Basis Audio turntable moror replacement?

- Thread starter engadin

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

There is no Basis distributor in Europe these days.

The Basis Synchro Wave, Naim Armageddon, Dr. Fuss Netzteil, VPI SDS and other devices recreate a better sine wave for the AC motor, as far as I know.

I already use such a device; Stromtank for all front end components.

Would an additional device as listed above bring further improvements?

It will not do any harm - I have bough a vintage PSAudio P300 to drive my turntables with synchronous motors in the past. The good thing was that I could adjust voltage for minimal motor vibration.

Motor unit: both caps and the resistor measure ok.

Probably they will measure nice when not operating. Did your engineer measure the voltage across the coils at startup and when stopping?

Now … which power cord for this tt?

Thx for your advice!

A different power cable will not affect the operation of the motor - although it can change the sound of your system, indirectly affecting it, draining noise from the mains.

IMO it is impossible to recommend power cables for turntables, although audiophiles are always eager to recommend their favorites.

I don’t think so. Damn. You had said that before. My fault.It will not do any harm - I have bough a vintage PSAudio P300 to drive my turntables with synchronous motors in the past. The good thing was that I could adjust voltage for minimal motor vibration.

Probably they will measure nice when not operating. Did your engineer measure the voltage across the coils at startup and when stopping?

Not so important if you wanted a real upgrade then a two-phase powersupply is recommended it removes the motor vibration and delivers a clean voltage to both coils.Now … which power cord for this tt?

Thx for your advice!

I think you are right.

But. Which 2 phase power supply to match this unknown motor?

You should first measure the voltage across the motor when it starts spinning again. The rather low value resistor seen in your pics indicates a high voltage motor, perhaps in the 100v+ range.

My preference will be for a directly driven solution and not one using step up transformers. Really not sure what is commercially available. It might also be possible to change the motor for a low voltage 24v type where 2 phase power supplies are a lot more readily available.

As for the phasing cap quality that was discussed earlier on, my experience is a little strange. A long time ago i examined the available options for an old classic turntable. The prevailing engineering opinion is to experiment while adjusting the value in small increments until minimal level of vibrations is achieved. This proved really immaterial according to my ears, compared to the type and dielectric of the capacitor. Disappointingly, after trying a decent selection of otherwise good sounding "audiophile" caps, the winner was the original Siemens, perhaps polycarbonate capacitor. All the caps sounded unmistakably different from each other.

(...) Disappointingly, after trying a decent selection of otherwise good sounding "audiophile" caps, the winner was the original Siemens, perhaps polycarbonate capacitor. All the caps sounded unmistakably different from each other.

In fact, for this purpose we should choose a poor quality capacitor with technically poor dielectric absorption - everything goes for a 50/60 Hz de-phaser and it reduces the RF noise. Some audio designers favor policarbonate over polypropilene capacitors.

I think you are right.

But. Which 2 phase power supply to match this unknown motor?

A 110V type - the 500 resistor should be dropping the voltage around 10V to operate the motor at 100V - a common trick to reduce vibration as torque needs are minimal. Some controllers allow you to adjust amplitude.

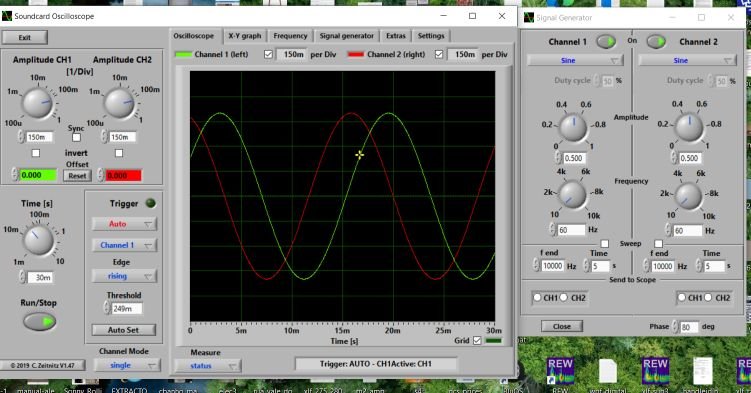

BTW, you can built an excellent controller using an old stereo integrated amplifier, two 12V AC mini transformers and a Windows computer with a sound card (or just having a stereo sound output).

Maybe send the motor box to Dr. Fuss to make a taylor made unit, correct phase angles and all.

All depends on your budget and will. Phase angle is 90 degree.

IMO considering the apparent quality of the motor you should avoid overspending in the controller.

For the Windows PC ?Well, next step is a decent power cord.

Direct connection to the motor coils , no cap and resistor needed because the phaseshift is done in the powersupply.Most interesting!

With a 2 phase power supply …

Do I keep caps and resistor in the motor unit?

Do I remove them and connect the 2 phase ps directly to the motor?

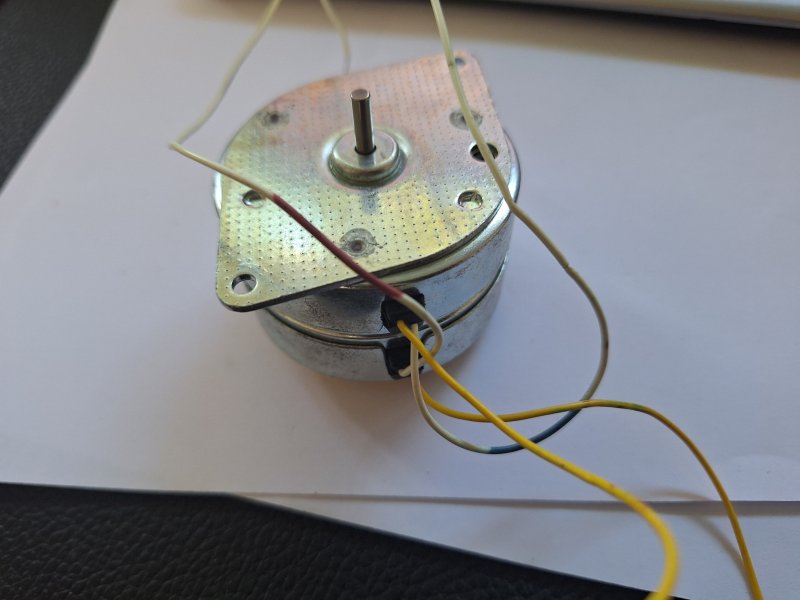

This is a better motor 3mm shaft so the pulley will fit speed can be set at the power supply .My engineer friend seems to have succeeded.

He used super glue to fix the magnet at the shaft again.

Analog music is back again in my home.

Nevertheless, I am still thinking of a better motor and power supply.

Or simply a two phase motor controller.

This is a better motor 3mm shaft so the pulley will fit speed can be set at the power supply .View attachment 158480View attachment 158481

If getting a motor from Berger I would suggest a low voltage type, such as 8 or 12 Vac - it will be much easier to build a two phase a controller.

BTW, can we know why do you consider that the Berger is better than the original motor?

Dr. Bernhard Fuss suggested a lower voltage AC motor as well.

He seems to favor Pro-ject motors.

I would need a new pulley as well for that or use this one:

www.vinylnerds.de

www.vinylnerds.de

He seems to favor Pro-ject motors.

I would need a new pulley as well for that or use this one:

Motor für Pro-Ject RPM 1.3 Genie

Original Pro-Ject Ersatzteil. Motor komplett für Pro-Ject RPM1.3. Teilenummer: 1949576015. Lieferumfang: Motor incl Pulley, ohne Netzteil, ohne…

Dr. Bernhard Fuss suggested a lower voltage AC motor as well.

He seems to favor Pro-ject motors.

I would need a new pulley as well for that or use this one:

Motor für Pro-Ject RPM 1.3 Genie

Original Pro-Ject Ersatzteil. Motor komplett für Pro-Ject RPM1.3. Teilenummer: 1949576015. Lieferumfang: Motor incl Pulley, ohne Netzteil, ohne…www.vinylnerds.de

IMO the pulley is the more critical component in the system - any small microscopic deviation from concentrically will result in wow and flutter. The fit of the pulley to the shaft must be thigh. I had a few spare motors, but was not able to use them as I could not to get the optimal pulleys.

IMO the pulley is the more critical component in the system - any small microscopic deviation from concentrically will result in wow and flutter. The fit of the pulley to the shaft must be thigh. I had a few spare motors, but was not able to use them as I could not to get the optimal pulleys.

This is one of the problems making me hesitate installing a new motor.

Matching belt is next.

Thorens used these motors very reliable mechanical build quality very good close tolerance sinterbushings.If getting a motor from Berger I would suggest a low voltage type, such as 8 or 12 Vac - it will be much easier to build a two phase a controller.

BTW, can we know why do you consider that the Berger is better than the original motor?

For me building a two-phase powersupply for both is no problem stays the same except the extra stepup transformators.

Similar threads

- Replies

- 97

- Views

- 23K

- Replies

- 218

- Views

- 53K

- Replies

- 0

- Views

- 1K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |