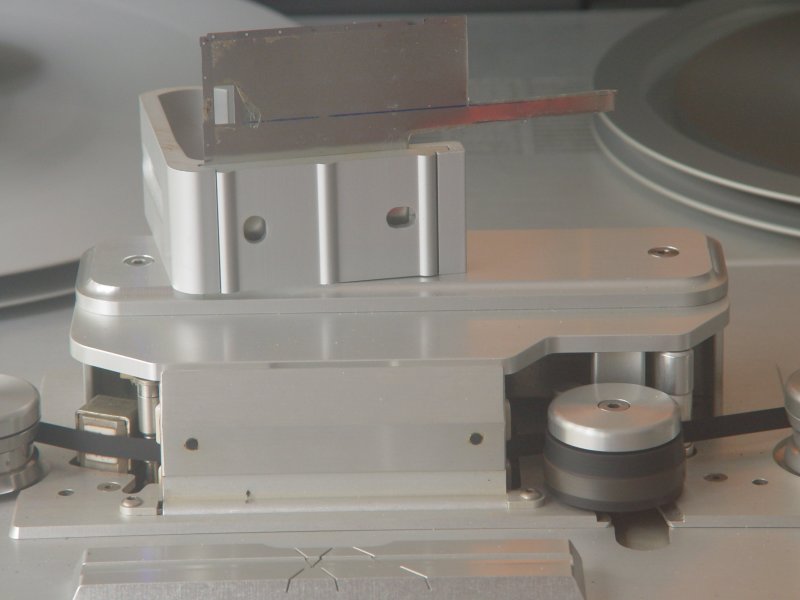

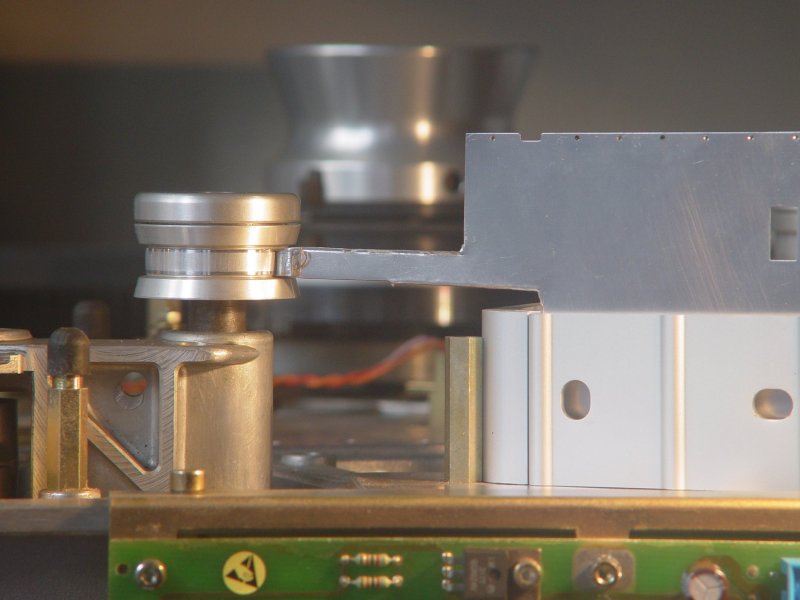

During the pandemic I had some "free time" under quarantine. Browsing some STUDER technical information I spotted an interesting section of checking roller height of STUDER A820 MCH recorder for 2" tape. Driven by curiosity I wondered how good the relative height of my 1/4" A820 rollers would be? SI-110-87's idea was the following: established reference height by placing mechanical gauge on various flat position of A820's die-cast chassis and adjusting each roller by placing combination of shims of various thickness to raise it to the desired height. What really surprise me was that the pre-stablizer roller (roller No.2) was set to be a little bit lower while roller 3 and 4 were set a little bit higher. I guessed it might be specific to 2" tape since at this tape width roller 2 and 3 had to bend the tape against gravity.

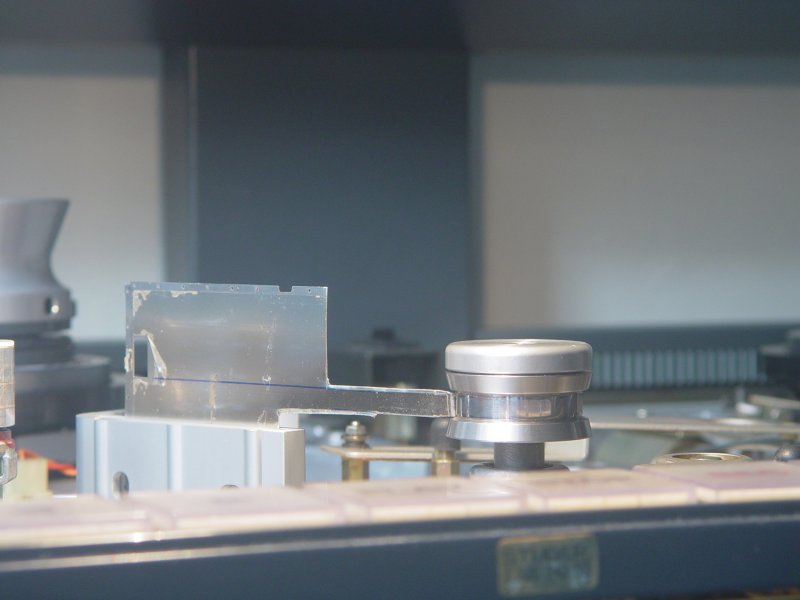

As a regular user we don't have an access for the calibration tool: the precision mechanical block; how can I accomplish this task? I spotted a unused IKEA curtain hanger part lingering around and got an idea: this part have a long flat side and a gap which could firmly grip a thin metal plate. I picked up a broken iPhone display and obtain a thin metal plate. Then I cut it to form a "pointing finger" shape with the "finger width" just be a little bit shorter than 1/4" tape.

Final result was roller 1~6 were all precisely centered; unlike 2" A820 MCH. Maybe it was intended to be so since 1/4" tape was light weight relative to that of 2" tape. Or my gauge's precision was not good enough to resolve the minute difference of roller height of roller 2 and 3/4.

Anyway this interesting experiment made me confident of this 34 years veteran still strongly hold its legendary tape handling on such large chassis base. Also adjusting shims on roller no. 5, the tacho roller, was the only one which can not be tucked between roller shaft and top bearing.

As a regular user we don't have an access for the calibration tool: the precision mechanical block; how can I accomplish this task? I spotted a unused IKEA curtain hanger part lingering around and got an idea: this part have a long flat side and a gap which could firmly grip a thin metal plate. I picked up a broken iPhone display and obtain a thin metal plate. Then I cut it to form a "pointing finger" shape with the "finger width" just be a little bit shorter than 1/4" tape.

Final result was roller 1~6 were all precisely centered; unlike 2" A820 MCH. Maybe it was intended to be so since 1/4" tape was light weight relative to that of 2" tape. Or my gauge's precision was not good enough to resolve the minute difference of roller height of roller 2 and 3/4.

Anyway this interesting experiment made me confident of this 34 years veteran still strongly hold its legendary tape handling on such large chassis base. Also adjusting shims on roller no. 5, the tacho roller, was the only one which can not be tucked between roller shaft and top bearing.

Attachments

-

Gauge.JPG141.6 KB · Views: 12

Gauge.JPG141.6 KB · Views: 12 -

Roller_1_5_6.JPG33.5 KB · Views: 11

Roller_1_5_6.JPG33.5 KB · Views: 11 -

Roller_2.JPG32.1 KB · Views: 11

Roller_2.JPG32.1 KB · Views: 11 -

Roller_3_4.JPG32.8 KB · Views: 11

Roller_3_4.JPG32.8 KB · Views: 11 -

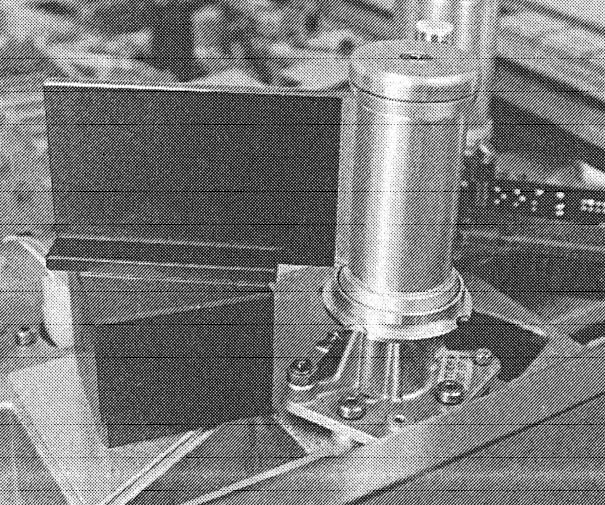

DSC09931.JPG741.8 KB · Views: 12

DSC09931.JPG741.8 KB · Views: 12 -

DSC09932.JPG763.9 KB · Views: 12

DSC09932.JPG763.9 KB · Views: 12 -

DSC09934.JPG344 KB · Views: 10

DSC09934.JPG344 KB · Views: 10 -

DSC09928.JPG419.4 KB · Views: 13

DSC09928.JPG419.4 KB · Views: 13 -

DSC09929.JPG525.1 KB · Views: 12

DSC09929.JPG525.1 KB · Views: 12 -

DSC09926.JPG482.4 KB · Views: 12

DSC09926.JPG482.4 KB · Views: 12

Last edited: