I understand why its not be an easy process and figured that even if I had a new body made, finding someone to install it would be difficult. The removal of the body in the first place is such a precision task that I still ponder why the previous owner took it off to begin with, risking destroying it. I considered maybe it was dropped, and the body was broken. Removal would be easier and the owner would likely assume that it was necessary, but then we talk about that shock you mentioned. Then again, maybe it was an audiophile doing what some can't help but do, which is tweak things that shouldn't be tweaked on the quest for the final 1%. Either way, I basically got it for free, so anything that can keep it alive is considered worth it in my book.That is just the beginning. Next would be to put the assembly into the wood body and glue them together and then align it with precision instruments and an alignment grid. If not perfectly aligned, then you have to do it all over again and maybe even chisel some wood. That is one of the reasons why Koetsu rebuild is expensive, the labor needed for small pieces of components, to remove it , refit it, realign it and repeat the process if something fails to be perfect - skill, instruments, and experience are all needed here. It's not a snap and pop operation by any means. One reason why in my experience, Koetsus can last almost forever (unless you shock it), my Black 8 years, Rosewood Signature 12 years. All sold in working condition when I upgraded.

Koetsu

- Thread starter jadis

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

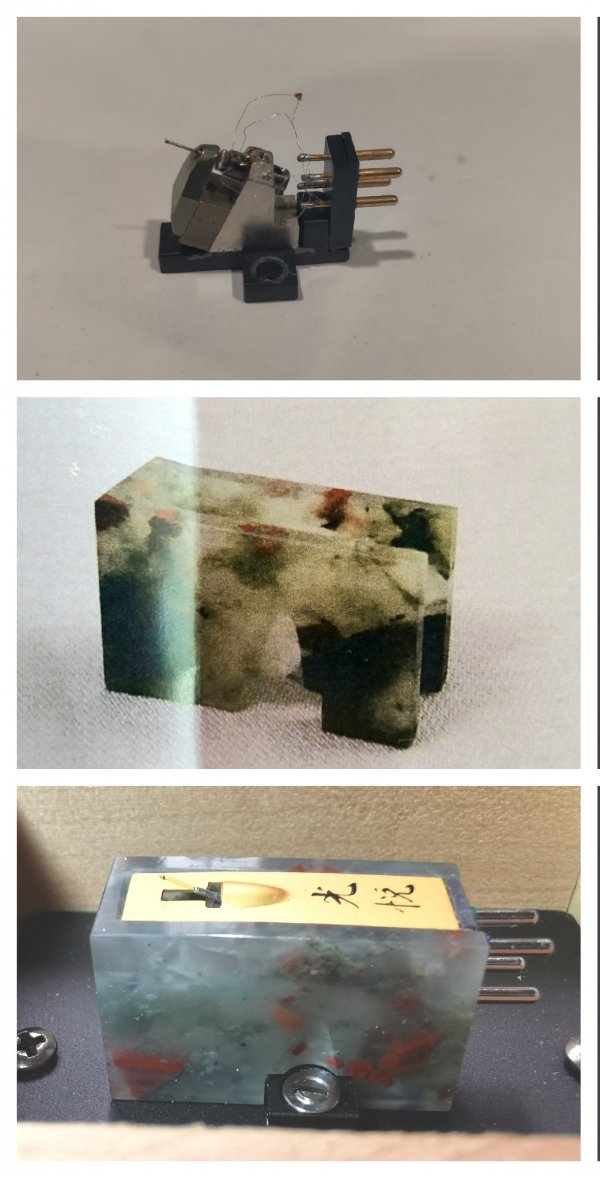

In which case, though not as easy as it sounds, the main task now is to get the 4 dangling wires a bit organized and not touch the record. From there, we will know how it sounds. The pros can do it.I understand why its not be an easy process and figured that even if I had a new body made, finding someone to install it would be difficult. The removal of the body in the first place is such a precision task that I still ponder why the previous owner took it off to begin with, risking destroying it. I considered maybe it was dropped, and the body was broken. Removal would be easier and the owner would likely assume that it was necessary, but then we talk about that shock you mentioned. Then again, maybe it was an audiophile doing what some can't help but do, which is tweak things that shouldn't be tweaked on the quest for the final 1%. Either way, I basically got it for free, so anything that can keep it alive is considered worth it in my book.

As an aside, one of my customers had an Onyx Long Body which he sent to the UK (professional shop) and after many weeks, it was sent back to him. Reason was , the cartridge repairman cannot remove the body without causing some damage to the innards. He sent it to me, and I sent it to the distributor for rebuilt, and all was done in about 3 weeks, with a certificate signed by F. Sugano. Adds to the mystical lore.

Found this picture while searching for some others. Circa 2006 when I started to be the country distributor. All were new stocks except for the Onyx which had no cantilever (for rebuilding), just to make a group shot of the colors of Koetsu then. That particular Blue Lace had the darkest light blue shade I've seen.

good idea, definitely loosen washi paper carefully and look for foreign objects between the coil and the magnets. If you feel confident, clean it carefully. New washi paper is available to purchase.That's a possibility as well, but I would need to have a volunteer use a dial caliper on their body so I could log the dimensions.

Exsample self-adhesive

Congrats,i think In the bottom row the middle would be my favoriteLook what arrived today!

Mine too, and it happens to be the most expensive model in the price list.Congrats,i think In the bottom row the middle would be my favorite

Congratulations! Looks beautiful! As I have the one in the middle… it will be enough if you send me the Vermillion and the SUT… just tell if you need my adress info, hahahaLook what arrived today!

/ Jk

They are looking nice indeed !!

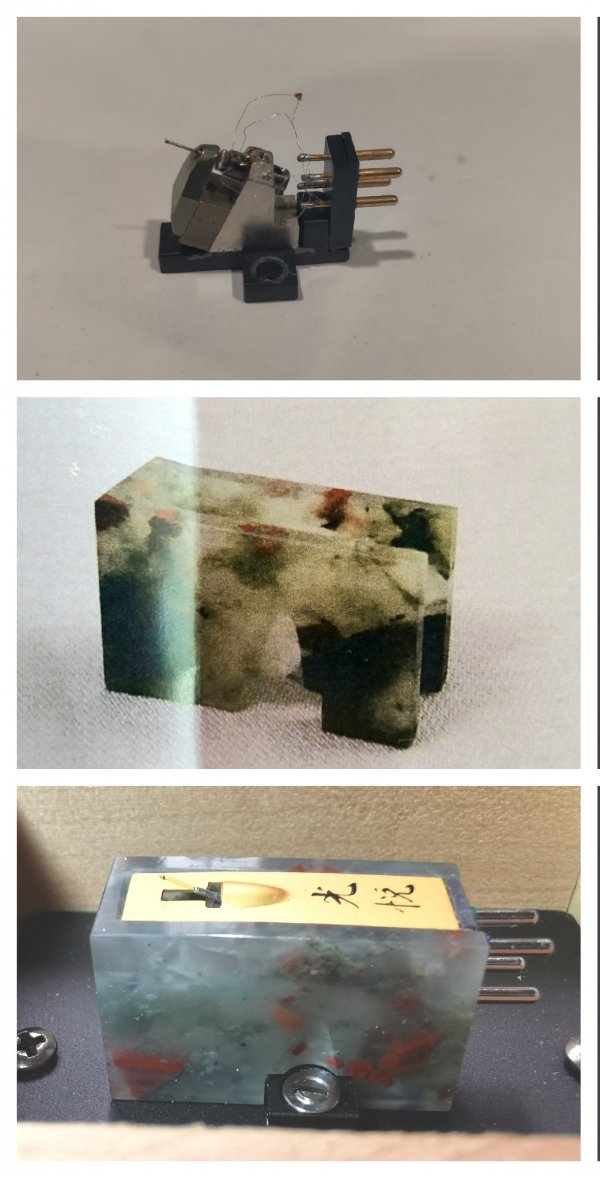

I've always, but with no success, tried to figure out, what the Japanese Characters may mean...

Hence: Can YOU identify, which of these beauties is which ?

--------

?????

Arigat?

-----

Regards

Urs

I've always, but with no success, tried to figure out, what the Japanese Characters may mean...

Hence: Can YOU identify, which of these beauties is which ?

--------

?????

Arigat?

-----

Regards

Urs

Ko ? means light.I've always, but with no success, tried to figure out, what the Japanese Characters may mean...

--------

?????

Arigat?

-----

Regards

Urs

Etsu ? means ecstasy, joy, rapture.

I believe that describes the Koetsu experience, generally.

These 2 characters are Kanji form of writing which the Japanese borrowed and adopted from China centuries ago. And they mean exactly the same thing, but pronounced differently in Chinese speaking places.Ko ? means light.

Etsu ? means ecstasy, joy, rapture.

I believe that describes the Koetsu experience, generally.

Thanks guys

I was actually hoping the find some sort of „Model" distinction on the cartridge or on the box somewhere…

Regards

Urs

PS: MANY, many moons ago, I had to learn a few of these characters: I was visting Japan and had to read the Japanese Rail-Time-Table......

Little did I know, that one day I would spend a small fortune on a "Piece of Jewel", that plays heavenly music

I was actually hoping the find some sort of „Model" distinction on the cartridge or on the box somewhere…

Regards

Urs

PS: MANY, many moons ago, I had to learn a few of these characters: I was visting Japan and had to read the Japanese Rail-Time-Table......

Little did I know, that one day I would spend a small fortune on a "Piece of Jewel", that plays heavenly music

Last edited:

Unfortunately, Koetsu doesn't do that, not even a small piece of paper inside to signify the model name.Thanks guys

I was actually hoping the find some sort of „Model" distinction on the cartridge or on the box somewhere…

Regards

Urs

PS: MANY, many moons ago, I had to learn a few of these characters: I was visting Japan and had to read the Japanaese Rail-Time-Table......

Little did I know, that one day I would spend a small fortune on a "Piece of Jewel", that plays heavenly music

I thought of making a collage of the last 2 steps (based on imagination) on how a Koetsu 'innard' is installed to its body; using Ncolble's nude Koetsu photo as a start, into a blank stone body and how it appears as the final product. The final step after checking the alignment and testing would be the installation of the gold plate cover.

So back when I met my wife, I actually used my cnc machine to make a ring box from polished aluminum and Brazilian rosewood that I used to propose to her. I actually still have the remaining piece of rosewood that is now nearly 10 yrs old. I have considered using the precision of the CNC machine to make a precise replica of a rosewood body.I thought of making a collage of the last 2 steps (based on imagination) on how a Koetsu 'innard' is installed to its body; using Ncolble's nude Koetsu photo as a start, into a blank stone body and how it appears as the final product. The final step after checking the alignment and testing would be the installation of the gold plate cover.

View attachment 116624

Attachments

That's a nice idea!So back when I met my wife, I actually used my cnc machine to make a ring box from polished aluminum and Brazilian rosewood that I used to propose to her. I actually still have the remaining piece of rosewood that is now nearly 10 yrs old. I have considered using the precision of the CNC machine to make a precise replica of a rosewood body.

What's interesting is I've done lots of work with oak and walnut and I now realize how resonant this rosewood is comparatively. To knock this piece with my knuckle makes a sound like a muffled marimba. I was so new to woodworking at the time that I never noticed.

There you are. The secret of the Koetsu Rosewood.What's interesting is I've done lots of work with oak and walnut and I now realize how resonant this rosewood is comparatively. To knock this piece with my knuckle makes a sound like a muffled marimba. I was so new to woodworking at the time that I never noticed.

Similar threads

- Replies

- 57

- Views

- 29K

- Replies

- 26

- Views

- 16K

- Replies

- 150

- Views

- 312K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |