I was working on my house today. Drilling holes for the radiant heat. After a while I need to lay down to rest my body. I flopped on the plywood subfloor, main floor, over my crawl space and lay there. While relaxing I lifted my head and thumped it on the floor. My god it was like a drum strike. Felt like it went through the whole house. It got me to thinking, what are you supposed to do to reduce vibrations through the framing structure of the home. I have about 12 foot spans under the floor between stem walls or exterior walls. 2x10 mixed between 12 inch on center and 16 inch on center. There is blocking inbetween those spans. I was sort of surprised how reverberant that floor was. Hardwoods will be glued to the subfloor. Subfloor is 3/4 plywood. Thoughts????

General Framing Best Practice

- Thread starter Kingrex

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

...do you need a vapor barrier?

You mentioned you want to glue flooring down rather than nailing?

Often, there would be a vapor barrier with a thin felt to help with footfall and moisture. But not always, of course. Sometimes rosin paper is used.

Also possible to have a thin underlayment (like felt/vapor barrier) and glue t&g every foot or so, (glue/no glue) to have a "floating" floor.

Devil is in the details, and things vary from application to application, as you know...especially with regards to moisture, crawl spaces, etc. Not sure if that is helpful, Rex.

You mentioned you want to glue flooring down rather than nailing?

Often, there would be a vapor barrier with a thin felt to help with footfall and moisture. But not always, of course. Sometimes rosin paper is used.

Also possible to have a thin underlayment (like felt/vapor barrier) and glue t&g every foot or so, (glue/no glue) to have a "floating" floor.

Devil is in the details, and things vary from application to application, as you know...especially with regards to moisture, crawl spaces, etc. Not sure if that is helpful, Rex.

The crawl is fully encapsulated and has a dehumidifier in it. Its a conditioned space. The floor is being glued because the installers do not want to hit the hydronic heat piping with staples. The glue will act as a vapor barrier. Not that I want that. Technically, a house is supposed to breath and move vapor around. Vapor barriers cause a lot of mold issues. But it is what it is. Its has to be fully glued. That is a portion of why I encapsulated the crawl. I had to rid that space of moisture.

But that all has nothing to do with the drum like response of the floor. It will probably tame some when the hardwood is adhered to it. But I wondered if there were more that can be done. Mostly because I am going to run into this in my listening space. Its on the same floor system above the garage. I want to get that drum affect out of the framing. Not sure the best way.

Years ago I did a job for a crazy guy who owned a multiplex. He lived in the building too. He wanted to stop noise from floor to floor. He tried a lot of things. He showed me how about 4 to 6 layers of tar paper stack on each other, with the hardwood on top almost completely blocked the sound of a steel ball being dropped on the floor. I don't want that toxic VOC in my space. So that is out.

I wonder about additional blocking with green glue on the sides and the top. Anything to damp the ring.

But that all has nothing to do with the drum like response of the floor. It will probably tame some when the hardwood is adhered to it. But I wondered if there were more that can be done. Mostly because I am going to run into this in my listening space. Its on the same floor system above the garage. I want to get that drum affect out of the framing. Not sure the best way.

Years ago I did a job for a crazy guy who owned a multiplex. He lived in the building too. He wanted to stop noise from floor to floor. He tried a lot of things. He showed me how about 4 to 6 layers of tar paper stack on each other, with the hardwood on top almost completely blocked the sound of a steel ball being dropped on the floor. I don't want that toxic VOC in my space. So that is out.

I wonder about additional blocking with green glue on the sides and the top. Anything to damp the ring.

...understand your points on conditioned crawlspace and heated floor. Space has to be part of the inside or part of the outside. Problems I have seen are when they're some of both environments.

With the underfloor heating, you want good transfer as you know, so not sure what options there would be for sound-deadening products there. Perhaps the floor vendor has product options. Perhaps discuss "floating" floor concept with 2-3 mm felt layer. My thoughts...

With the underfloor heating, you want good transfer as you know, so not sure what options there would be for sound-deadening products there. Perhaps the floor vendor has product options. Perhaps discuss "floating" floor concept with 2-3 mm felt layer. My thoughts...

There is only 3 options you have - weight, decoupling and sealing air leaks

If you want to isolate your listening room from the house, then the best what you can do is to build "box in box" with decoupling from walls/ceiling. Hard to do when house already built.

Partially you can solve problems with floor - isolate it and add mass and seal surround. It is a typical task for construction companies, they know all the standards. You may ask a help from your local guys who build sport building with "sport floor", say for basketball, sure they can offer a solution and products.

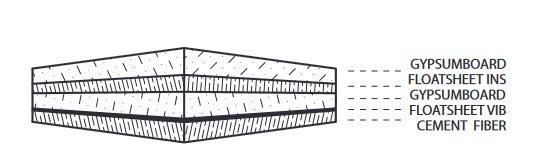

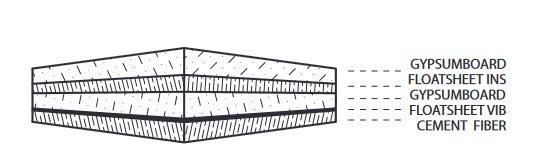

For DIY: double water-proof plaster on with some decoupling and glue parquet on it. A kind of sandwich:

If you want to isolate your listening room from the house, then the best what you can do is to build "box in box" with decoupling from walls/ceiling. Hard to do when house already built.

Partially you can solve problems with floor - isolate it and add mass and seal surround. It is a typical task for construction companies, they know all the standards. You may ask a help from your local guys who build sport building with "sport floor", say for basketball, sure they can offer a solution and products.

For DIY: double water-proof plaster on with some decoupling and glue parquet on it. A kind of sandwich:

Hey Rex… my space is over a crawl, standard construction. When Bonnie spec’d the floor, since I want to have wool carpet in the room, she spec’d a carpet pad that had a layer of mass loaded vinyl attached to the underside of the foam.

When engineered hardwood floors are laid down there can be a thin foam layer already bonded to the boards, or you can purchase foam of varying thickness for just that purpose. A thin layer of mass loaded vinyl might be something you could use between your subfloor and the hardwoods. Considerably more dense and sound deadening than the foam available @ Home Depot.

When engineered hardwood floors are laid down there can be a thin foam layer already bonded to the boards, or you can purchase foam of varying thickness for just that purpose. A thin layer of mass loaded vinyl might be something you could use between your subfloor and the hardwoods. Considerably more dense and sound deadening than the foam available @ Home Depot.

in my previous (one story) home i ended up using a 12' x 18' den as my listening room. it had a 3'-4' tall crawl space below the suspended wood floor. once i realized i had footfall issues with my turntable i explored options to firm up the floor. i ended up pouring 4 concrete 2' x 2' platforms on the bare ground under the floor and bracing under my rack side, and under my speaker end. the last part was using shims to fine tune removing the last bit of flex. cost me about $1500 (in 1998) to have the work done, but no more footfalls, and the bass firmed up.

later i bought a 600 pound air suspension turntable and that would have been a real issue without that bracing.

if you know where your gear and speakers will go it's a real world solution. bracing a whole room is maybe prohibitive. maybe under the rack side you add a third concrete pad for when you walk there. a triangle of beams would be ideal. pouring those pads and installing the beams might be much easier when the floor can be opened up. then later when everything is buttoned up just shim it solid.

later i bought a 600 pound air suspension turntable and that would have been a real issue without that bracing.

if you know where your gear and speakers will go it's a real world solution. bracing a whole room is maybe prohibitive. maybe under the rack side you add a third concrete pad for when you walk there. a triangle of beams would be ideal. pouring those pads and installing the beams might be much easier when the floor can be opened up. then later when everything is buttoned up just shim it solid.

Last edited:

The listening room is above the garage. I can not put more post under it. But I could place a couple beams as the ceiling is 12 feet in there.

I can see mass loaded vinyl helping noise transfer. But would that help footfall.

I can also see that stack of dense material Maxim noted working. No idea what floatsheet is. And sports floors all bounce to reduce wear on players joints. But, a couple layers of drywall with green glue between and plywood on top would be very heavy. Not really more firm. Adding a couple layer of plywood with green glue between would stiffen the bounce?

I can see mass loaded vinyl helping noise transfer. But would that help footfall.

I can also see that stack of dense material Maxim noted working. No idea what floatsheet is. And sports floors all bounce to reduce wear on players joints. But, a couple layers of drywall with green glue between and plywood on top would be very heavy. Not really more firm. Adding a couple layer of plywood with green glue between would stiffen the bounce?

I am roughly here now. The hydronic heat is going in now. I am giving about 6 weeks to complete that. That includes the boiler that is also the domestic water. So 2 birds there. The plumbing will be about another 2 weeks. Its pretty easy as not a lot changed. The electrical about 3 weeks. More to do. A long run to another subpanel. No, not a crazy audio subpanel. Its just kitchen and bath. But, I am going to swap my meter and put in a Meter Main with 8 space distribution. The main 200 amp will go to the existing panel. A new 125 will go to the house subpanel, and a 100 will go to one of my subpanels that will also go to my Torus wall mount.

Attachments

I can see mass loaded vinyl helping noise transfer. But would that help footfall.

Yep, helps a ton.

Yep, helps a ton.

Kingrex,

Once house built it is hard to do sound insulation, as you need to change construction.

Your room proportions: good to know before you start construction, as with a small change in proportions you may get great result.

This is one of the most important things you need to check and it is first step to do. All starts from wall-ceiling-floor reflections.

My suggestions what you can do there is to add double waterproof plaster on top of your veneer with insulation sheets between plaster and veneer. A kind of "floating floor", what will take some energy and absorb it in insulation sheet,

next you glue parquet on top. You will get quite solid construction decoupled with veneer floor, say about 25-35kg/m2

It will take about 25-30mm, and looks that it will affect doors - you need to rebuild entrances.

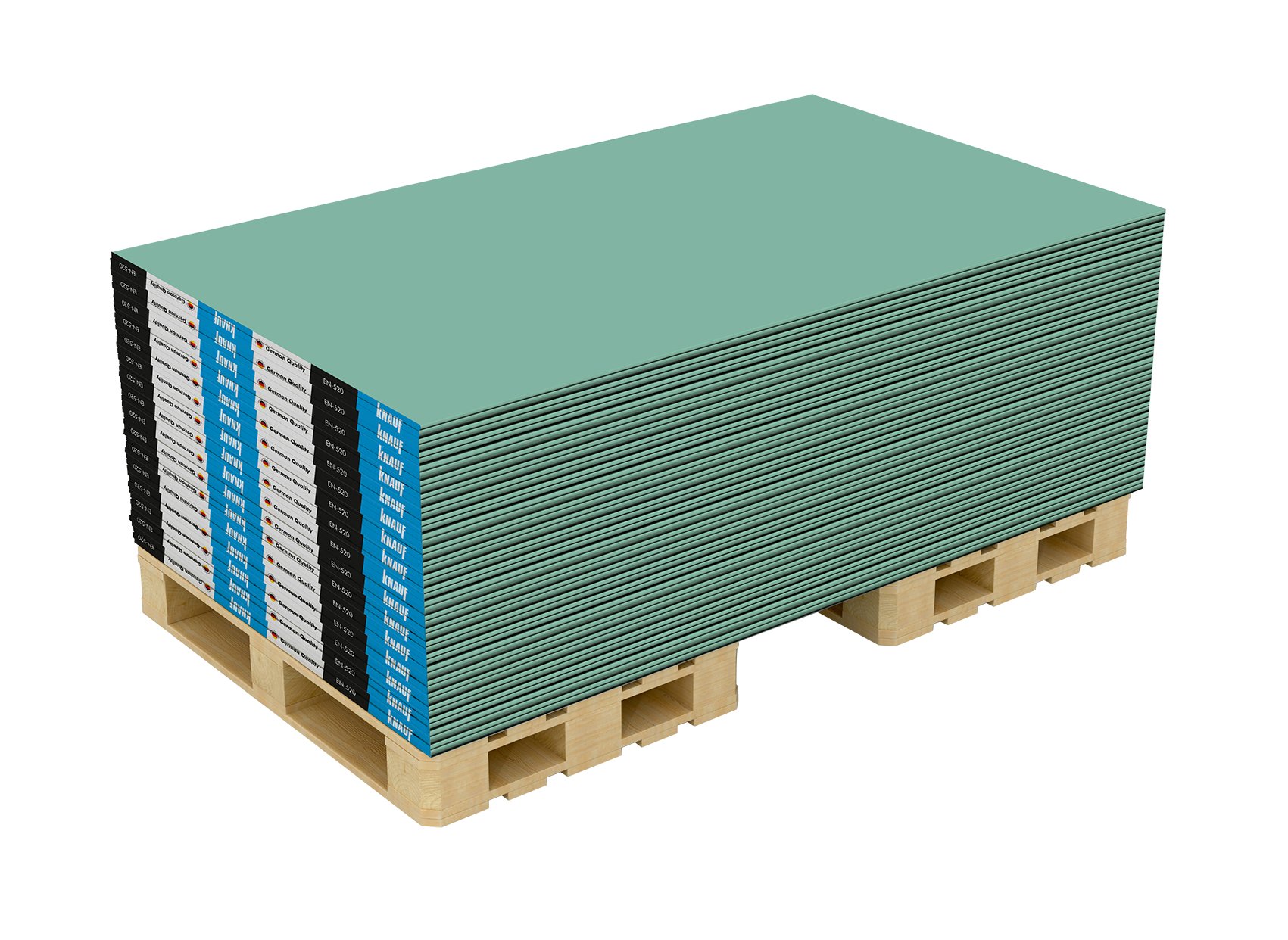

What is often used in my area is Knauf:

knauf.com

knauf.com

For insulation sheets you can go with something like this, just search what you can source locally, as it heavy and shipping will be quite valuable.

Your walls and ceiling: use a damping tape between wood and plaster, something like this: it will do some decoupling.

Make a walls and ceiling with double plaster - we need weight there, otherwise they will work as a tuned bass-traps in the frequencies where we do not need absorption.

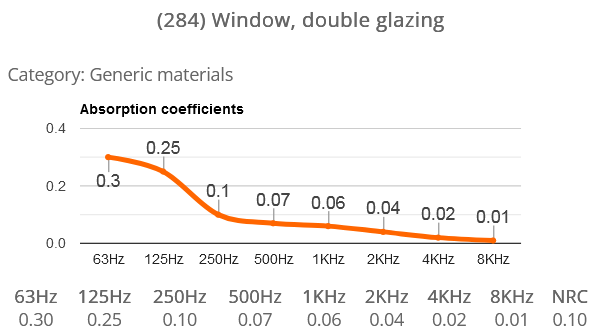

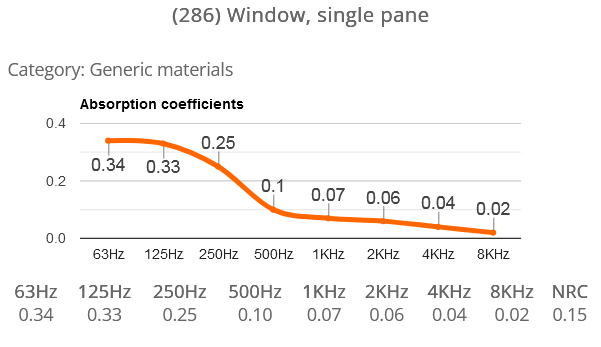

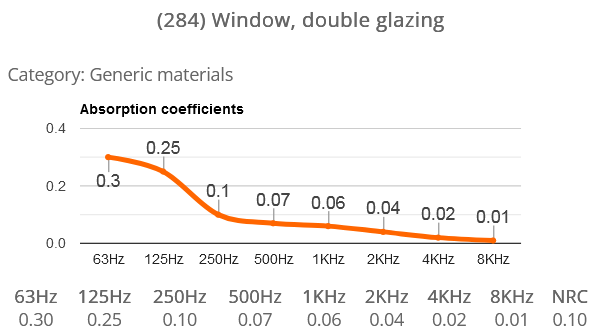

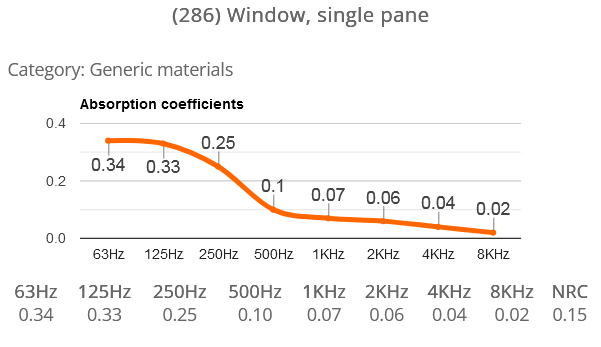

Windows: pay attention to it, they are quite big and will work as a tuned bass-trap. Double, triple glazed will have higher mass and lower absorption and lower frequency.

----------------------------

Once house built it is hard to do sound insulation, as you need to change construction.

Your room proportions: good to know before you start construction, as with a small change in proportions you may get great result.

This is one of the most important things you need to check and it is first step to do. All starts from wall-ceiling-floor reflections.

My suggestions what you can do there is to add double waterproof plaster on top of your veneer with insulation sheets between plaster and veneer. A kind of "floating floor", what will take some energy and absorb it in insulation sheet,

next you glue parquet on top. You will get quite solid construction decoupled with veneer floor, say about 25-35kg/m2

It will take about 25-30mm, and looks that it will affect doors - you need to rebuild entrances.

What is often used in my area is Knauf:

Knauf Moisture Resistant Gypsum Board 9.5mm

Knauf moisture resistant gypsum boards are used in interior wet spaces with relative humidity <=70% (ventillated wet spaces) for partition wall & ceiling application.

For insulation sheets you can go with something like this, just search what you can source locally, as it heavy and shipping will be quite valuable.

Your walls and ceiling: use a damping tape between wood and plaster, something like this: it will do some decoupling.

Knauf Sealing tape for sound decoupling and sound sealing for drywall systems, self-adhesive, sealing tape, especially for metal profiles and substructures, 50 mm x 30 m : Amazon.nl: DIY & Tools

Knauf Sealing tape for sound decoupling and sound sealing for drywall systems, self-adhesive, sealing tape, especially for metal profiles and substructures, 50 mm x 30 m : Amazon.nl: DIY & Tools

www.amazon.nl

Windows: pay attention to it, they are quite big and will work as a tuned bass-trap. Double, triple glazed will have higher mass and lower absorption and lower frequency.

----------------------------

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 24

- Views

- 7K

- Replies

- 0

- Views

- 85

- Replies

- 4

- Views

- 2K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |