Worldwide Wholesales are the North America distributors of Wellfloat

Quantum-Level Vibration Control Established in 2009, WELLFLOAT quickly distinguished itself with its board-type isolators. By employing a robust spring-and-suspension mechanism, the system redirected vertical vibration into controlled horizontal motion—a transformation that significantly reduced resonance and improved isolation performance.

Established in 2009, WELLFLOAT quickly distinguished itself with its board-type isolators. By employing a robust spring-and-suspension mechanism, the system redirected vertical vibration into controlled horizontal motion—a transformation that significantly reduced resonance and improved isolation performance.

Mr.Shiro Nakamura

Wellfloat - the company

In 2015, this principle was further advanced into an L-shaped cantilever structure, adapted from the action mechanism of a full-concert grand piano. The result was a substantial increase in structural rigidity and damping efficiency. This design became the WELLFLOAT standard, subsequently applied to a variety of models. The innovation earned widespread recognition not only from discerning audiophiles but also from professional performers and recording engineers, who valued its measurable and audible improvements.

The refinement also extended into industrial design, featuring the precise styling of Shiro Nakamura—a legendary automotive designer and former CCO of Nissan, who designed many renowned cars including the GT-R. WELLFLOAT products combined functional excellence with an aesthetic appeal suited for the world’s finest audio systems.

Eliminating Vibration-Induced Stress through Pendulum Mechanics

Every audio component generates vibrational energy. As this energy propagates through materials, resonances at various stages create subharmonics—non-linear distortions that manifest as difference tones. Over time, these distortions accumulate, producing a final sound reproduction that is colored and less accurate. What may appear as an increase in “impact” when components are placed directly on a surface is, in fact, the byproduct of distortion emphasizing certain frequency ranges.

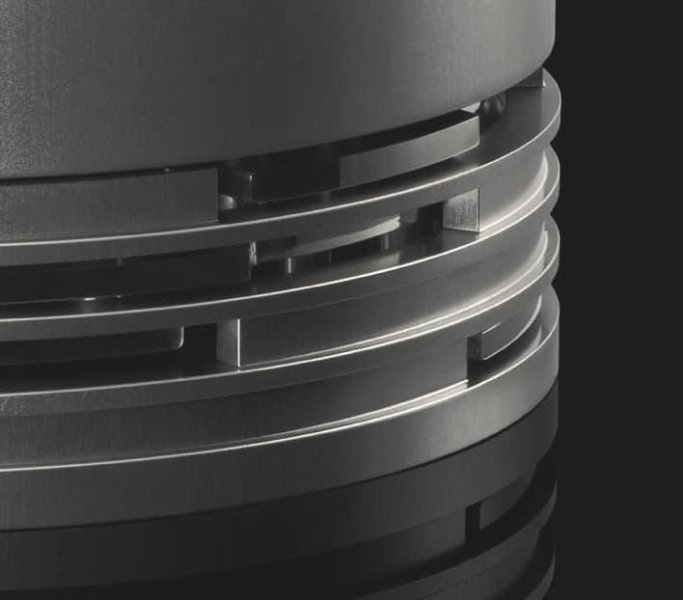

Internal mechanism of Wellfloat Delta Extreme II

Conventional isolation methods—using magnets, rubber, or coil springs—are inherently non-linear in their response. Pendulum motion, however, behaves linearly for small oscillations. This allows impulse responses to be preserved with high fidelity, minimizing phase and harmonic distortion. By applying its unique pendulum-based mechanism, WELLFLOAT delivers vibration isolation with quantum-level precision while avoiding the non-linear side effects characteristic of other methods.

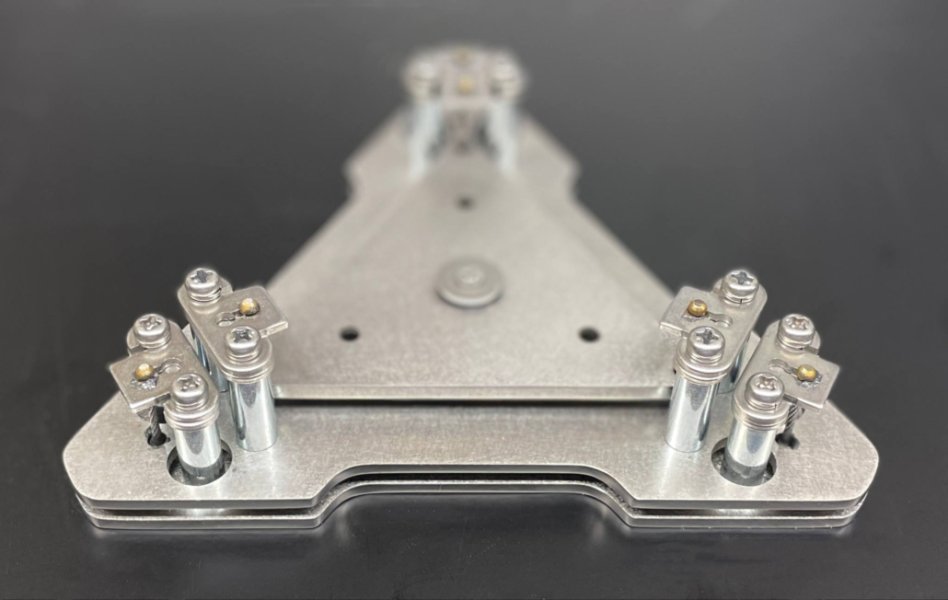

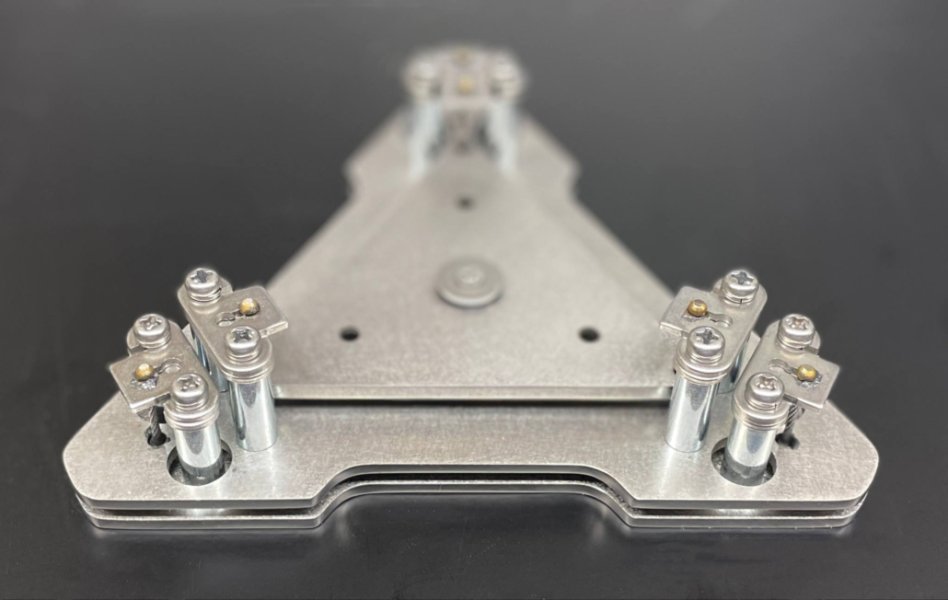

Wellfloat Delta Extreme II

The Pinnacle of Isolation: Multi-Stage Pendulum Technology

In 2022, WELLFLOAT introduced Babel, a groundbreaking four-stage pendulum isolator. Remarkably, this structure mirrors vibration-isolation systems used in gravitational wave observatories, where extreme sensitivity demands unprecedented suppression of external disturbances. Calculations demonstrate that Babel achieves an isolation ratio of approximately 10^16—one part in one hundred quadrillion—an achievement that places it firmly within the domain of quantum-scale phenomena.

Internal mechanism of Wellfloat Babel

Attachments

Last edited: