"Exclusive" find

- Thread starter morricab

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hello,

I am the owner of a P10, and I am looking for a way to lubrificate the spindle.

Can anyone help me?

And also... il there a way to check the wear of the thrust-pad and eventually replace it?

Thank you

Hello

The P3 is a fully sealed motor unit, so oil lubrication is not required.

I think the P10 may be the same, but not sure.

Is there something wrong with the performance of the P10 that has you looking at lubrication?

Is there something wrong with the performance of the P10 that has you looking at lubrication?

Hello, and thank you for your reply.

My P10 works fine, but I tought that after 40 years there was a need for a few drops of oil (every year on my Technics SP10 Mk2 i refill with just 2 drops of oil).

Also the thrust pad seems to have some sign of wear

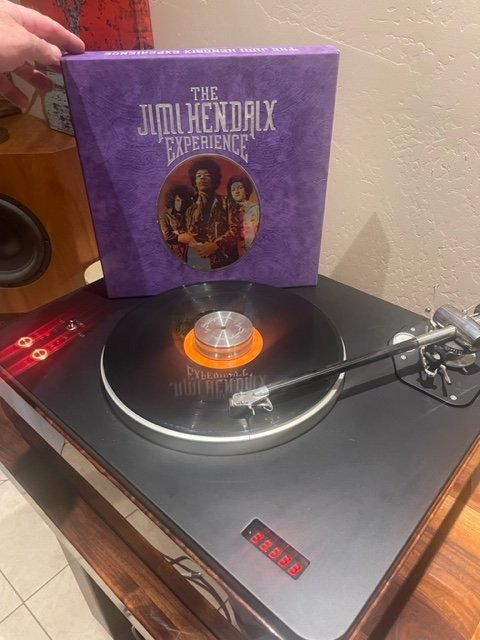

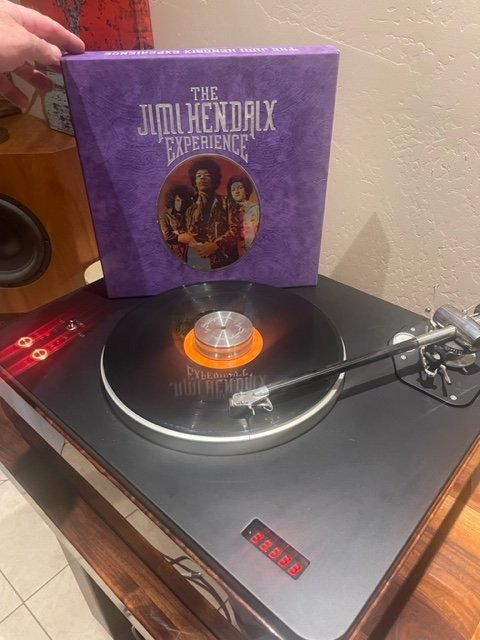

Not much time to work on it. I have a basic plinth and mounted a 12 inch arm (Nottingham space arm) . Waiting now on the repair of my Kiseki Blue cartridge time try it out.Hey Morricab.

We need an update on your Exclusive project.

My P3 is sounding unbelievable atm with a denon 103R with esc ruby cantilever and stulus.

Not much time to work on it. I have a basic plinth and mounted a 12 inch arm (Nottingham space arm) . Waiting now on the repair of my Kiseki Blue cartridge time try it out.

photos please

Hi.

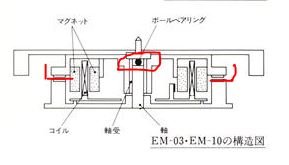

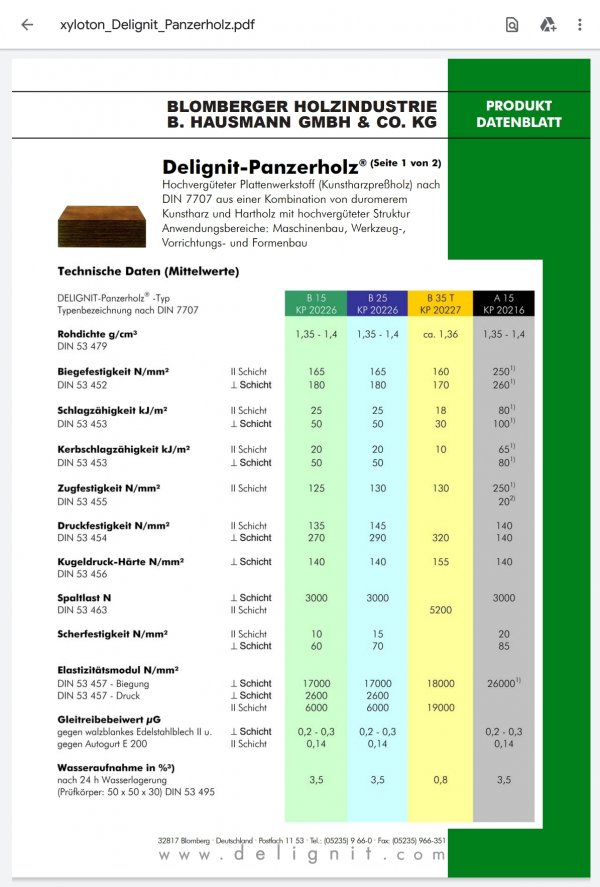

I am owning some P10 and also a P3. I dismanteled both unit completely. The biggest difference are the plinth constructions. The P3 has a double layer one insted the P10 plinth is the one from the PL70. You can buy a EM10 and but 100% in a PL70 plinth. I already did this. The P3 motor has the same dsign as the P3. If some takes the EM10 units, sttipped it down and use a double layerplinth like the design from the P3 you are at the same level. If you want a result, use Panzerholz insted the aluminijm plate in the P3. The stone (schiefer) plate inside the P3 is fine if it will be mounted at the Panzerholz plate. The electronik should be outsorced from the EM10 unit like the one in the P3. It is possible to use an exetrnal housing and so built an analog unit which could take 3-4 tonearms. The will be a killer turntable.

There are not many DD turntables around with a inverse bearing contruction and a platter of around 10kg like the once from the P3 or P10. The platter weight is the complete weight of the sub and upper platter around 9kg.

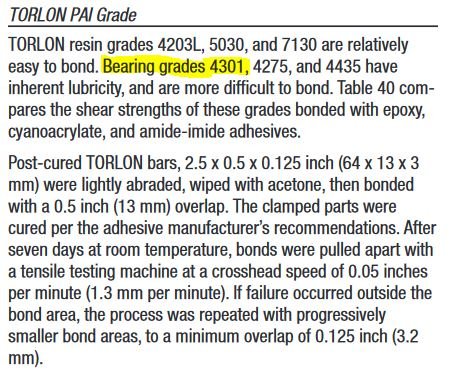

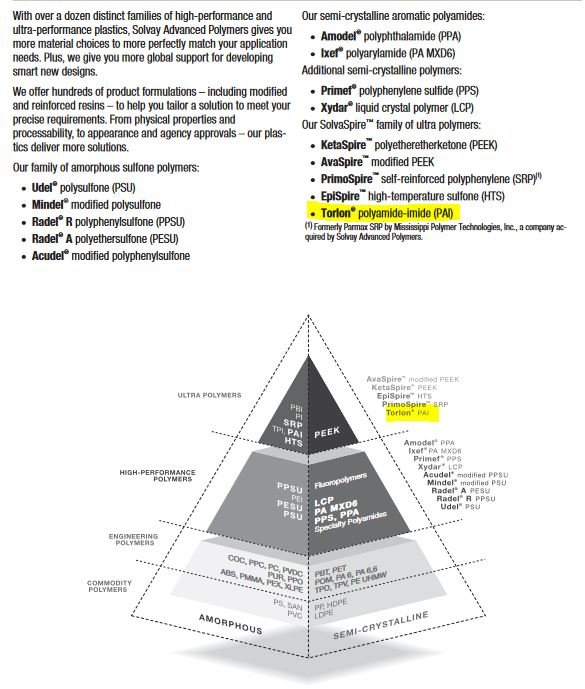

Thereare not many tuning option at this well designed units. Maybe it couod be changed the metall bearing ball and also the plastic of the bearing. Here the Torlon material used in the SP10, maybe has some better technical specs. It is hard to buy a torrlon in the size of the plastic bearing size of the P drivers. I was thinking producing a metal plate where only i the middle the torlon is placed. The new ball bearings are already in my units.

Regards

Rolf

I am owning some P10 and also a P3. I dismanteled both unit completely. The biggest difference are the plinth constructions. The P3 has a double layer one insted the P10 plinth is the one from the PL70. You can buy a EM10 and but 100% in a PL70 plinth. I already did this. The P3 motor has the same dsign as the P3. If some takes the EM10 units, sttipped it down and use a double layerplinth like the design from the P3 you are at the same level. If you want a result, use Panzerholz insted the aluminijm plate in the P3. The stone (schiefer) plate inside the P3 is fine if it will be mounted at the Panzerholz plate. The electronik should be outsorced from the EM10 unit like the one in the P3. It is possible to use an exetrnal housing and so built an analog unit which could take 3-4 tonearms. The will be a killer turntable.

There are not many DD turntables around with a inverse bearing contruction and a platter of around 10kg like the once from the P3 or P10. The platter weight is the complete weight of the sub and upper platter around 9kg.

Thereare not many tuning option at this well designed units. Maybe it couod be changed the metall bearing ball and also the plastic of the bearing. Here the Torlon material used in the SP10, maybe has some better technical specs. It is hard to buy a torrlon in the size of the plastic bearing size of the P drivers. I was thinking producing a metal plate where only i the middle the torlon is placed. The new ball bearings are already in my units.

Regards

Rolf

Last edited:

If Panzerholz would have been available in the past, I am sure Pioneer/Exclusive had been used it for plinth. It is at the moment "one" ofthe best material for turntable plinth. Some expensive producer used it already. Also some modifications with this material are available forTechnics SP10 or other DD motor units (Artisan). A fiend of mine used this material with an Exclusive EM10 motor unit and an Exclusive EA-10 tonearm. He is realy happy with this unit. He also used a SP10 and has some comparisons. Attached is a file with technical informations aboutbthis material Panzerholz. As I know only one company world wide offer this material. There some with closed designed. It is bullet proofed and the physical issues for reducing waves are the same. The multilayer design and high weight together is the best reduction of waves and enrgie caming from loudspeaker or motor. If you nock at this materialyou can hear what is going on.

I also used this material for my SP10 motor unit based plinth (attached some projects unit weight around 50kg).

My next modifications at the Exclusive units are on the bearing with a Torlon pad in the middle of a metal circle (attached pictures).

Regards

I also used this material for my SP10 motor unit based plinth (attached some projects unit weight around 50kg).

My next modifications at the Exclusive units are on the bearing with a Torlon pad in the middle of a metal circle (attached pictures).

Regards

Attachments

-

Screenshot_20230101-141647_Drive.jpg531.3 KB · Views: 31

Screenshot_20230101-141647_Drive.jpg531.3 KB · Views: 31 -

IMG_1930.JPG101.2 KB · Views: 29

IMG_1930.JPG101.2 KB · Views: 29 -

IMG_1935.JPG114.4 KB · Views: 30

IMG_1935.JPG114.4 KB · Views: 30 -

18.JPG1.1 MB · Views: 31

18.JPG1.1 MB · Views: 31 -

sp10_1.JPG23.4 KB · Views: 28

sp10_1.JPG23.4 KB · Views: 28 -

P6150005.JPG710.1 KB · Views: 28

P6150005.JPG710.1 KB · Views: 28 -

2 (2).JPG457.2 KB · Views: 22

2 (2).JPG457.2 KB · Views: 22 -

DSC02820.JPG1.7 MB · Views: 25

DSC02820.JPG1.7 MB · Views: 25 -

WP_20161122_11_00_13_Pro.jpg1.6 MB · Views: 25

WP_20161122_11_00_13_Pro.jpg1.6 MB · Views: 25 -

P6160006(2).JPG2.2 MB · Views: 27

P6160006(2).JPG2.2 MB · Views: 27

Last edited:

You can dismatel the gole unit easily and clean the bearing with a litle alcoholic liquid. The upper plastic bearing is may availible at Pioneer in Japan. The ICs used inside what are special designed for the cirquot are still availble. May contact Pioneer in your country and ask for spare parts.I am the owner of a P10, and I am looking for a way to lubrificate the spindle.

Can anyone help me?

And also... il there a way to check the wear of the thrust-pad and eventually replace it?

Thank you

You have may a technical company near by where you can also ask for a new one. Show yours and the engineers should know the wright material and could make you one easily. May you ask for a Torlon one or a inner circle Torlon piece only. I asked at a mechanical shop nearby for a metal piece and a lillte space in the middle to set a smal round piece made out of Torlon. Torlon is a special plastic with some graphite used also in SP10 and EMT/Thorens spindle bearings.

Attachments

Interesting. What grade of Torlon are you using?You can dismatel the gole unit easily and clean the bearing with a litle alcoholic liquid. The upper plastic bearing is may availible at Pioneer in Japan. The ICs used inside what are special designed for the cirquot are still availble. May contact Pioneer in your country and ask for spare parts.

You have may a technical company near by where you can also ask for a new one. Show yours and the engineers should know the wright material and could make you one easily. May you ask for a Torlon one or a inner circle Torlon piece only. I asked at a mechanical shop nearby for a metal piece and a lillte space in the middle to set a smal round piece made out of Torlon. Torlon is a special plastic with some graphite used also in SP10 and EMT/Thorens spindle bearings.

Torlon 4301. ...but don´t wonder about the prices. It is a realy high end polymer for use in ....What grade of Torlon are you using?

The same PAI 4301 type was used in Japan for Technics SP10 and Thorens/EMT motor bearing pads.

Attachments

Have spent the past 6 Months "reinventing" the P10 and the P3 drives from Pioneer. To answer questions posed above I can confirm that the 2 motors are physically identical in size etc. The P3 has two more components in it namely, a fuse and a diode. Impedance in coils are different and the P3 operates at a higher voltage than the P10. The main difference in the two machines is the control system, both operate at exceedingly tight tolerances as far as rotational accuracy.

Main difference in build up is the P3 is mounted on a spring loaded laminated inner platform - a technique I have implemented in both.

Main difference in build up is the P3 is mounted on a spring loaded laminated inner platform - a technique I have implemented in both.

Using spring like the original system is fine and uefull but an old 80's design. Now you can use great materials with different physical properties as a sandwitch. Sorbothane and other materials have good values to reduce resonances coming from the speaker. This are the most critcal and powerfull energie. The bass has so much energie that it is difficult to reduce this bevore influece the scanning procces during vinyl listening. If this waves influence or set the needle/tonearm in the frequency during playing records and the bass frequenvy is 180° switched because it from the loudspeaker and the viny it could delite itself. This is the reason why most user of cheap turntables do not hear a bass at the vinyl and it is still inside the vinyl. Most light platter construction could be influenced more by bass energie than heavy platter constrsuction like the once from the P3 and 10. I owned a Sony PS-X9 bevor the Exclusive once and even this reduced bass scanning was hearable.

It is also very important to connect the plinth/tonearm or bewring with even one screw to the base. Try this with one screw docking near your tonearm base and "may" you have an effect. This is sometimes small but sometimes very huge. Once I could help someone with a light turntable construction solfing a very huge hum problem in his system only using this kind of plinth and base connection.

It is also very important to connect the plinth/tonearm or bewring with even one screw to the base. Try this with one screw docking near your tonearm base and "may" you have an effect. This is sometimes small but sometimes very huge. Once I could help someone with a light turntable construction solfing a very huge hum problem in his system only using this kind of plinth and base connection.

Last edited:

No problem of bass reduction here on ps x9 on a SRA rack, maybe that is helping or I am not aware of the reduction you are talking about. Measurements show no problems at the bass. I am waiting for xl88d custom to get the best out of my ps x9!Using spring like the original system is fine and uefull but an old 80's design. Now you can use great materials with different physical properties as a sandwitch. Sorbothane and other materials have good values to reduce resonances coming from the speaker. This are the most critcal and powerfull energie. The bass has so much energie that it is difficult to reduce this bevore influece the scanning procces during vinyl listening. If this waves influence or set the needle/tonearm in the frequency during playing records and the bass frequenvy is 180° switched because it from the loudspeaker and the viny it could delite itself. This is the reason why most user of cheap turntables do not hear a bass at the vinyl and it is still inside the vinyl. Most light platter construction could be influenced more by bass energie than heavy platter constrsuction like the once from the P3 and 10. I ownwd a Sony PS-X9 bevor the Exclusive omnce and even this reduced bass scanning was hearable.

It is also very important to connect the plinth/tonearm or bewring with even one screw to the base. Try this with one screw docking near your tonearm base and "may" you have an effect. This is sometimes small but sometimes very huge. Once I could help someone with a light turntable construction solfing a very huge hum problem in his system only using this kind of plinth and base connection.

Attachments

The PS-X9 is a very good build analoge set. It has not a heavy platter and the not existing invers bearing system are technical differences. The Sony unit is a compare product to the Technics SL1000 MK 2 studio unit with the Technics SH-10U phono stage and black EPA toneam included or the german EMT 948/938 units.

But the extreme technical expense of the Excls is distinguish. The bearing of thedual pivot tonearm has synthetic saphiere balls insted metall balls, possibilty tondampnthe tonearm with silikon oil and a lot of more innovative designs differences. I only saw this enormous expense in Da Vinci tonearms before. If you want to build the Exclusive units now I think this will be extraordinary expensive. They also designed IC units only for this motor controll cirquit. I do not know any other company did this bevore. I will realy not critisize a Sony PS-X9 but this thread should be around the Exclsuve once and there arebig advantages in this kind of design using by Exclusive. The Pioneer company also has aside projecg named TAD. This is also a very well known company in a different field of audio. But with an enormous technical and product expense.

In my experience a heavy platter construction could not be compered to a light one. At DD designs it is difficult to increase the platter weight with the same start speed as the lighg once have.

But the extreme technical expense of the Excls is distinguish. The bearing of thedual pivot tonearm has synthetic saphiere balls insted metall balls, possibilty tondampnthe tonearm with silikon oil and a lot of more innovative designs differences. I only saw this enormous expense in Da Vinci tonearms before. If you want to build the Exclusive units now I think this will be extraordinary expensive. They also designed IC units only for this motor controll cirquit. I do not know any other company did this bevore. I will realy not critisize a Sony PS-X9 but this thread should be around the Exclsuve once and there arebig advantages in this kind of design using by Exclusive. The Pioneer company also has aside projecg named TAD. This is also a very well known company in a different field of audio. But with an enormous technical and product expense.

In my experience a heavy platter construction could not be compered to a light one. At DD designs it is difficult to increase the platter weight with the same start speed as the lighg once have.

I replied as your last message was partly about ps x9. I had the chance to try p10 and found ps x9 sounding better, although this is not based on measurements just my subjective opinion. Maybe p10 with better built plinth and other upgrades sound you are talk?ng about make it sound better but in stock form ps x9 sounded better to me. I also hear sl1000mk2 a lot as friends have it and it is not at the same level with ps x9 at all, neither the table nor the arm. Maybe similar tech is involved but the results sound different to me. As a note, when I am listening/testing ps x9 I am not using internal preamp.The PS-X9 is a very good build analoge set. It has not a heavy platter and the not existing invers bearing system are technical differences. The Sony unit is a compare product to the Technics SL1000 MK 2 studio unit with the Technics SH-10U phono stage and black EPA toneam included or the german EMT 948/938 units.

But the extreme technical expense of the Excls is distinguish. The bearing of thedual pivot tonearm has synthetic saphiere balls insted metall balls, possibilty tondampnthe tonearm with silikon oil and a lot of more innovative designs differences. I only saw this enormous expense in Da Vinci tonearms before. If you want to build the Exclusive units now I think this will be extraordinary expensive. They also designed IC units only for this motor controll cirquit. I do not know any other company did this bevore. I will realy not critisize a Sony PS-X9 but this thread should be around the Exclsuve once and there arebig advantages in this kind of design using by Exclusive. The Pioneer company also has aside projecg named TAD. This is also a very well known company in a different field of audio. But with an enormous technical and product expense.

In my experience a heavy platter construction could not be compered to a light one. At DD designs it is difficult to increase the platter weight with the same start speed as the lighg once have.

I love the exclusive series especially the p3 TT and 2401 and 2402 speakers! A vintage shop has a complete exclusive setup and it is sounding really good with c3, m3, p10 and 2402.

Sorry for partial off topic message but I wanted to share my experience.

I dismanteled my P10, P3 and also the EA-03 completely to check all before using ist. The tonearm has also the option of silikon dämping and mostly one of the former user did not clean the box good before giving it the next user. This happend often also with the Audio Craft toneamrs I recived from Japan. In this case of my EA-03 it was also necessary to clean the bearing from old silikon oil. Otherwise I may evaluate nor gave a statement that theEA-03 tonerm of is not so good as... in case of this not known/solved issue.

It is always a pleasure to see and know how well build this units are.

The bearing balls are made from synthetic rubin and I only know the Da Vinci tonearms, used this expensive structure also.

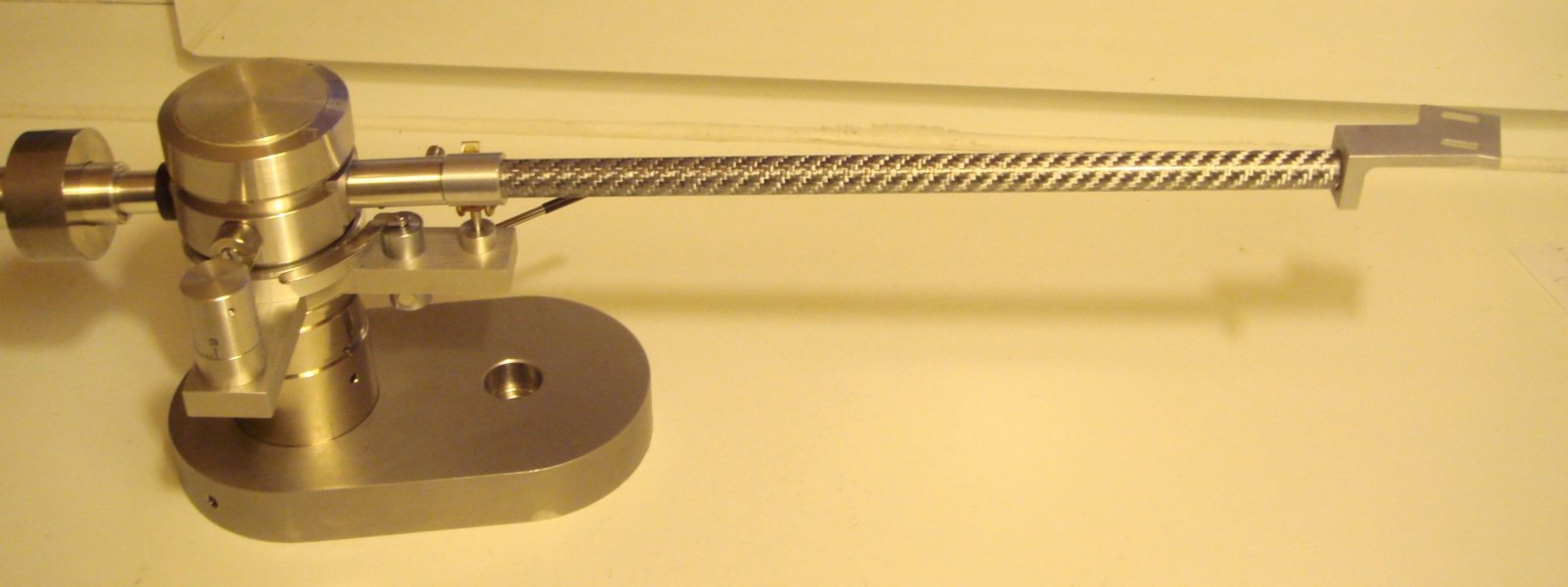

I don´t like the possibility of changing tonearm tubes, because of all this mechanic and electric additional connection. It is always better having none of this than having two of those. I am planing tuning the tonearmtube made of wood or carbon and a new wireing from headshell to 5-din connection unter the toneatm. The tonearm lengh will be 12". The bearing and rest of the EA-03 will be original.

The effective mass of the different structures are very important so I have to check this before making a final decision. Mostly I am using cartridges with a medium compliance of 15 µm/mN like the one from Benz LP/Gullwing.

Maybe the wood tonearm tube will have a higher effective mass, so I have to shorten this or use insted the 12"carbon arme tube.

I think the EA-10 has nearly the some construction and material use.

It is always a pleasure to see and know how well build this units are.

The bearing balls are made from synthetic rubin and I only know the Da Vinci tonearms, used this expensive structure also.

I don´t like the possibility of changing tonearm tubes, because of all this mechanic and electric additional connection. It is always better having none of this than having two of those. I am planing tuning the tonearmtube made of wood or carbon and a new wireing from headshell to 5-din connection unter the toneatm. The tonearm lengh will be 12". The bearing and rest of the EA-03 will be original.

The effective mass of the different structures are very important so I have to check this before making a final decision. Mostly I am using cartridges with a medium compliance of 15 µm/mN like the one from Benz LP/Gullwing.

Maybe the wood tonearm tube will have a higher effective mass, so I have to shorten this or use insted the 12"carbon arme tube.

I think the EA-10 has nearly the some construction and material use.

Attachments

-

1.jpg225.2 KB · Views: 16

1.jpg225.2 KB · Views: 16 -

2.jpg385.5 KB · Views: 16

2.jpg385.5 KB · Views: 16 -

6.jpg205.5 KB · Views: 13

6.jpg205.5 KB · Views: 13 -

DSC02060.JPG474.4 KB · Views: 12

DSC02060.JPG474.4 KB · Views: 12 -

DSC02064.JPG417.7 KB · Views: 13

DSC02064.JPG417.7 KB · Views: 13 -

DSC02061.JPG335.6 KB · Views: 13

DSC02061.JPG335.6 KB · Views: 13 -

DSC02161 (2).JPG252 KB · Views: 14

DSC02161 (2).JPG252 KB · Views: 14 -

DSC02164.JPG529.9 KB · Views: 13

DSC02164.JPG529.9 KB · Views: 13 -

DSC02162 (2).JPG224.9 KB · Views: 13

DSC02162 (2).JPG224.9 KB · Views: 13 -

1.JPG332.1 KB · Views: 16

1.JPG332.1 KB · Views: 16

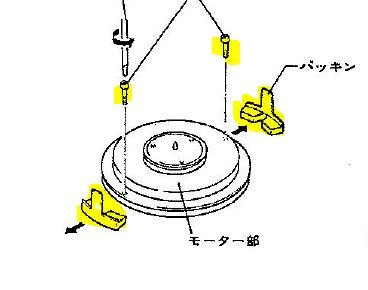

Did you check how deep the "damage" is? It seem the unit was shipped/handeled withou the safty parts for the motor. This two pieces lift the upper part of the motor unit so the metall bearing ball has free moving during transport and is not loaded by the platter weight. After placing the hole unit at the right position this parts has to be removed again so the bearing has a free moving. And the platter sits at the ball bearing again. The two long screws are only to prevent a thrilling during transport.Also the thrust pad seems to have some sign of wear

If you remove the black thin metal platter you can lift uo the upper platter part from the bearing. This black steel sheet is only fixed by 3 smal screws at the side. You may can open them by fingers or a tongs. If you need more help, please let me know I will place detailed pictures.

Attachments

Similar threads

- Replies

- 33

- Views

- 2K

- Replies

- 4

- Views

- 1K

- Replies

- 24

- Views

- 2K

- Replies

- 2

- Views

- 691

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |