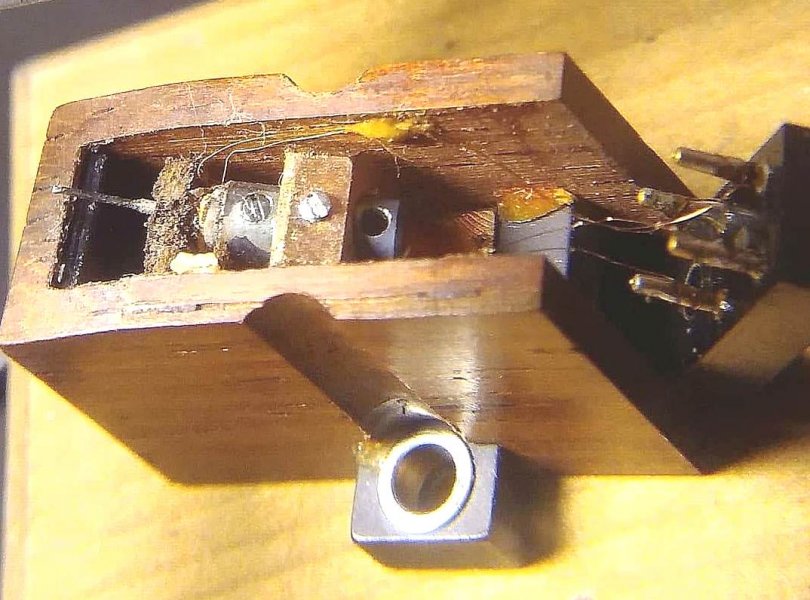

I've seen encrusting on boron, and always assumed it was not a chemical reaction of the boron itself, but rather too much detritus allowed to settle and harden over time atop the boron. Prevention requires rigorous & consistent dry brushing up & down the cantilever as we've been describing. Once any amount of crust has been allowed to solidify it's extremely HARD to get off, perhaps even impossible without professional help. I've got a previously owned RSP in my collection that shows a just a tiny bit of crusting atop the boron. I can't completely knock it off with just dry brushing, BUT the crust stopped growing since I've had it. None of the cartridges I've had since new have been allowed to accumulate any crust.

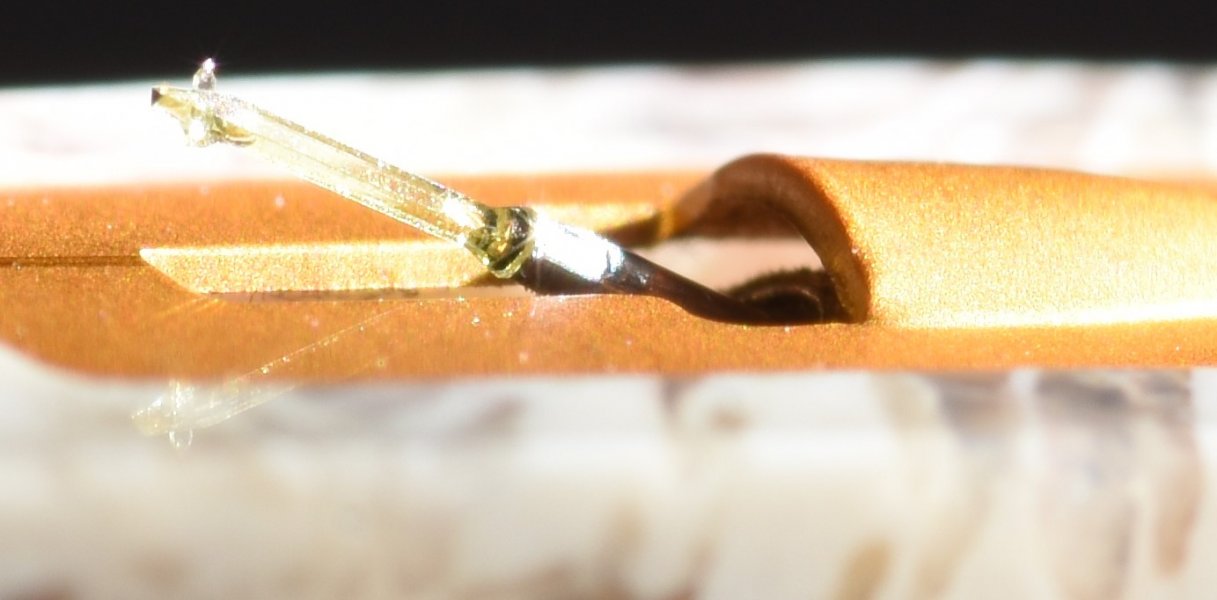

The problem with the front pole plate is it's much more likely to become chemically reactive with the debris "beard" (because it's ferrous which oxidizes like crazy). Over time that results in the very scary pics we saw

Every bit of a proper cleanliness regimen (cleaning the stylus, cantilever, vinyl, good air filtration etc) helps limit or prevent this.

This is why I also hate the "dip only" stylus cleaning methods (Onzow, DS Audio gel, Blu-Tak etc). It's not enough cleaning power to polish the diamond AND it can fool audiophiles into thinking they can neglect cleaning the other cartridge parts. A dry brush MUST be used regularly in conjunction with another method (of choice) to polish the stylus. I like Magic Eraser for polishing the stylus but I don't "just" dip it either (not for everyone to rotationally scrub with it like I do)