Dear

@tima and

@PeterA ,

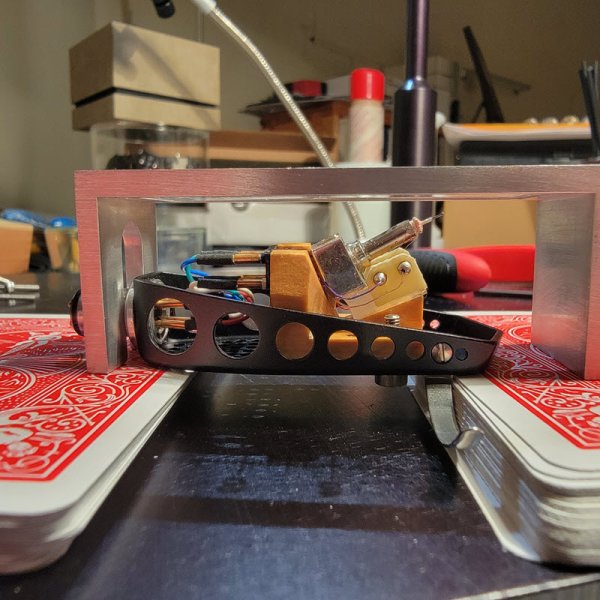

The jig shown in the pictures you shared is designed for aligning a cartridge in a slotted headshell. It can’t be used with slot-less headshells—and more importantly, it’s definitely not suitable for sliding-base arms like the SME.

The idea behind these jigs is to quickly set overhang using the slots in the headshell, assuming a standard distance from the arm collet to the stylus tip. While they’re easy to use, they come with several drawbacks:

- They ignore cantilever deflection under VTF.

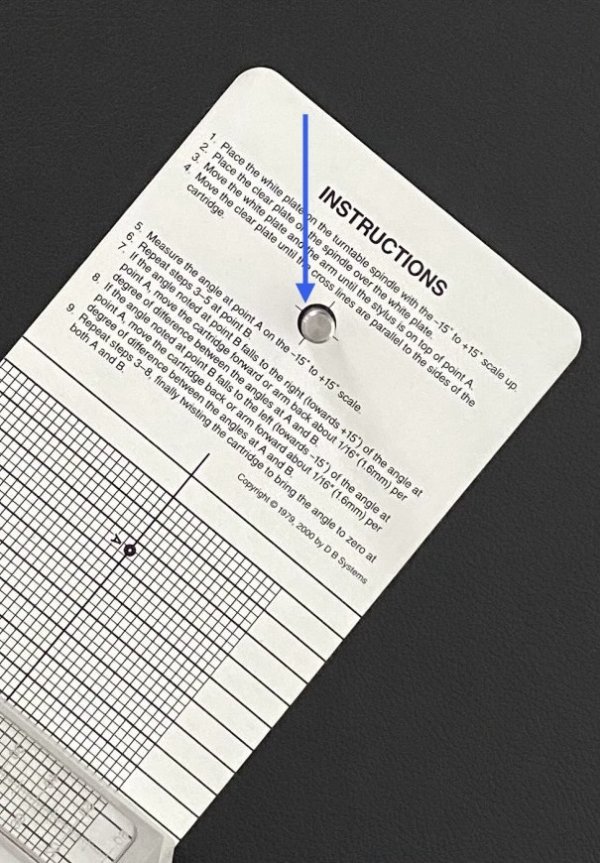

- There’s parallax error due to the distance between the dot on the clear plate and the stylus (as indicated by the blue arrow).

- When the headshell is tightened into the arm collet, the rubber O-ring compresses, affecting the distance between the collet and the stylus. This jig doesn’t account for that. Plus, different arms may screw the headshell in more or less deeply.

- Most importantly, these jigs assume a perfectly accurate Pivot-to-Spindle (P2S) distance is obtained, which is rarely the case. You just can’t drill a hole and mount an arm with 1/10 mm precision. If your P2S is even slightly off, this kind of jig throws everything off.

That’s why these jigs are only used with slotted headshells—for quick and easy cartridge swaps, not for precision alignment. Technics, for example, has offered a similar jig with the 1200 series since the beginning. It aims 52mm from collet to stylus for 15mm Japanese overhang.

View attachment 151901

View attachment 151903

I suggest using a two-point protractor directly, without relying on a jig. It’s free of assumptions, and once you align the cartridge to both null points, you can be confident that the overhang is correct. Jigs always come with assumptions—like “if everything is perfect, the overhang will be correct”—but in reality, that’s rarely the case. Again instead of aligning cartridge parallel to the lines on this jig, aligning cantilever as a continuation of the lines on null points is a better approach because cantilevers are rarely parallel to the cartridge sides. The Smartractor you have is also a good choice in my opinion. I use it with Acoustical System arms.

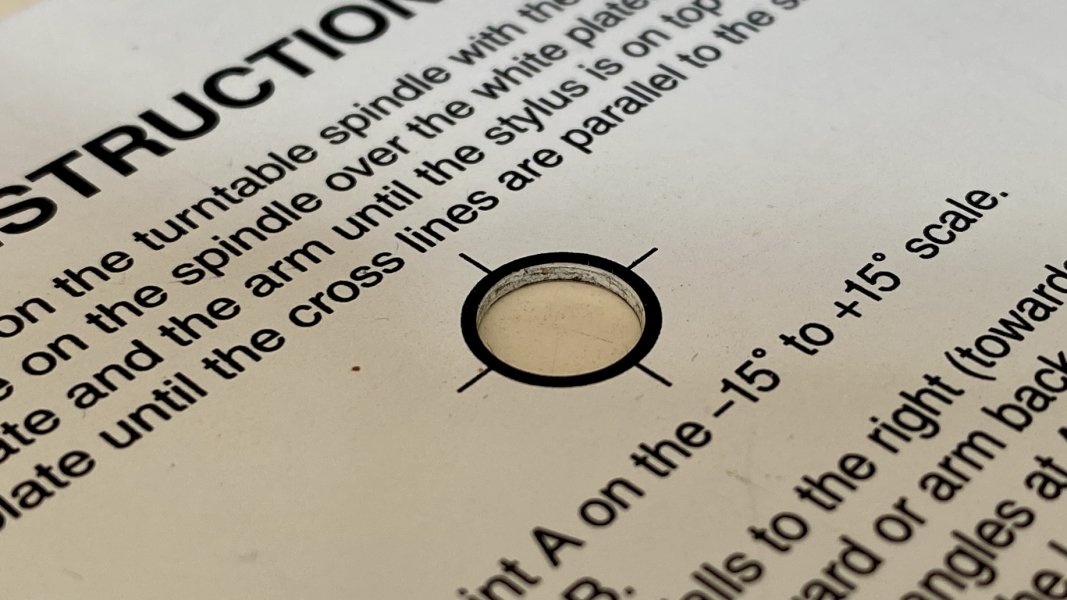

One more thing to watch out for: the spindle hole on most paper protractors is slightly larger than the spindle itself, which can throw off overhang accuracy. It might not seem like a big deal, but the distance between Lofgren and Baerwald geometries is only about 0.5 mm—so small errors can matter.

View attachment 151905

I’d recommend wrapping a bit of adhesive tape around the spindle to bring its diameter closer to the protractor’s center hole, if there’s a mismatch.

Also, just to be clear—my intention isn’t to criticize your approach in any way, just to share my perspective. Like everyone else, it’s entirely up to you to enjoy your setup however you prefer.