if you are not happy with that, use mint protractor. there is no more precise lasered template on the world market.I tried more than 50 attempts over 2 months 3 years ago. They were all in an logical and improved way but no success. I deliberately mentioned industrial printers in my prior post to indicate how far I’ve gone and to eliminate getting responses like this. Of course I’ve tried basic solutions you’ve mentioned but please believe me it’s impossible cause printers are not made for this kind of precision.

Koetsu

- Thread starter jadis

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Exactly. Wally tractor is equally good and more versatile.if you are not happy with that, use mint protractor. there is no more precise lasered template on the world market.

useless for me pivot to spindle dimensions do not fit my tonearms 251.2 and 309.2mm. reviews can be so differentExactly. Wally tractor is equally good and more versatile.

You can use the closest one cause it is impossible to mount a tonearm in 0.1mm precision in terms of pivot to spindle (P2S) distance. I mean even if your tonearm's manufacturer specifies for example a 252.2 mm P2S distance you can not achieve it in practical terms. You can not cut armboard in 0.1mm precision. Feickert, Smartractor or other P2S distance measurement tools have parallax errors besides other errors. Additionally some tonearms have a dent to indicate bearings center but how precisely that dent is coincedes with bearings center is in not certain. On top of that most tonearms don't have this feature.useless for me pivot to spindle dimensions do not fit my tonearms 251.2 and 309.2mm. reviews can be so different

I used Smartractor and Feickert tool before. They're based on measuring P2S distance and setting overhang accordingly. IMHO it is not the best approach cause it contains erorrs which is better explained by @J.R. Boisclair post #13 here.

Long story short: Achieving specified P2S distance is a far fetched effort which can not be practically realized. But P2S is not very important cause effective length compensates it with overhang. You can achieve correct overhang -which is the important parameter- by using a two point protractor or a precisely drawn arc protractor. Some tonearms have a sliding base (SME) which changes P2S distance in order to achieve correct overhang. This is another indication of insignificance of P2S distance compared to overhang. So don't bother if you can not find correct P2S distance on an arc protractor and take manufacturer's P2S spec as a recommendation.

BTW I'm not affiliated with Wally Tools or any other company. Actually I don't agree and debate with @J.R. Boisclair on other topics.

Last edited:

DasguteOhr,

For the 309,2mm arm, you can on the WallyTractor use the 308,8mm or the 313mm curves.

And for your 251,2mm arm you can on the WallyTractor use the 250mm or the 254mm curves.

One or the other would work just fine. WallyTractor will compensate for any deviations.

Zoom in on the picture to see the curves.

/ Jk

For the 309,2mm arm, you can on the WallyTractor use the 308,8mm or the 313mm curves.

And for your 251,2mm arm you can on the WallyTractor use the 250mm or the 254mm curves.

One or the other would work just fine. WallyTractor will compensate for any deviations.

Zoom in on the picture to see the curves.

/ Jk

All fine on my printed template follow the stylus tip over the full length the arc line . A cross comparison with the mintlp Protractor shows the template quite precisely. I don't need a wally protractor you said that would be imprecise but by wally should i accept an error of 1.2mm. I not understand the logic.at the two zero points from the tonearm can align the needle cantilever with the help of the three lines is much more precise than at the outer edges of the cartridge.We both have different ways of setting up a pickup. We are both satisfied, everything is fine.

P. S i have no tonearmboards

P. S i have no tonearmboards

If you are satisfied and happy… then I am very happy for you… and btw, your turntable looks beautiful..All fine on my printed template follow the stylus tip over the full length the arc line . A cross comparison with the mintlp Protractor shows the template quite precisely. I don't need a wally protractor you said that would be imprecise but by wally should i accept an error of 1.2mm. I not understand the logic.at the two zero points from the tonearm can align the needle cantilever with the help of the three lines is much more precise than at the outer edges of the cartridge.We both have different ways of setting up a pickup. We are both satisfied, everything is fine.

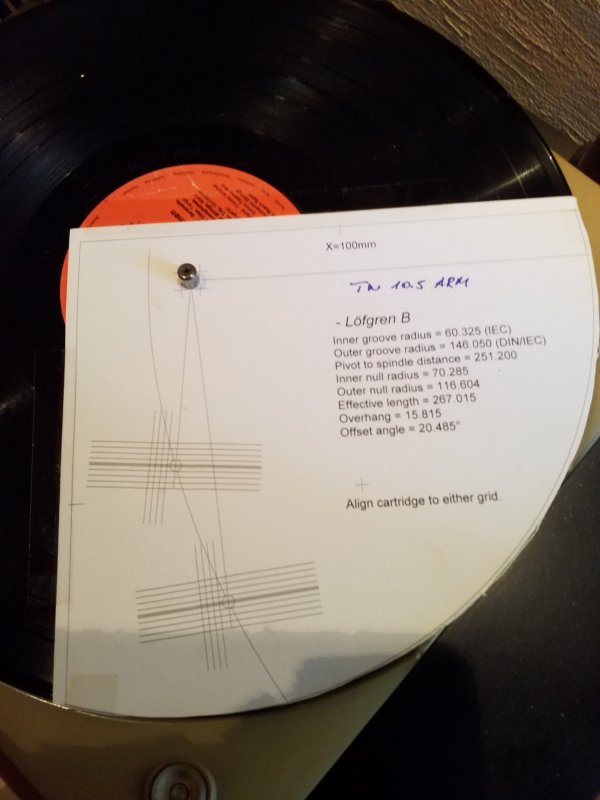

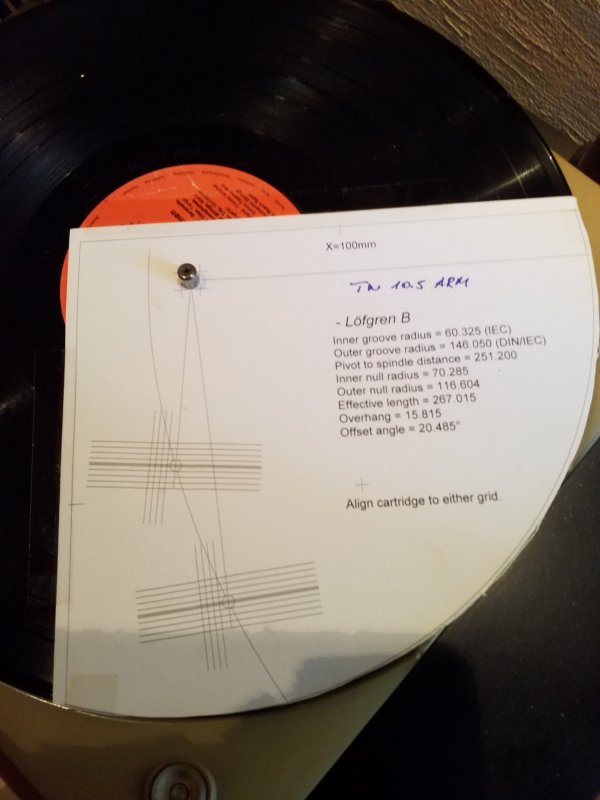

View attachment 109410View attachment 109411

P. S i have no tonearmboards

/ Jk

- 1.2mm error on manufacturer specified P2S distance is not a big deal BUT 1.2mm or even 0.2mm error on OVERHANG is a big deal that ruins the geometry.I don't need a wally protractor you said that would be imprecise but by wally should i accept an error of 1.2mm. I not understand the logic.

- IME Printers make errors on all axises including OVERHANG. Printers don't have constant errors. Error rate changes over paper surface on all axises which makes it impossible to specify a constant scaling. On the other hand a precisely laser etched protractor does not contain errors like printed out counterparts.

- Because of that the print outs contain same scale of errors also on overhang. Even an error like 0.2mm is actually a big error. On the other hand 0.2mm change on P2S causes a significantly low, 0.01mm change on overhang. A big change on P2S distance from 252.2 to 251mm causes only 0.07mm change on overhang. That is the point. Additionally a precisely drawn arc compensates for it. The important thing is to precisely draw an arc (also specifies overhang) not to precisely match P2S distance.

A pressed (not printed) two point protractor is not the best tool but I mentioned it to emphasize even it is better than a wrong print out.at the two zero points from the tonearm can align the needle cantilever with the help of the three lines is much more precise than at the outer edges of the cartridge.We both have different ways of setting up a pickup. We are both satisfied, everything is fine.

If you use a wrong meter to cut the cloth for a dress it will not fit. That is not about having different ways.We both have different ways of setting up a pickup. We are both satisfied, everything is fine.

Last edited:

I've been using a Dennesen Sound Tracktor from the 80s for more than 15 years on my customer installations and so far all have worked fine without any problems. I find the body grid alignment very useful. And I also have a Linn and Stereophile cardboard protractors which act as my secondary checks.I too have faced challenge of aligning a Koetsu with (usually) the very tiny bit of stylus and cantilever you can see past the body. Even the SMARTractor doesn't help much here. The MintLP's markings had the absolute best visibility for aligning Koetsus. But alas, I broke mine and I'm not sure he makes them anymore.

When I'm lazy I'll just use the body to aid alignment if the cantilever is square to it. Quite frankly the results I get with GEODisk are usually just as good as the SMARTractor.

Great discussion. Keep it on.

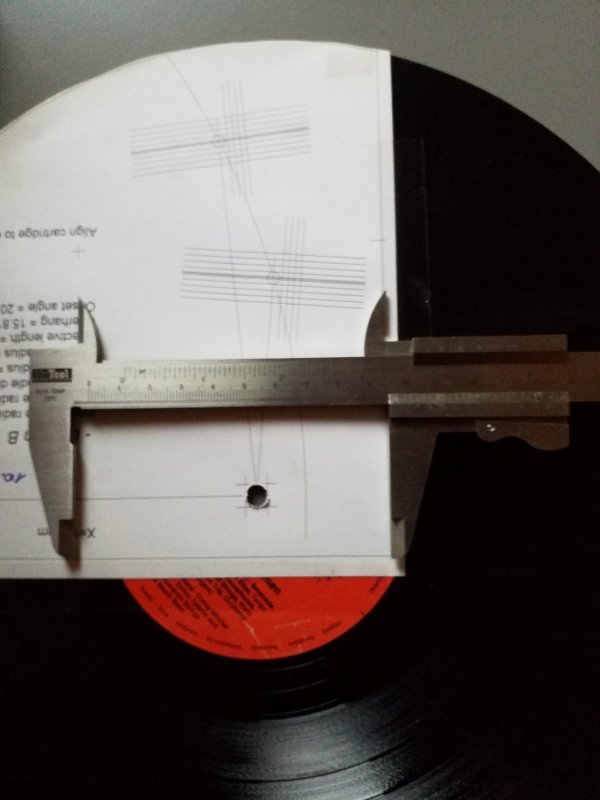

Believe me, before piercing the spindle hole with a fine needle, all dimensions are checked overhang, zero points, dimensions X-Y axis. yes, a printed line is worse than a lasered line. it looks worse under 20x magnification you can see that the ink runs in the paper. I'm picky but the difference to mint lp can no longer be measured.- 1.2mm error on manufacturer specified P2S distance is not a big deal BUT 1.2mm or even 0.2mm error on OVERHANG is a big deal that ruins the geometry.

- IME Printers make errors on all axises including OVERHANG. Printers don't have constant errors. Error rate changes over paper surface on all axises which makes it impossible to specify a constant scaling. On the other hand a precisely laser etched protractor does not contain errors like printed out counterparts.

- Because of that the print outs contain same scale of errors also on overhang. Even an error like 0.2mm is actually a big error. On the other hand 0.2mm change on P2S causes a significantly low, 0.01mm change on overhang. A big change on P2S distance from 252.2 to 251mm causes only 0.07mm change on overhang. That is the point. Additionally a precisely drawn arc compensates for it. The important thing is to precisely draw an arc (also specifies overhang) not to precisely match P2S distance.

A pressed (not printed) two point protractor is not the best tool but I mentioned it to emphasize even it is better than a wrong print out.

If you use a wrong meter to cut the cloth for a dress it will not fit. That is not about having different ways.

@ Jadis

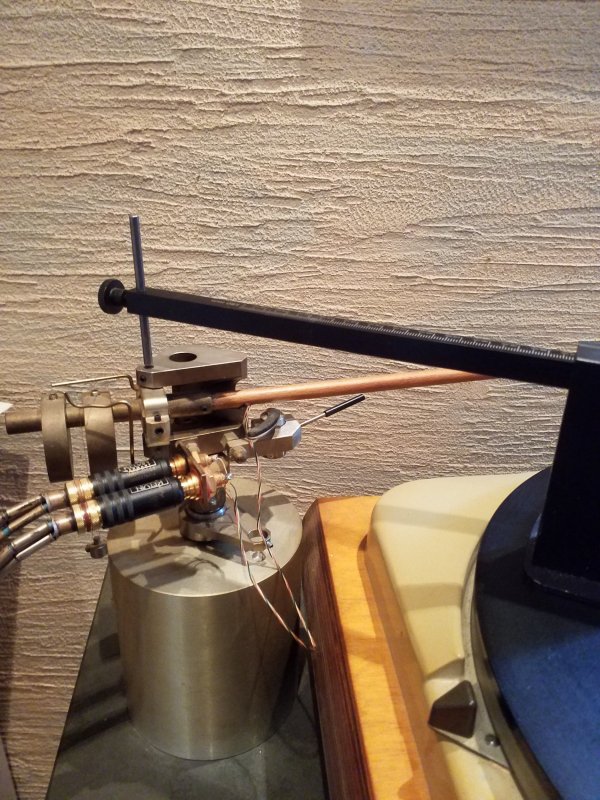

I still have these too . A Schön template, and a dr.feickert.The Feickert is very good if you have the correct pivot point of the tonearm. but mostly difficult to determine. On my DIY tonearm, the bearing point (screw) is the pivot point. perfect match

nevertheless, the printed template delivers the best sound. precise bass, bigger soundstage and with women's voices a cleanliness that the others do not achieve. I hope that detailed enough.

P.S

the more precisely the cantilever is aligned, the oscilloscope image shows much less phase angle L-R chanel

Last edited:

I tried to explain that printers are inconsistent on both axises over paper surface and repeated prints. Which means two consecutive print outs may contain different scales. Their error rate changes over paper surface inconsistently. They’re unreliable. That's why printers are not good for the job.

I did my best but now I give up! Printers are the best for arc protractors.

I did my best but now I give up! Printers are the best for arc protractors.

Last edited:

Thank you, I'm stubborn when something works well for years. I could give you a long list of friends who are very happy with the setup of their tonearms. I hope you're not mad at me now.I tried to explain that printers are inconsistent on both axises over paper surface and repeated prints. Which means two consecutive print outs may contain different scales. Their error rate changes over paper surface inconsistently. They’re are unreliable. That's why printers are not good for the job. I did my best but I give up! Printers are the best for arc protractors.

You have my supportI tried to explain that printers are inconsistent on both axises over paper surface and repeated prints. Which means two consecutive print outs may contain different scales. Their error rate changes over paper surface inconsistently. They’re are unreliable. That's why printers are not good for the job. I did my best but I give up! Printers are the best for arc protractors.

I'm not mad at anybody other than myselfThank you, I'm stubborn when something works well for years. I could give you a long list of friends who are very happy with the setup of their tonearms. I hope you're not mad at me now.

Another ticklish task is brushing off the 'beard-like' dust above the cantilever, on the gold plate itself. That is where dust accumulates most. What type of brush does everyone use?

I prefer Japanese style, nice long & rigid (nylon?) bristles -- good for cleaning up and along the cantilever, and also the front yoke / pole piece. The front pole piece can be hard to access on a Koetsu, but it's even more important to keep that clean than the gold cover because it will attract magnetic dust (really, really bad - catalyst for chemical reactions). Carbon fiber bristles are far too soft and compliant to knock off the really insidious crap.

These kinds of brushes are included on various Japanese products -- Shelter cartridges and Fidelity Research cartridge carriers, in my case. I hear they may also come with Denon cartridges. To clean up a cantilever & yoke I only use a very small section of several bristles, parted from the main body of bristles. Use my 2nd hand to brace holding hand for steadiness.

These kinds of brushes are included on various Japanese products -- Shelter cartridges and Fidelity Research cartridge carriers, in my case. I hear they may also come with Denon cartridges. To clean up a cantilever & yoke I only use a very small section of several bristles, parted from the main body of bristles. Use my 2nd hand to brace holding hand for steadiness.

Great tip, Mike. I have something like that too. Provided by some cartridge brand I now forgot. Lol. I trimmed the brush to have a V shaped gap so I just use the less dense brushes to access that delicate top area. I'll post a photo later. Also, does anyone use an Audio Technica AT 610 liquid brush cleaner? I've used it for 20 years for my Black and Rosewood and Urushi. But right now for use Blue Lace, I've decided to just use a totally dry brush.I prefer Japanese style, nice long & rigid (nylon?) bristles -- good for cleaning up and along the cantilever, and also the front yoke / pole piece. The front pole piece can be hard to access on a Koetsu, but it's even more important to keep that clean than the gold cover because it will attract magnetic dust (really, really bad - catalyst for chemical reactions). Carbon fiber bristles are far too soft and compliant to knock off the really insidious crap.

These kinds of brushes are included on various Japanese products -- Shelter cartridges and Fidelity Research cartridge carriers, in my case. I hear they may also come with Denon cartridges. To clean up a cantilever & yoke I only use a very small section of several bristles, parted from the main body of bristles. Use my 2nd hand to brace holding hand for steadiness.

View attachment 109458

I prefer Japanese style, nice long & rigid (nylon?) bristles -- good for cleaning up and along the cantilever, and also the front yoke / pole piece. The FRONT POLE piece can be hard to access on a Koetsu, but it's even more important to keep that clean than the gold cover because it will attract magnetic dust (really, really bad - catalyst for chemical reactions).

View attachment 109458

By Front Pole Piece, do you mean the end part of the exposed cantilever nearest to the opening of the gold plate?

A little past that - it is hard to access on a Koetsu but easy on (say) a Benz. It is the metal plate with the hole that the cantilever passes through. It's made of magnetically reactive (ferrous) material so it directs and focuses the magnet's field onto the coil immediately behind it.

Similar threads

- Replies

- 57

- Views

- 29K

- Replies

- 26

- Views

- 16K

- Replies

- 150

- Views

- 311K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |