I have always wanted to understand the math behind alignment conventions, and having found no source, I did the math myself.

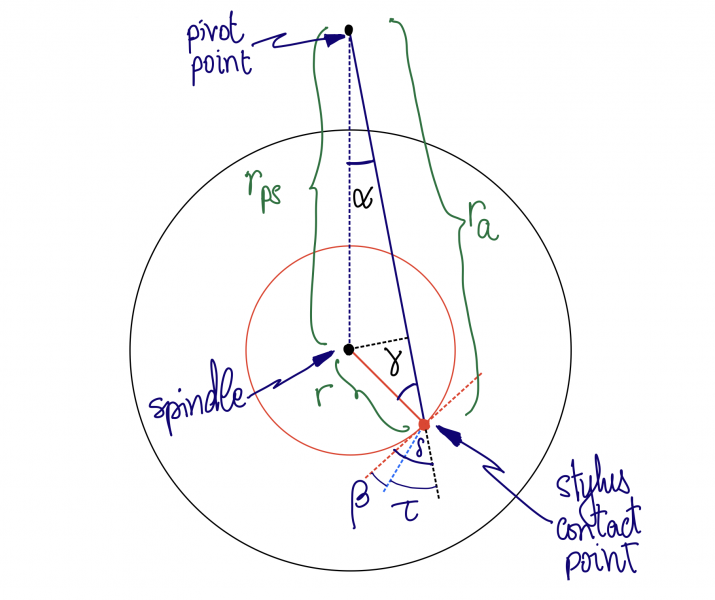

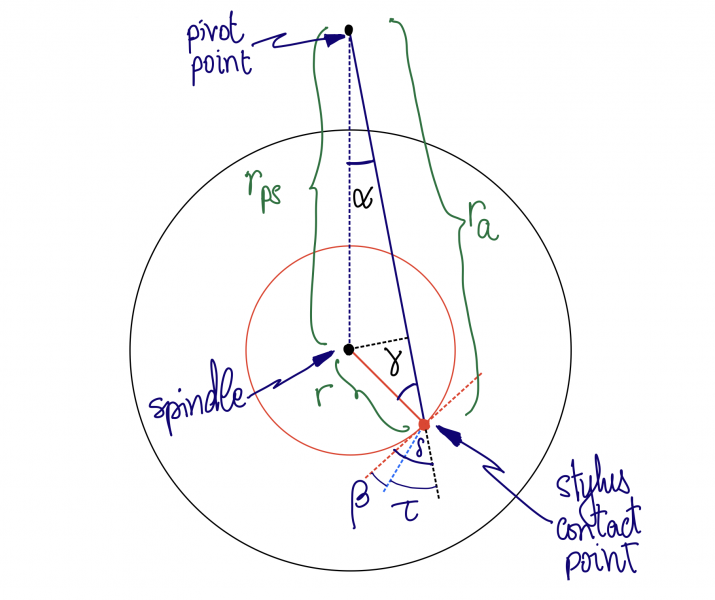

Consider this diagram:

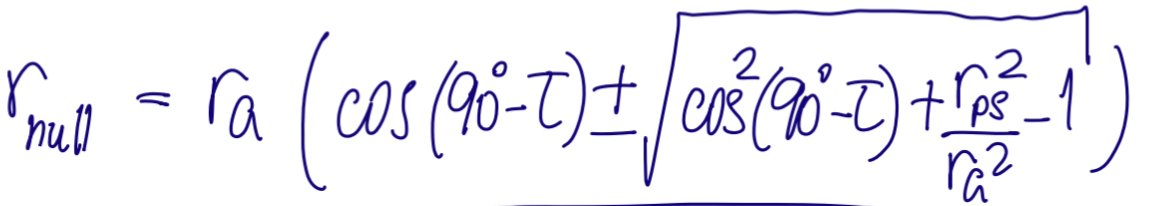

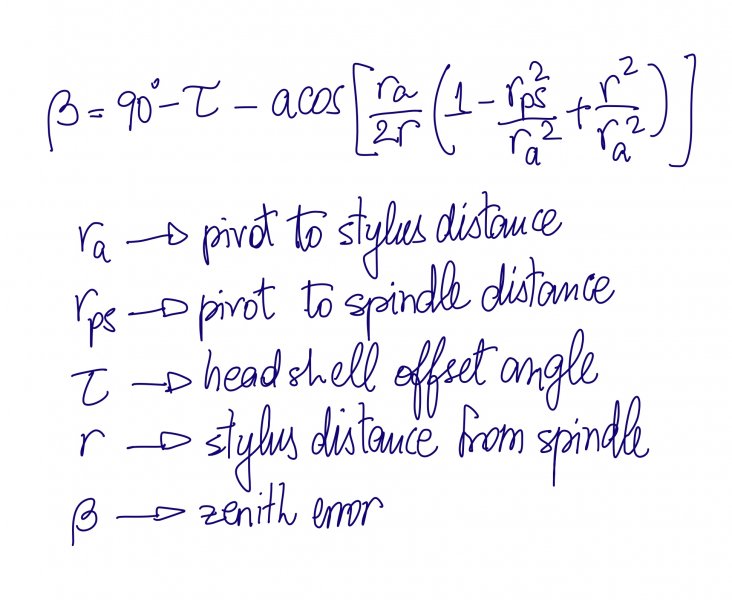

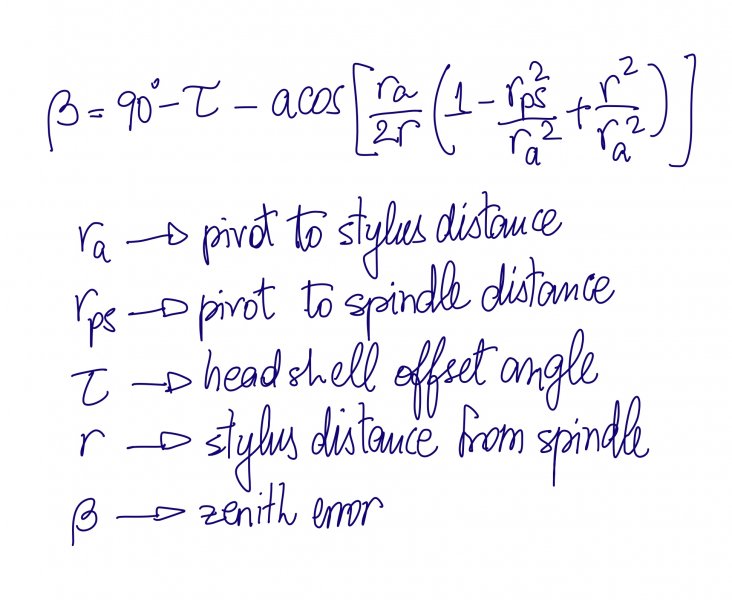

After doing the math (link below with full details) you get that:

Full derivation and more details at: https://bit.ly/zenith-math

What is interesting here is that:

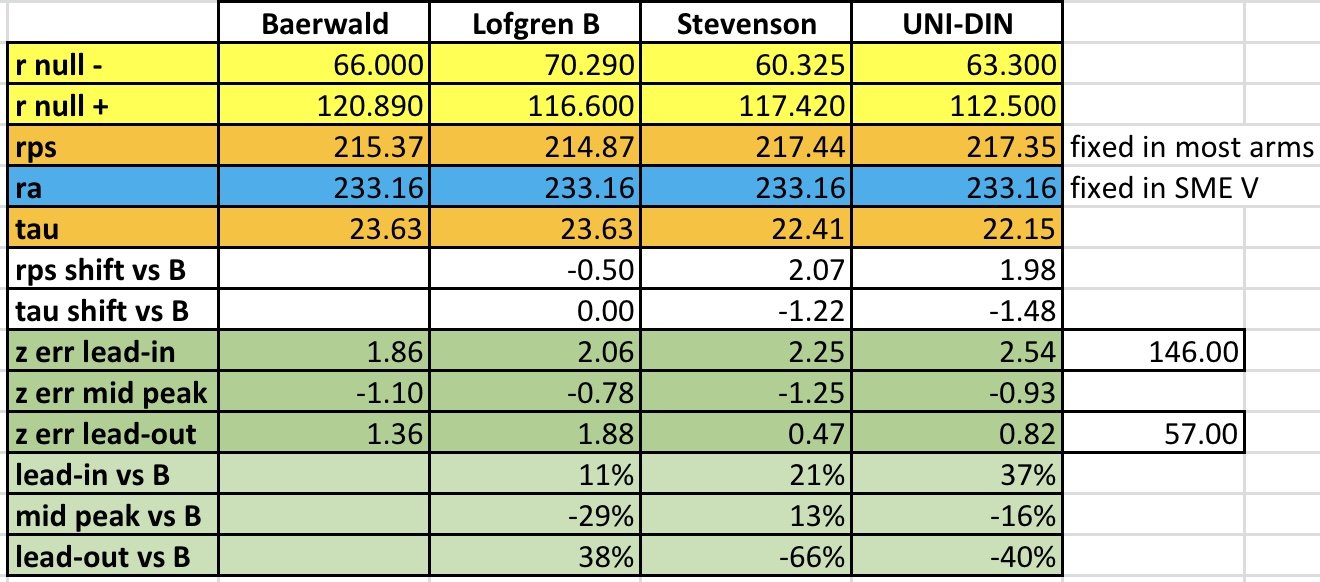

1- Given two null points (r+ and r-, in any of the conventions) determines the relationship between rps and ra as:

ra^2 - rps^2 = r+ * r-

Which means you can adjust ra (or rps in the SME V) to accomodate any convention

2- Similarly, given the null points r+, r-, and ra, the offset angle is:

tau = 90 - acos( (r+ + r-) / (2*ra) )

And what this means is:

A- Choice of null points determines ra vs rps

B- Once we get ra and rps right, aligning the null points is always possible

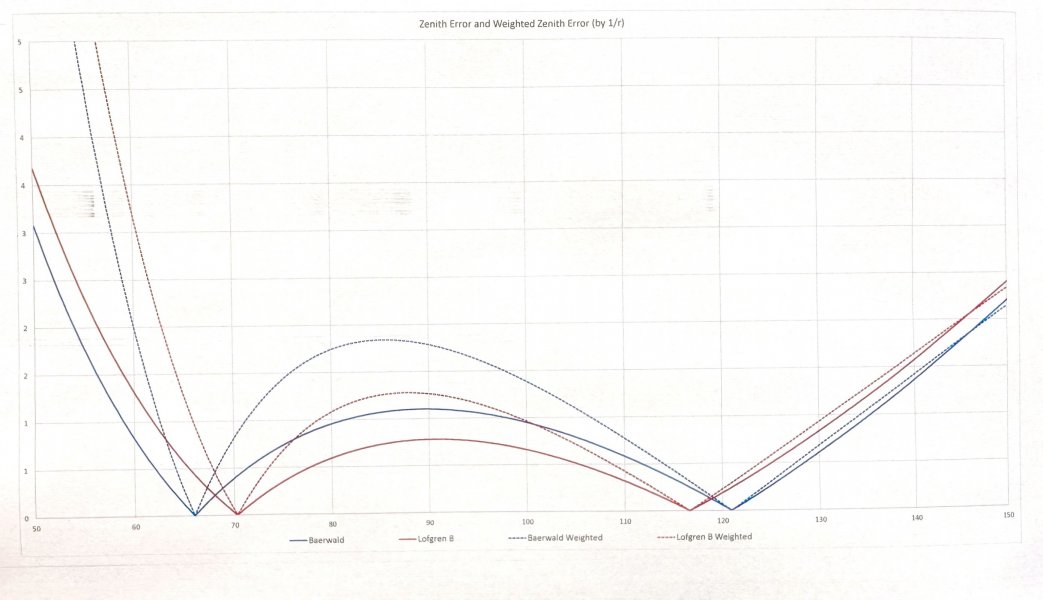

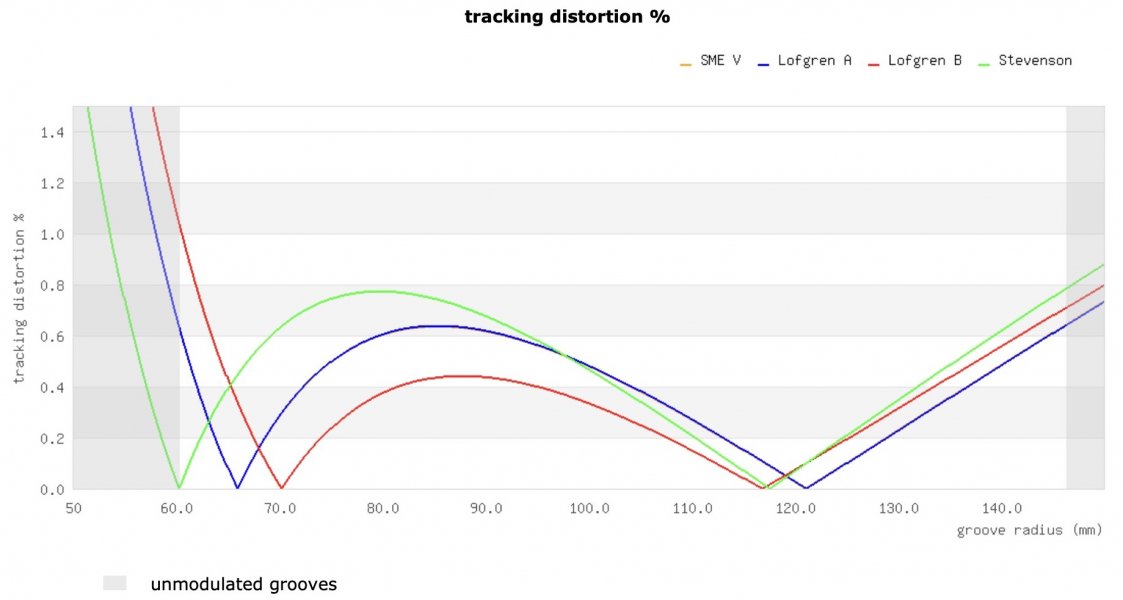

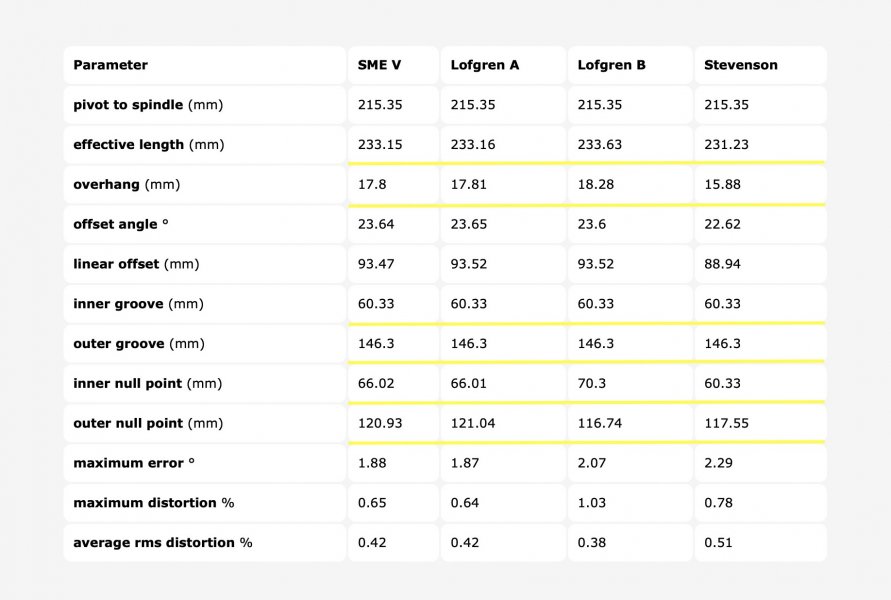

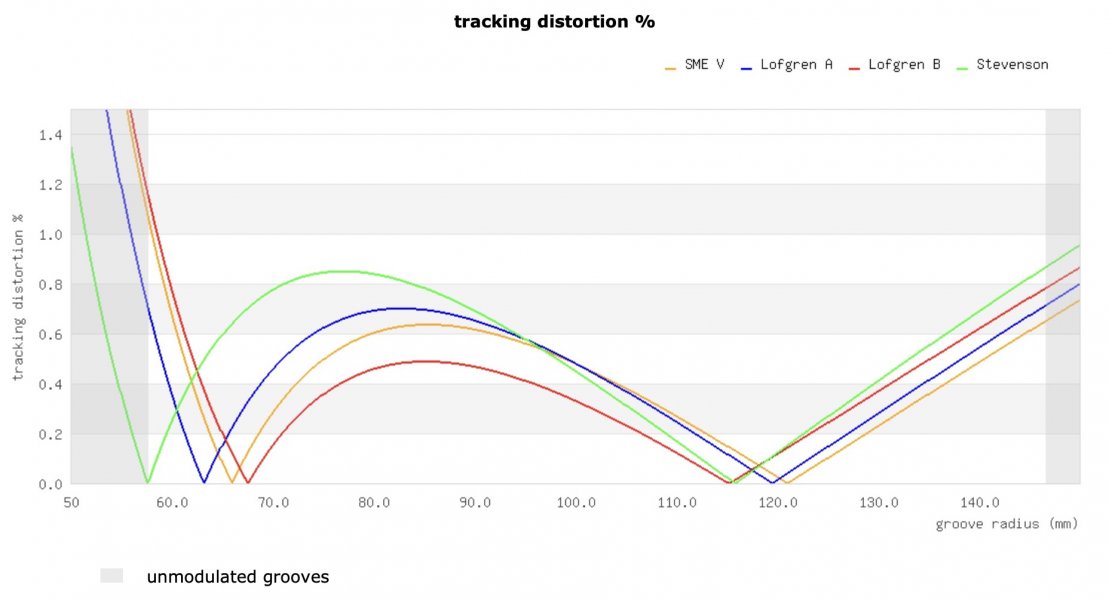

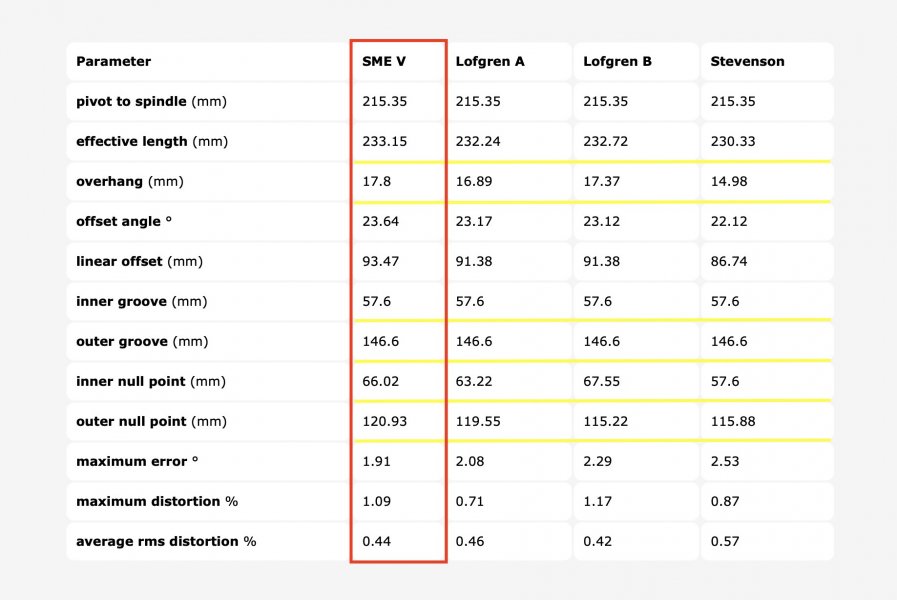

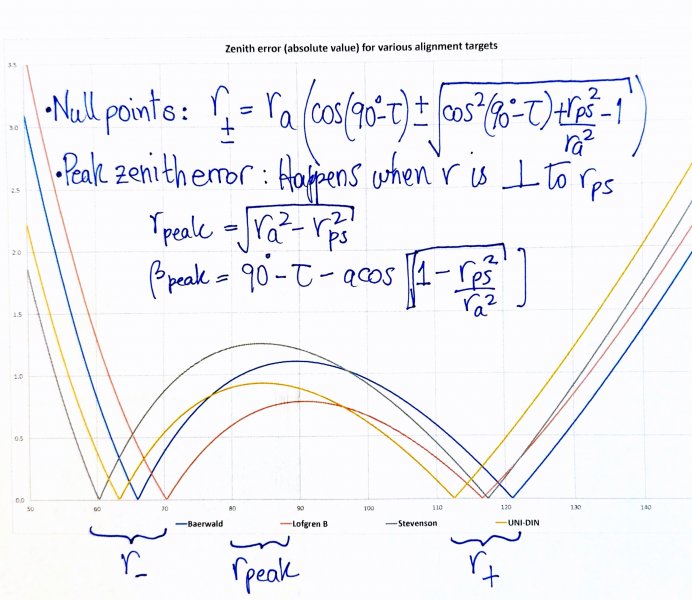

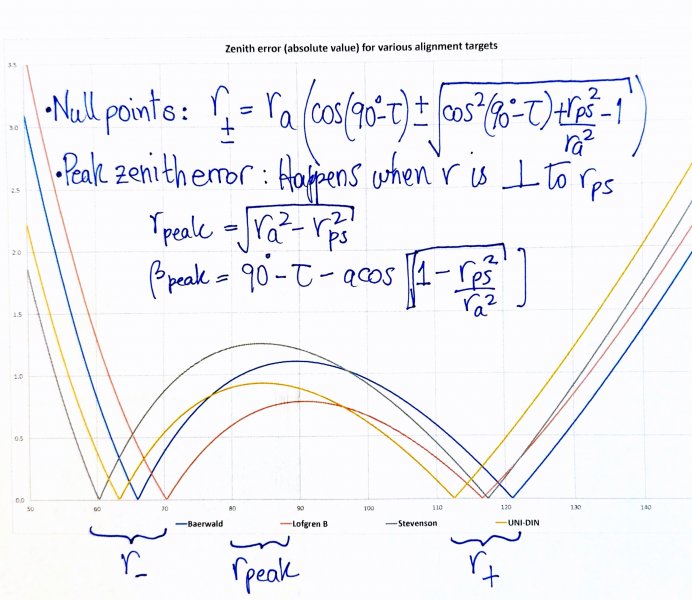

A plot of abs(beta) function for various alignment conventions:

miguelito

Consider this diagram:

After doing the math (link below with full details) you get that:

Full derivation and more details at: https://bit.ly/zenith-math

What is interesting here is that:

1- Given two null points (r+ and r-, in any of the conventions) determines the relationship between rps and ra as:

ra^2 - rps^2 = r+ * r-

Which means you can adjust ra (or rps in the SME V) to accomodate any convention

2- Similarly, given the null points r+, r-, and ra, the offset angle is:

tau = 90 - acos( (r+ + r-) / (2*ra) )

And what this means is:

A- Choice of null points determines ra vs rps

B- Once we get ra and rps right, aligning the null points is always possible

A plot of abs(beta) function for various alignment conventions:

miguelito

Last edited: