Thanks, Ron!

I am happy to share a few more details with you.

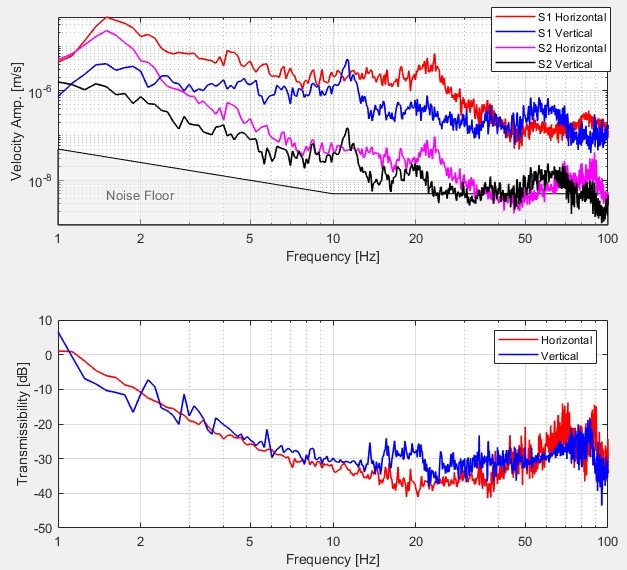

Well, first of all, I believe Herzan isolators are great products. From their transmissibility curves, the performance is excellent. However, a few details like noise-floor and maximum control forces/displacements cannot be seen directly in these graphs.

This is where our isolators should have an edge over Accurion or Herzan: the control forces in our industrial versions (we have to check if audio applications need the same power) are up to 32 Newtons (vertically), while Herzan has 8 N, I believe. Also Herzan is strongly limited in the maximum disturbance. The maximum correction amplitude is 20 µm and above 20Hz it is 2.5 mm/sec (I just checked the TS-150 manual).

The higher control forces and amplitudes will significantly improve the isolation under 'difficult' conditions (building vibrations, operating doors, people moving or jumping around, ...) and also vibrations generated by the device itself (Wow or flutter, ...).

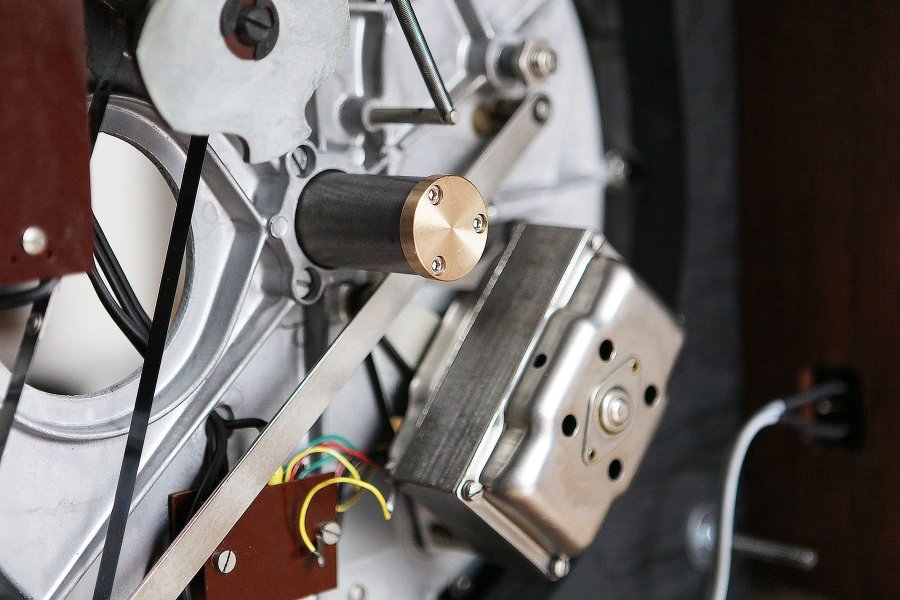

Of course our active control is not noise free But let's say by a careful choice of Op-amps, and especially by designing a sensor with a high sensitivity, we can achive a very promising result. Basically the system was designed from scratch with latest technology and components, and sensors, actuators, electronics and mechanical structure are designed and optimized by a multi-physics mathematical model.

But let's say by a careful choice of Op-amps, and especially by designing a sensor with a high sensitivity, we can achive a very promising result. Basically the system was designed from scratch with latest technology and components, and sensors, actuators, electronics and mechanical structure are designed and optimized by a multi-physics mathematical model.

The key difference might be in the price point. We are considering to sell it for probably less than 3.000 Euro (4.000 USD). Maybe some of you can share the typical prices for Herzan isolators? I believe they are closer to the 10.000 Euro?

I am happy to share a few more details with you.

Well, first of all, I believe Herzan isolators are great products. From their transmissibility curves, the performance is excellent. However, a few details like noise-floor and maximum control forces/displacements cannot be seen directly in these graphs.

This is where our isolators should have an edge over Accurion or Herzan: the control forces in our industrial versions (we have to check if audio applications need the same power) are up to 32 Newtons (vertically), while Herzan has 8 N, I believe. Also Herzan is strongly limited in the maximum disturbance. The maximum correction amplitude is 20 µm and above 20Hz it is 2.5 mm/sec (I just checked the TS-150 manual).

The higher control forces and amplitudes will significantly improve the isolation under 'difficult' conditions (building vibrations, operating doors, people moving or jumping around, ...) and also vibrations generated by the device itself (Wow or flutter, ...).

Of course our active control is not noise free

The key difference might be in the price point. We are considering to sell it for probably less than 3.000 Euro (4.000 USD). Maybe some of you can share the typical prices for Herzan isolators? I believe they are closer to the 10.000 Euro?