The answer to that question is here:That is interesting. Thank you. I will admit to some lack of understanding. Could you please explain what makes one tone arm under hung and the other over hung? Is it whether or not the pivot point is above or below the record surface? Or does it have to do with the center of gravity being above or below the record surface? Or is it something else?

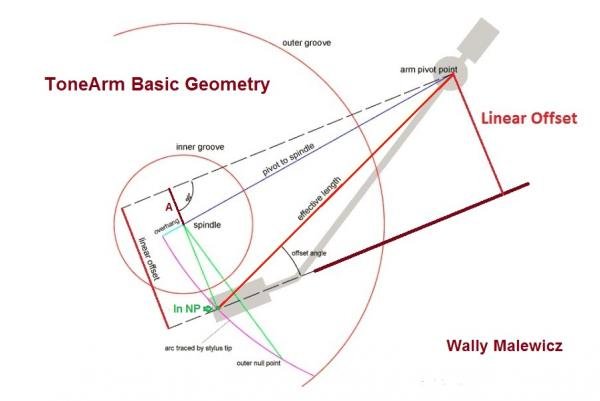

Edit: I think I just learned it is horizontal alignment, and whether the stylus goes beyond the spindle or falls short of it. The effective length versus the pivot to spindle distance.

Sound Bite Series: Skating Force

Sound Bite Series: Skating Force

Share your videos with friends, family, and the world

Watch in sequence