With the growing interest in ultrasonic cleaning of records, the following information is being provided in the hope of providing some guidance on what is ultrasonic cavitation, what does it look like, what are the design rules for ultrasonic tanks, how do cleaning agents/surfactants play-in, how to manage bath life. The following information has been extracted from this free book - Precision Aqueous Cleaning of Vinyl Records-3rd Edition - The Vinyl Press.

What is UT cavitation and what does it look like? Ultrasonic tanks 'grow' bubbles Principle-of-ultrasound-cavitation-16-The-initiated-bubbles-grow-due-to-evaporation.png (850×553) (researchgate.net) until the bubble collapses. Watch this video between 6:19 and 8:30 Cavitation - Easily explained! - Bing video to see how the bubble collapses. This is going to happen whether the tank has objects in it or not. However, for side firing transducers in a very small tank, like the KLAudio, the Degritter, or the Humminguru, operating without a record or sometime between the transducer's could be a problem.

These are some of the basic design rules for UT tanks.

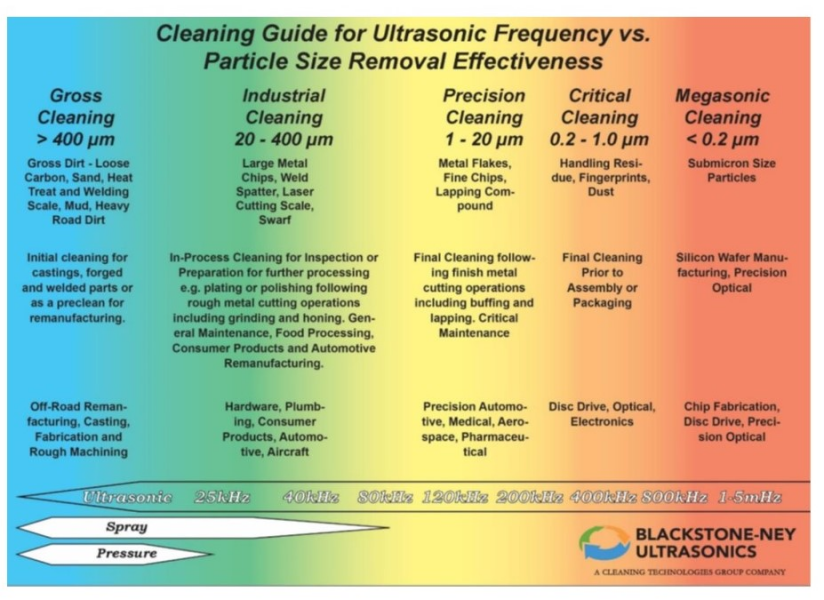

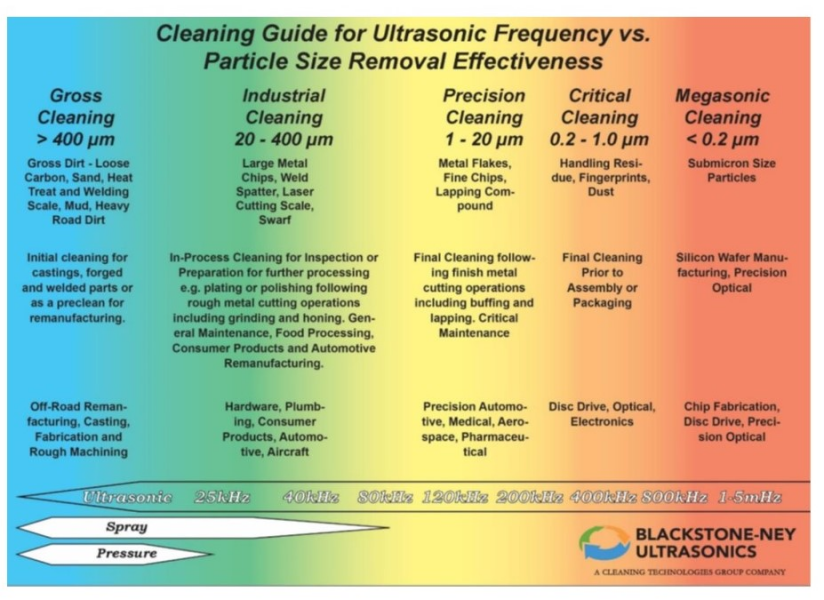

-The power to produce cavitation is proportional to the kHz, so a 120kHz UT needs more power than a 40kHz.

-For ultrasonic tanks, the bubble diameter is inversely proportional to the kHz, so a 40 kHz UT produces a large bubble than a 120kHz UT.

-The cavitation intensity is proportional to the bubble diameter and the tank power (watts/L) but there is a maximum power above which no addition cavitation intensity is obtained.

-The number of cavitation bubbles produced is proportional to kHz, so a 120kHz produces more bubbles than a 40kHz, but smaller bubbles.

-The smaller the tank volume, the more power that is required. It has to do with the ratio of the tank volume to its interior surface area.

-For lower kHz units (<60kHz), if the tank bath flow rate (from filtering or spinning) >50% of the tank volume per minute, cavitation intensity decreases.

-The KL Audio 40kHz 2.5L 200W is a very powerful machine and so is the Degritter 120kHz 1.4L 300W machine. And, given the high power (most of the energy goes ultimately goes to heat) and small volumes, the bath can heat up quickly. The Degritter mitigates this with a cooldown mode if temperature >95F while the latest KLAudio with its external pump/filter system mostly avoids the overheating. But by the experience of others, the high powered Elmasonic P-series UT tanks need a cooler/radiator if high throughput serial cleaning is performed.

-The Elmasonic P-series with its dual frequency 37/80kHz variable power and pulse power for record cleaning is near ideal. The two frequencies can target the different types of soils that may be present with the higher 80kHz targeting the very fine particles and films that the lower frequencies are not as effective. The reason has to do with the boundary layer. The fluid flow at the record (or any) surface develops a static layer that is separate from the bulk fluid that is moving. The boundary layer thickness is dependent on the ultrasonic frequency (high kHz = thinner boundary layer), acoustic energy, and fluid properties (viscosity & density). To get the most effective cleaning, the complete cleaning process has to penetrate the boundary layer to remove the soil and particles that are contained within it. At 40-kHz, the boundary layer can be as thick as 5 microns, while at 120-kHz, the boundary layer can be as thin as 2 microns.

-Lowering the surface tension of the fluid reduces the energy needed for cavitation and can improve cleaning efficiency - better opportunity to penetrate the boundary layer. But there is a delicate balance with using chemistry with UT that can improve the cleaning efficiency more than the small expense to the cavitation intensity (more an issue with low power units). But use too much chemistry or the wrong chemistry and it's all downhill.

-The benefit of the nonionic surfactant Tergitol 15-S-9 is its very high performance. For a no-rinse wetting solution, you want the lowest concentration that will lower the surface tension of the water enough to wet the record.

-A challenge with UT tanks is bath management. If you reuse the same fluid for sequential cleaning the bath will progressively get dirtier after each use. Filtration can extend bath life, but not all filters are created equal. Most soils removed from records using just water or surfactants are not soluble so they can be filtered.

1. The Degritter filter is tiny and is only a simple reticulated foam with pore size at best 80-pores/in (ppi) which is about 150-micron.

2. A 1-micron filter is common, but the very cost units are rated 'nominal' that can pass particles 10X greater.

3. The very best (but require better pumps) are absolute rated meaning they filter >98% at the micron rating and 0.2-micron absolute (that can filter bacteria, but not the surfactant) are readily available and can last upwards of a year, allowing 2 to 4-week bath life.

4. For extending bath life with filtration using water or nonionic surfactant, monitoring with a total dissolved solids meter such as Amazon.com: HM Digital 716160 COM-100 Waterproof Professional Series Combo Meter, 7", White/Purple : Industrial & Scientific is valid. Over time the water TDS will increase from contaminants and absorption of air, replacing at +5-10 ppm above baseline is the general recommendation.

-One option for bath life, is to make your own purified water in large enough quantities to frequently refresh the tank, and that can be done with RO/demineralizer units such as 5 Stage RO/DI Water Filter System - 75 GPD (1-OT-75) | For Fish Tanks, Aquariums, Reef, Water Filtration Machine | RODI – LiquaGen Water. For RO, there is a water usage rate that is 3-4 gallons of water used for each 1-gallon of purified water produced. The ‘brine’ wastewater is disposed to a drain. RO production rates can be impacted by the tap-water inlet temperature and pressure, and filter life will be dependent on inlet tap-water TDS. For homes with higher tap-water TDS, 2-stages of demineralization may be required.

If the above info spurs your curiosity, further details with over 80 linked references is available in this free book - Precision Aqueous Cleaning of Vinyl Records-3rd Edition - The Vinyl Press. Chapter XIV discusses only ultrasonic tank cleaning.

Take care,

Neil

What is UT cavitation and what does it look like? Ultrasonic tanks 'grow' bubbles Principle-of-ultrasound-cavitation-16-The-initiated-bubbles-grow-due-to-evaporation.png (850×553) (researchgate.net) until the bubble collapses. Watch this video between 6:19 and 8:30 Cavitation - Easily explained! - Bing video to see how the bubble collapses. This is going to happen whether the tank has objects in it or not. However, for side firing transducers in a very small tank, like the KLAudio, the Degritter, or the Humminguru, operating without a record or sometime between the transducer's could be a problem.

These are some of the basic design rules for UT tanks.

-The power to produce cavitation is proportional to the kHz, so a 120kHz UT needs more power than a 40kHz.

-For ultrasonic tanks, the bubble diameter is inversely proportional to the kHz, so a 40 kHz UT produces a large bubble than a 120kHz UT.

-The cavitation intensity is proportional to the bubble diameter and the tank power (watts/L) but there is a maximum power above which no addition cavitation intensity is obtained.

-The number of cavitation bubbles produced is proportional to kHz, so a 120kHz produces more bubbles than a 40kHz, but smaller bubbles.

-The smaller the tank volume, the more power that is required. It has to do with the ratio of the tank volume to its interior surface area.

-For lower kHz units (<60kHz), if the tank bath flow rate (from filtering or spinning) >50% of the tank volume per minute, cavitation intensity decreases.

-The KL Audio 40kHz 2.5L 200W is a very powerful machine and so is the Degritter 120kHz 1.4L 300W machine. And, given the high power (most of the energy goes ultimately goes to heat) and small volumes, the bath can heat up quickly. The Degritter mitigates this with a cooldown mode if temperature >95F while the latest KLAudio with its external pump/filter system mostly avoids the overheating. But by the experience of others, the high powered Elmasonic P-series UT tanks need a cooler/radiator if high throughput serial cleaning is performed.

-The Elmasonic P-series with its dual frequency 37/80kHz variable power and pulse power for record cleaning is near ideal. The two frequencies can target the different types of soils that may be present with the higher 80kHz targeting the very fine particles and films that the lower frequencies are not as effective. The reason has to do with the boundary layer. The fluid flow at the record (or any) surface develops a static layer that is separate from the bulk fluid that is moving. The boundary layer thickness is dependent on the ultrasonic frequency (high kHz = thinner boundary layer), acoustic energy, and fluid properties (viscosity & density). To get the most effective cleaning, the complete cleaning process has to penetrate the boundary layer to remove the soil and particles that are contained within it. At 40-kHz, the boundary layer can be as thick as 5 microns, while at 120-kHz, the boundary layer can be as thin as 2 microns.

-Lowering the surface tension of the fluid reduces the energy needed for cavitation and can improve cleaning efficiency - better opportunity to penetrate the boundary layer. But there is a delicate balance with using chemistry with UT that can improve the cleaning efficiency more than the small expense to the cavitation intensity (more an issue with low power units). But use too much chemistry or the wrong chemistry and it's all downhill.

-The benefit of the nonionic surfactant Tergitol 15-S-9 is its very high performance. For a no-rinse wetting solution, you want the lowest concentration that will lower the surface tension of the water enough to wet the record.

- Surface tension of the water is ~72 dynes/cm.

- Surface tension of the record is ~37 dynes/cm.

- 10 ppm (0.001%) Tergitol 15-S-9 reduces the surface tension of water to ~45 dynes/cm.

- 20 ppm (0.002%) Tergitol 15-S-9 reduces the surface tension of water to ~37 dynes/cm. This is enough to 'wet' the record. Wetting the record has the advantage that water runs off the record and does not bead-up on the record significantly quickening the drying time. Drops take a long time to evaporate.

- 52 ppm (0.0052%) Tergitol 15-S-9 reduces the surface tension of water to ~30 dynes/cm. Adding anymore will not lower the surface tension any further and is known as the critical micelle concentration (CMC) and at >52 ppm, and you begin to get detergency.

- 3xCMC (0.016%) for a filtered UT tank will give the full detergency that Tergitol 15-S-9 can give and good bath life.

-A challenge with UT tanks is bath management. If you reuse the same fluid for sequential cleaning the bath will progressively get dirtier after each use. Filtration can extend bath life, but not all filters are created equal. Most soils removed from records using just water or surfactants are not soluble so they can be filtered.

1. The Degritter filter is tiny and is only a simple reticulated foam with pore size at best 80-pores/in (ppi) which is about 150-micron.

2. A 1-micron filter is common, but the very cost units are rated 'nominal' that can pass particles 10X greater.

3. The very best (but require better pumps) are absolute rated meaning they filter >98% at the micron rating and 0.2-micron absolute (that can filter bacteria, but not the surfactant) are readily available and can last upwards of a year, allowing 2 to 4-week bath life.

4. For extending bath life with filtration using water or nonionic surfactant, monitoring with a total dissolved solids meter such as Amazon.com: HM Digital 716160 COM-100 Waterproof Professional Series Combo Meter, 7", White/Purple : Industrial & Scientific is valid. Over time the water TDS will increase from contaminants and absorption of air, replacing at +5-10 ppm above baseline is the general recommendation.

-One option for bath life, is to make your own purified water in large enough quantities to frequently refresh the tank, and that can be done with RO/demineralizer units such as 5 Stage RO/DI Water Filter System - 75 GPD (1-OT-75) | For Fish Tanks, Aquariums, Reef, Water Filtration Machine | RODI – LiquaGen Water. For RO, there is a water usage rate that is 3-4 gallons of water used for each 1-gallon of purified water produced. The ‘brine’ wastewater is disposed to a drain. RO production rates can be impacted by the tap-water inlet temperature and pressure, and filter life will be dependent on inlet tap-water TDS. For homes with higher tap-water TDS, 2-stages of demineralization may be required.

If the above info spurs your curiosity, further details with over 80 linked references is available in this free book - Precision Aqueous Cleaning of Vinyl Records-3rd Edition - The Vinyl Press. Chapter XIV discusses only ultrasonic tank cleaning.

Take care,

Neil