The primitive S1 from my last effort had achieved something other than just good sound. It had restored faith in those closest to me that I could in fact design and build a complete, intentional loudspeaker.

But it still wasn't without a few problems. The series resistor in the speaker was improving bass response, but it was also draining life out of the music, to some degree. It was appreciable when the speaker was paired with any quality tube amplification, and the resistor was removed from the signal path. What's more, if I wanted to offer this driver for sale at some point in the future, the appeal of it would be all but lost if full bass response depended on any kind of provision. No... it had to be right. It couldn't afford to be almost right.

On the other end of the spectrum, the last treble octave still eluded me, due in large part to the high inductance of the driver. And lastly the cabinet, incompletely lined, damped and braced, suffered from mid-cabinet and port resonances.

I'd all but resigned myself to the need for that series resistor, when a friend of mine on the other side of the world made a post to his Facebook group. He had a few extra spools of 0.125mm copper-clad aluminum (CCA) wire, and was willing to part with it for anyone who was interested. I'd already looked into CCA wire in the past, and it could be had... that is, as long as one was willing to order it by the metric ton. If you wanted a small parcel, well... you'd be all but out of luck.

My initial interest in CCA wire was due to its low mass. Aluminum offers a substantial reduction in weight over copper, and as I daydreamed of 20kHz I wanted to shave off every fraction of a gram that I could. I thanked my friend for the offer, ordered a spool of wire from him, and it arrived a week or so later. While strange now to reflect back on it, I had not put a lot of thought at the time into the electrical properties of CCA wire versus copper wire of the same diameter, and how that would influence driver performance.

Aluminum has a much higher electrical resistance than copper, and therefore fewer windings of it are necessary to achieve a target resistance for a given voice coil. That implies a couple of interesting things, both of which seemed to speak perfectly to the problems that I was facing. First, the higher resistance and resulting fewer turns increases the electrical Q (Qes) of the driver. If you recall from the previous post, Qts is a product of both electrical and mechanical quality. That higher Qes meant higher Qts, and much better bass performance without further need for a series resistor to achieve it. The other point of interest was inductance. Voice coil inductance is a result of an electrical signal passing through the windings of voice coil wire. As an inductor, rising frequencies passing through this coil are met with rising impedance, which gradually degrades high frequency output. The fewer the windings necessary, the lower the inductance and rising impedance, and in theory the better the treble extension. I'd lose efficiency in trade, but with lower moving mass I was betting that I'd be on the winning end of that. I set to work winding voice coils with the new wire.

The old copper voice coils weighed about 2 grams each. These new CCA wire voice coils, on the other hand, weighed just 0.6 grams. That 1.4 gram savings may not sound like much, but in this case it represented an impressive 10% reduction in the moving mass, and in the highest octave for a full range driver, mass plays a dominant role.

The previous driver design had a Qts of about .16, but this new design with CCA wire had a magnificent Qts of about .48. With a number like that, I had everything needed to achieve full, unaided bass response. Looking to my other problem, the inductance of the driver, that had been about 1.0. The inductance of the new design was just .67, another significant improvement. It wasn't quite good enough yet, but it was far better.

A faraday ring is a single turn of copper in the form of a ring or sleeve, typically in contact with the pole piece of the magnetic circuit. It's used to lower both driver inductance and distortion, which of course is a good idea. In fact, I'd tried adding one below the voice coil gap in prior versions of the driver, but for reasons that are still a mystery to me it had no meaningful positive effect. Inductance remained little changed, and if the ring had contributed anything noticeable, it had made the driver sound shrill. I'd done something wrong, but couldn't figure out what... poor contact with the motor steel? Ineffective placement relative to the motor geometry? I don't know. In any case, in those efforts I'd ruled out a copper sleeve, because it lies inside the magnetic gap. That necessitates that the gap be wider to accommodate it, which was a non-starter for me. Left without any better ideas however, I turned to faraday rings again to deliver the inductance value I needed.

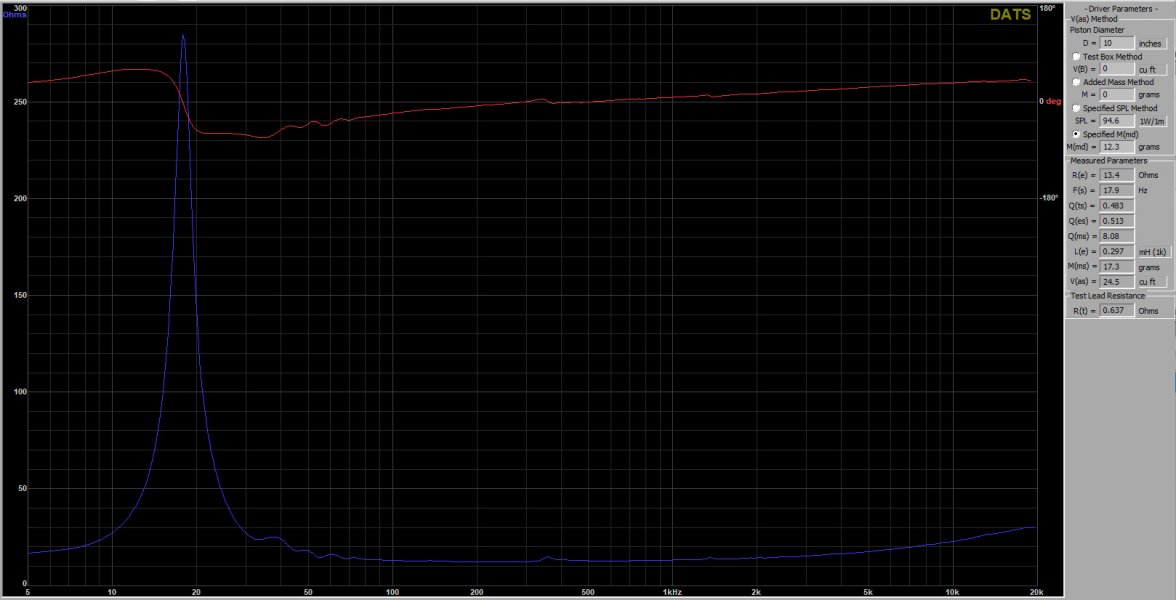

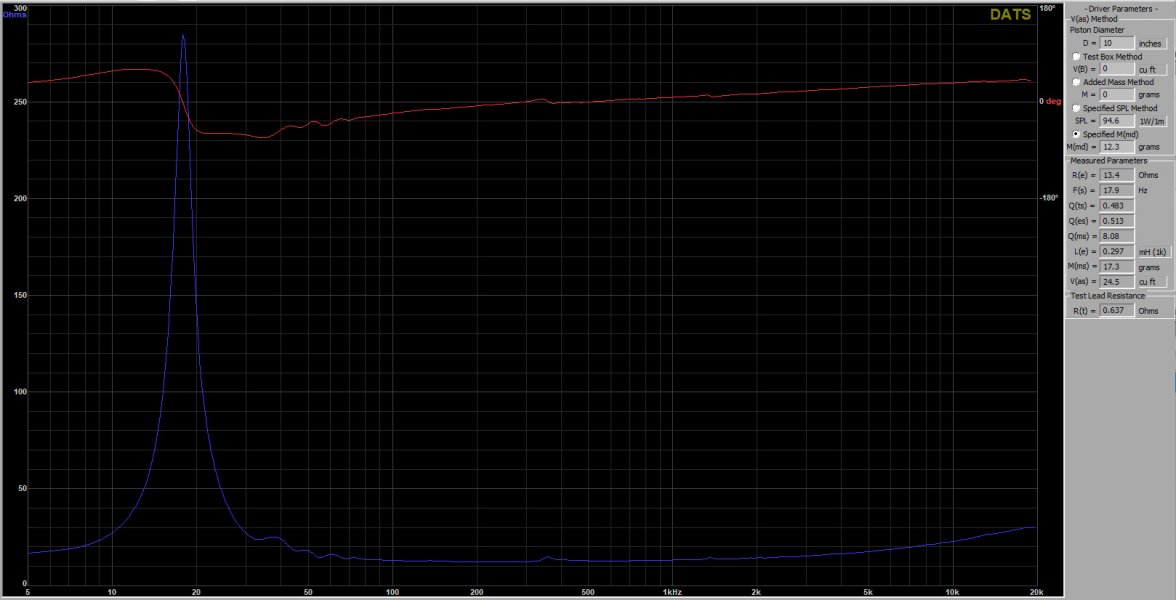

I wasn't going to dance around it this time, however. I replaced the resin phase plug with a milled solid aluminum design inclusive of a channel at the bottom for a thick copper ring, to be added at its base. Interstitial copper foil between the plug, the ring, and the pole piece ensured good contact between them when the plug was screwed down securely to the pole piece. Once again, this new iteration was measured on the bench, and that looked like this:

I'd made it, at last. The efficiency had suffered, as I'd expected, but it was still well within an acceptable range. In combination with the lighter moving mass, I was now sure to get the added treble extension I needed.

Knowing that I had conquered the last of my design challenges, and that this was finally a production-worthy driver, I started to think about naming it. Whatever the name I picked, I didn't intend to suggest hubris. However, I did want to choose something profoundly aspirational... a name that demanded I continue striving to improve my work, whenever I thought of it.

I greatly admire Japanese craftsmanship, and it so happens that my name, Ken, means 'sword' in Japanese. Following that thought, I looked to the Tenka Goken, which are the Japanese katana referred to as the Five Swords Under Heaven. It isn't a part of my branding; the name is really just for me... but from those five great expressions of craft I named the driver Onimaru, which translates to 'The Demon Circle'.

Quoting from an online source, The Onimaru belonged to Hojo Tokiyori, a regent of the Kamakura Shogunate. It got its name because one day it mysteriously moved by itself, falling off the sword stand and in the process engraving an image of a demon (oni) into the leg of the sword stand. This demon engraving looked exactly like the one that was tormenting Tokiyori in his dreams. Afterward, he never clashed with that demon again as he slept, claiming the sword slew the demon and freed him from possession.

I took a week off, and for the first time in ages I really let myself rest. Then, I set to work building a much more worthy cabinet for this Onimaru that I suppose had, in some sense, freed me as well.

But it still wasn't without a few problems. The series resistor in the speaker was improving bass response, but it was also draining life out of the music, to some degree. It was appreciable when the speaker was paired with any quality tube amplification, and the resistor was removed from the signal path. What's more, if I wanted to offer this driver for sale at some point in the future, the appeal of it would be all but lost if full bass response depended on any kind of provision. No... it had to be right. It couldn't afford to be almost right.

On the other end of the spectrum, the last treble octave still eluded me, due in large part to the high inductance of the driver. And lastly the cabinet, incompletely lined, damped and braced, suffered from mid-cabinet and port resonances.

I'd all but resigned myself to the need for that series resistor, when a friend of mine on the other side of the world made a post to his Facebook group. He had a few extra spools of 0.125mm copper-clad aluminum (CCA) wire, and was willing to part with it for anyone who was interested. I'd already looked into CCA wire in the past, and it could be had... that is, as long as one was willing to order it by the metric ton. If you wanted a small parcel, well... you'd be all but out of luck.

My initial interest in CCA wire was due to its low mass. Aluminum offers a substantial reduction in weight over copper, and as I daydreamed of 20kHz I wanted to shave off every fraction of a gram that I could. I thanked my friend for the offer, ordered a spool of wire from him, and it arrived a week or so later. While strange now to reflect back on it, I had not put a lot of thought at the time into the electrical properties of CCA wire versus copper wire of the same diameter, and how that would influence driver performance.

Aluminum has a much higher electrical resistance than copper, and therefore fewer windings of it are necessary to achieve a target resistance for a given voice coil. That implies a couple of interesting things, both of which seemed to speak perfectly to the problems that I was facing. First, the higher resistance and resulting fewer turns increases the electrical Q (Qes) of the driver. If you recall from the previous post, Qts is a product of both electrical and mechanical quality. That higher Qes meant higher Qts, and much better bass performance without further need for a series resistor to achieve it. The other point of interest was inductance. Voice coil inductance is a result of an electrical signal passing through the windings of voice coil wire. As an inductor, rising frequencies passing through this coil are met with rising impedance, which gradually degrades high frequency output. The fewer the windings necessary, the lower the inductance and rising impedance, and in theory the better the treble extension. I'd lose efficiency in trade, but with lower moving mass I was betting that I'd be on the winning end of that. I set to work winding voice coils with the new wire.

The old copper voice coils weighed about 2 grams each. These new CCA wire voice coils, on the other hand, weighed just 0.6 grams. That 1.4 gram savings may not sound like much, but in this case it represented an impressive 10% reduction in the moving mass, and in the highest octave for a full range driver, mass plays a dominant role.

The previous driver design had a Qts of about .16, but this new design with CCA wire had a magnificent Qts of about .48. With a number like that, I had everything needed to achieve full, unaided bass response. Looking to my other problem, the inductance of the driver, that had been about 1.0. The inductance of the new design was just .67, another significant improvement. It wasn't quite good enough yet, but it was far better.

A faraday ring is a single turn of copper in the form of a ring or sleeve, typically in contact with the pole piece of the magnetic circuit. It's used to lower both driver inductance and distortion, which of course is a good idea. In fact, I'd tried adding one below the voice coil gap in prior versions of the driver, but for reasons that are still a mystery to me it had no meaningful positive effect. Inductance remained little changed, and if the ring had contributed anything noticeable, it had made the driver sound shrill. I'd done something wrong, but couldn't figure out what... poor contact with the motor steel? Ineffective placement relative to the motor geometry? I don't know. In any case, in those efforts I'd ruled out a copper sleeve, because it lies inside the magnetic gap. That necessitates that the gap be wider to accommodate it, which was a non-starter for me. Left without any better ideas however, I turned to faraday rings again to deliver the inductance value I needed.

I wasn't going to dance around it this time, however. I replaced the resin phase plug with a milled solid aluminum design inclusive of a channel at the bottom for a thick copper ring, to be added at its base. Interstitial copper foil between the plug, the ring, and the pole piece ensured good contact between them when the plug was screwed down securely to the pole piece. Once again, this new iteration was measured on the bench, and that looked like this:

I'd made it, at last. The efficiency had suffered, as I'd expected, but it was still well within an acceptable range. In combination with the lighter moving mass, I was now sure to get the added treble extension I needed.

Knowing that I had conquered the last of my design challenges, and that this was finally a production-worthy driver, I started to think about naming it. Whatever the name I picked, I didn't intend to suggest hubris. However, I did want to choose something profoundly aspirational... a name that demanded I continue striving to improve my work, whenever I thought of it.

I greatly admire Japanese craftsmanship, and it so happens that my name, Ken, means 'sword' in Japanese. Following that thought, I looked to the Tenka Goken, which are the Japanese katana referred to as the Five Swords Under Heaven. It isn't a part of my branding; the name is really just for me... but from those five great expressions of craft I named the driver Onimaru, which translates to 'The Demon Circle'.

Quoting from an online source, The Onimaru belonged to Hojo Tokiyori, a regent of the Kamakura Shogunate. It got its name because one day it mysteriously moved by itself, falling off the sword stand and in the process engraving an image of a demon (oni) into the leg of the sword stand. This demon engraving looked exactly like the one that was tormenting Tokiyori in his dreams. Afterward, he never clashed with that demon again as he slept, claiming the sword slew the demon and freed him from possession.

I took a week off, and for the first time in ages I really let myself rest. Then, I set to work building a much more worthy cabinet for this Onimaru that I suppose had, in some sense, freed me as well.

Last edited: