I’m been meaning to write this up for a while and now it seems like the sort of essay whose length is more suited for an assignment on “what I did on my summer vacation”.

When I built my home a few years ago, I had enough foresight to know I should provide plenty of flexibility for the power grid. 800-amp service was certainly sufficient, but I wanted to be able to look at the merits of individual AC outlet receptacles at some point and this planned for it. My Spectral RMA 400 monobloc amplifiers not only have the benefit of being able to be connected to any of 4 outlets presently (each individually on either a 30 amp or 40-amp line), but can be changed from one to another in a matter of minutes. This has helped me make some observations that I found useful and that I’d like to share.

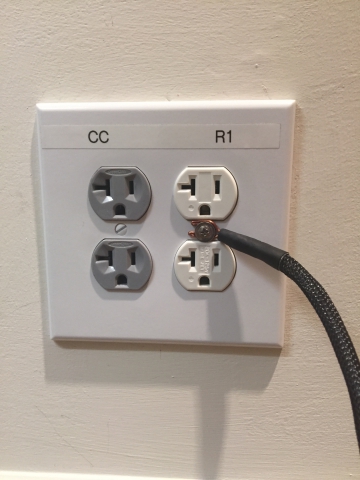

As you can see in Fig 1, connection is possible to two identical sets of quad outlets each containing an AC duplex comprising one of the following: a) Shunyata CopperCONN b) Oyaide RC-1 c) Furutech GTX-G(old) and d) Hubbell 8200. At one point, I included some other outlets into this mix including the Furutech GTX-R(hodium) but I’m afraid I am just not a fan of these rhodium outlets for reasons I’ll describe later. I would add that having such an easy way to change outlets doesn’t mean my conclusions are at all broadly relevant or even accurate, only that the changes I make by unplugging and plugging can be made relatively quickly.

One of the most interesting things I’ve learned is that although there has been plenty of discussion of the specific metals used by an AC outlet my conclusion from a lot of audio playing around (alternately can be interpreted as a possible huge waste of time by not doing something productive with one’s life) is that the metal or metals that an AC outlet contains isn’t necessarily as important as the combination of the outlet itself, and what is being plugged into it. Before going further, we need to take a brief detour in metallurgy.

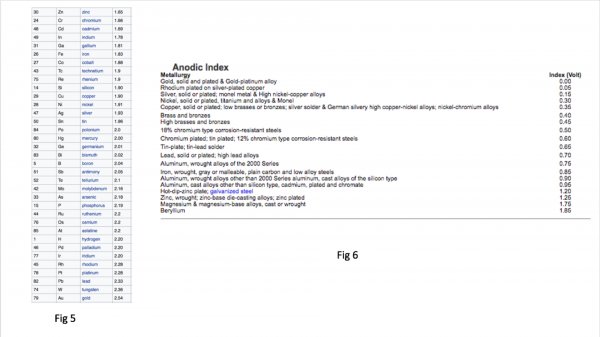

The properties of every element can be seen at a glance, in the periodic table of elements. (Fig 1) As you may remember from high school chemistry, the periodic table is a tabular arrangement of the chemical elements, ordered by their atomic number (number of*protons), electron configurations, and recurring chemical properties. The rows of the table are called periods; the columns are called groups. The periodic table can be used to derive relationships between the properties of the elements.

The periodic table provides a useful framework for analyzing chemical behavior, and is widely used in chemistry and other sciences. In the case of audio, that science that I’d like to reference is metallurgy. It should come as no surprise that what we hear in any of our systems, has in part a good deal to do with the chemical properties of the metals that are used in our system in various locations.

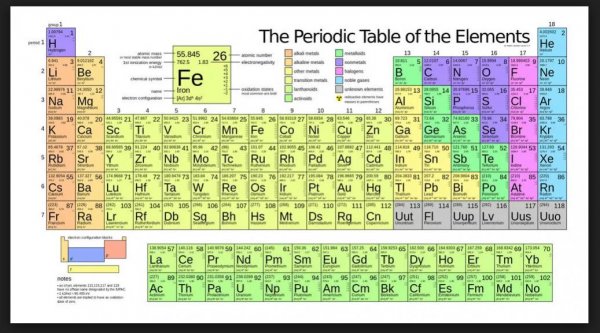

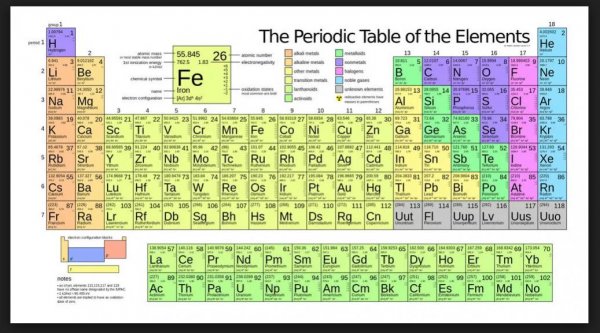

Key among these is an element’s ability to conduct electricity, and most of us are familiar with that property. It’s where silver reigns supreme. (Fig 2)

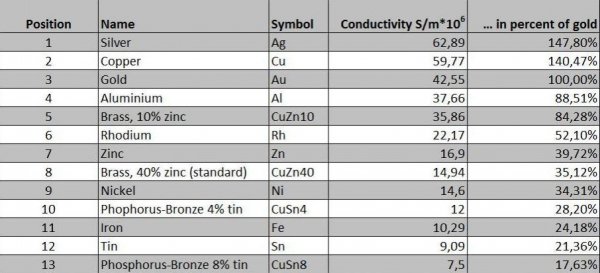

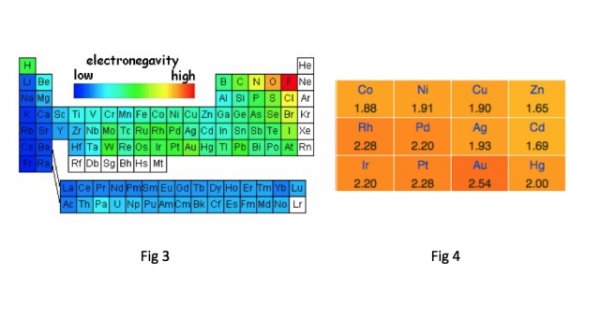

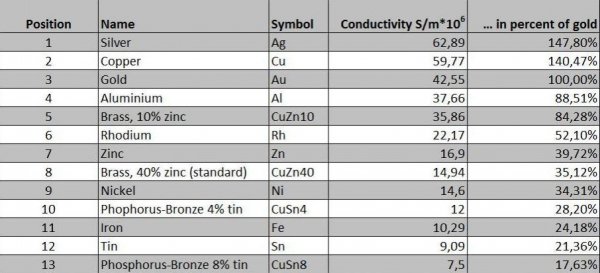

But another very important property is a metal’s electronegativity, which is a chemical property described by Linus Pauling as the power of an atom in a molecule to attract electrons to itself. Thus, when any two metals contact each other, there is will be a potential to create an electrical current if the metals have significantly different electronegativities. Another description for this is a battery effect where current will flow from the lesser to the more anodic element. (The atom having the higher electronegativity being at the negative end of the dipole.) (Fig 3)

Fig 3/4

Why this principle seems to be important in audio is because many designers try to use dissimilar metals that specifically eliminate or minimize a battery effect in their designs (i.e., cables, connectors, or AC outlets). Metals that specifically eliminate or minimize a battery effect are preferred because a battery effect implies that corrosion of the metals is occurring. This is generally agreed to have potential for sonic degradation even if in audio applications, this often occurs at miniscule levels.

Let’s a take a more specific look at the area of the periodic table where all our favorite audiophile metals lie. This group of metals lies within periods (rows) 4-7 and groups (columns) 8-11 and is part of a larger group often called the “transition” metals” (Fig 4)

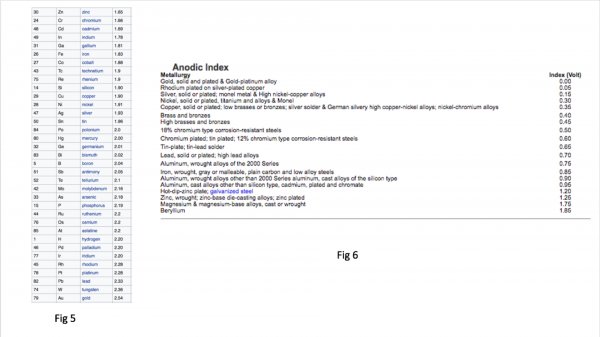

Here’s where it gets interesting. These metals can each be ranked by their relative electronegativity and in doing this, one can see easily which metals might make pairings that create of a battery effect based on the degree of similarities of their electronegativities. This is typically done using one of two scales (Allen or Pauling) but the general principles apply to both. The Pauling scale is shown here for our metals of interest, ranging from low to high electronegativity. (Fig 5)

Fig 5/6

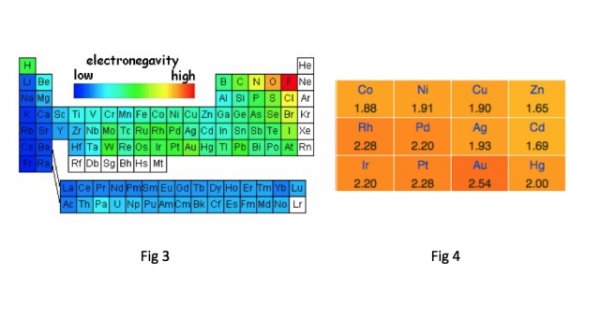

With me so far? Let's talk about corrosion. Galvanic corrosion is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. There are several ways of reducing and preventing this form of corrosion. Electrically insulate the two metals from each other. If they are not in electrical contact, no galvanic coupling will occur. This of course, is not useful for metals used in an AC receptacle! Electroplating or other plating can also help. This tends to use metals*that resist corrosion better. Chrome, nickel, silver, rhodium, platinum and gold can all be used. Now let’s look at the “anodic index” or a ranking of voltages created by a battery effect when differing metals are used in plating applications. (Fig 6) Often when design requires that dissimilar metals come in contact, their galvanic compatibility is managed by finishes and plating. The finishing and plating selected facilitate dissimilar materials from being in contact and protect the base materials from corrosion. In short, the purpose of any plating is to prevent corrosion of the underlying metals due to a battery effect. It can be seen that regarding plating, gold on gold or gold-platinum alloy has an anodic index of zero. As a rule, the higher the difference in electronegativity between two elements the greater their anodic index.

Up to now, there’s not much to discuss because this has all been rather straightforward metallurgy. But once we bring the listening experience into the picture, here’s where things get far more speculative, and likely controversial. For example, I have in general, never liked the sound of rhodium plating on copper. To me, the sound is simply not right. The timbres in the treble range just seem incorrect to my ears. Top end of violins, bells and even piano treble often don’t sound convincingly natural to me. I know rhodium plating is considered a preferred metal in many situations, and perhaps surprisingly, I would agree. But when it comes to rhodium on copper specifically, I’m just not a fan. To be honest, I never understood nor cared to understand the reasons why.

However, in looking at metal properties a bit deeper, perhaps there is some basis for my bias. Its plain to see that the electronegativites between Copper (Cu) and rhodium (Ru) are fairly discordant (1.90 and 2.28) and I think the electronegativity differences of these metals help me understand why I don’t enjoy the sonic results of this plating pairing.

But here’s a surprise. A few months ago, I acquired some Cardas Beyond Clear cables for my phono front end (Cartridge to ASR phono stage; phono stage to VL 7.5 III preamp), and much to my surprise, I thought their sound was excellent even though, wouldn’t you know it, their XLR terminations are rhodium plated! Well, holy crap, I thought, there goes my electronegativity difference theory for sonic audio effects of plated metals. But wait! As I considered this a bit more and I was dumbfounded when I discovered that Cardas is not plating rhodium on copper, but rather on silver-plated copper! And I was further blown away when I looked the anodic index of plating rhodium on silver-plated copper. It’s -0.05 volts!! The anodic index table doesn’t list the anodic index for every metal pairing possible, but holy cow, -0.05 volts is about as close to a perfect 0.00 as it gets! I have no doubt that George Cardas figured this out a long time ago as these metallurgy effects have been known for decades.

Let’s look at another example. I have been impressed with the P-004 Male and C-004 IEC AC plug terminations made by Oyaide. In fact, two of my cables (pre-amp and JL-1 crossover) use these connectors on the excellent and very affordable Audio Art 1SE power cable. After going through a heck of a lot of cable terminations of various platings, I seem to favor the Oyaides in those specific applications. Why? I honestly have no idea but they just sound beautiful to me. The highs are particularly natural and the entire cable is neutral and musical. I wonder if one of the reasons I’m impressed with these terminations is the choice of metals used? In this case, Oyaide uses beryllium copper plated with platinum plating which is then plated with palladium. This makes some sense to me as the electronegativity difference between platinum and palladium is very small (-.0.08). Therefore, I wonder if Oyaide, like Cardas, takes advantage of an intermediate third metal to minimize the anodic index of the metals used for their plating?

Although I’ve given some rationale for some sonic preferences, and while I may have a glimpse of a hypothesis that seems reasonable for putting into context some of the effects I’m hearing, these adventures are certainly incomplete at best. In fact, some findings are quite unexpected and confusing. For example, if I use a PC with Oyaide 004 terminations into an Oyaide R1 outlet, why doesn’t that pairing sound as good as the same PC run into a CopperCONN outlet? For the Oyaide pairing, I would think that since the AC plug and the AC outlet use the same plating, that a palladium to palladium contact would have negligible electronegativity differences, and should sound great. But that is not the case. A PC with 004 terminations sounds much better when plugged into the CopperCONN outlet (which means palladium is making contact with nickel). So I remain baffled. Believe me, that’s not the only thing that has me still asking many questions . However, from my experience thus far, I think some generalized concepts have emerged, at least for me.

I have spent 6 months meticulously going through listening tests and correlating the results with metallurgy observations (particularly electronegativity; i.e. anodic voltage). As I mentioned earlier, the power cord used is not the most important factor in the sound one obtains. Rather it is the specific power cord terminations combined with the outlets that receive it on both the AC and gear ends that have a great effect. One important consequence of this is that you can generally change your AC outlets easily, but you can’t change the IEC outlet on most gear. It’s just a limitation that we must accept. Fortunately, most high end uses IEC outlets of a high copper content mix (brass, bronze, phosphobronze, beryllium,) without plating.

So, to cut to the chase, my current preferences regarding AC outlets and Power cords are:

Base metals

1) copper

2) brass

3) phosphor bronze

Plating

1) none

2) nickel over copper or brass (for outlets) and palladium over platinum over copper (for cable termination)

3) rhodium over solver over copper

4) gold over copper (better for bottom end than mids/top end, which is dark sounding)

5) rhodium over copper- should be avoided completely.

My current wall outlets are Shunyata CopperCONN nickel over copper (they are not yet commercially available). Not sure why they sound so much better than anything else I've tried but they do. Caelin thinks that among other things (vice-like tightness of the plug fit) nickel plating on copper generates a nominal battery effect. This is no surprise as the electronegativity of nickel and copper is 1.91 and 1.90 respectively. Pretty damn minimal difference! Other AC receptacle manufacturers seem to agree. My understanding is that the CopperCONN AC outlets will be commercialized shortly. In the interim, the poor man's versions of the CopperCONN are the PS Audio (also nickel over copper) which sell for $50 or try the outlet that the Great Karmeli turned me on to- Hubbell 8200 series (nickel over brass) which sell for $20 and are 85+% as good as the CopperCONNs.

http://www.hubbell-wiring.com/press/catalog/a.pdf (See A3 and A54)

My wall outlets for the ASR phono and JL-1 Gothams are Hubbell 8200. I also suspect that the Tripoint folks, who make have a high copper blend AC outlet with no plating, have something that should sound pretty darned good. Most manufacturers don’t use pure copper because it’s a very malleable metal, but perhaps Tripoint has figured out a copper blend that doesn’t suffer from these ills.

My current system comprises the following AC cables/terminations.

Goldmund Studio (industrial 24v power supply), ASR Phono Stage- Moon Audio Silver Dragon Power Cord (long discontinued supposedly because it's too expensive to make!)

Meitner TX2 and DA2- Kimber PK14 power cords each going into CoppCONN AC outlets

VTL 7.5 III and JL Audio CR-1 Crossover. Audio Art 1SE Power cord with Oyaide P004 and C004 connectors each going into CopperCONN AC outlets

Spectral RS400 amps: Tara "The One" PCs. I've tried several PCs (MIT AC-3, Burmester, Audio Art 1-SE with Furutech gold or Oyaide 004 connectors, Shunyata Anaconda Zitron) but the Taras have high copper content terminations on both ends, no filters, and seem to be a good fit with the CopperCONN AC outlets

JL- Audio Gotham Subs: Moon Audio Silver Dragon Power Cord (discontinued)

Again, please don’t sling too many arrows if your sonic preferences differ from mine, especially with respect to rhodium. I get it, and in fact, I may certainly be getting it wrong. Obviously many adore the Furutech NCF series, which I have not tried but based on the GTX rhodium series, I'm not inclined to do so. I can only report what I hear and it goes without question that individual preferences may be as varied as our systems. I don't know if others have considered the specific role of electronegativity properties in metals to account for what we hear with various AC outlets and cable terminations. It’s hardly new metallurgy information but I can’t recall reading about this specifically.

I do hope that you found the discussion worth the reading time involved, and you will chime in with your own thoughts. If you have a favorite AC outlet, tell us why and please share its plating properties.

Marty

When I built my home a few years ago, I had enough foresight to know I should provide plenty of flexibility for the power grid. 800-amp service was certainly sufficient, but I wanted to be able to look at the merits of individual AC outlet receptacles at some point and this planned for it. My Spectral RMA 400 monobloc amplifiers not only have the benefit of being able to be connected to any of 4 outlets presently (each individually on either a 30 amp or 40-amp line), but can be changed from one to another in a matter of minutes. This has helped me make some observations that I found useful and that I’d like to share.

As you can see in Fig 1, connection is possible to two identical sets of quad outlets each containing an AC duplex comprising one of the following: a) Shunyata CopperCONN b) Oyaide RC-1 c) Furutech GTX-G(old) and d) Hubbell 8200. At one point, I included some other outlets into this mix including the Furutech GTX-R(hodium) but I’m afraid I am just not a fan of these rhodium outlets for reasons I’ll describe later. I would add that having such an easy way to change outlets doesn’t mean my conclusions are at all broadly relevant or even accurate, only that the changes I make by unplugging and plugging can be made relatively quickly.

One of the most interesting things I’ve learned is that although there has been plenty of discussion of the specific metals used by an AC outlet my conclusion from a lot of audio playing around (alternately can be interpreted as a possible huge waste of time by not doing something productive with one’s life) is that the metal or metals that an AC outlet contains isn’t necessarily as important as the combination of the outlet itself, and what is being plugged into it. Before going further, we need to take a brief detour in metallurgy.

The properties of every element can be seen at a glance, in the periodic table of elements. (Fig 1) As you may remember from high school chemistry, the periodic table is a tabular arrangement of the chemical elements, ordered by their atomic number (number of*protons), electron configurations, and recurring chemical properties. The rows of the table are called periods; the columns are called groups. The periodic table can be used to derive relationships between the properties of the elements.

The periodic table provides a useful framework for analyzing chemical behavior, and is widely used in chemistry and other sciences. In the case of audio, that science that I’d like to reference is metallurgy. It should come as no surprise that what we hear in any of our systems, has in part a good deal to do with the chemical properties of the metals that are used in our system in various locations.

Key among these is an element’s ability to conduct electricity, and most of us are familiar with that property. It’s where silver reigns supreme. (Fig 2)

But another very important property is a metal’s electronegativity, which is a chemical property described by Linus Pauling as the power of an atom in a molecule to attract electrons to itself. Thus, when any two metals contact each other, there is will be a potential to create an electrical current if the metals have significantly different electronegativities. Another description for this is a battery effect where current will flow from the lesser to the more anodic element. (The atom having the higher electronegativity being at the negative end of the dipole.) (Fig 3)

Fig 3/4

Why this principle seems to be important in audio is because many designers try to use dissimilar metals that specifically eliminate or minimize a battery effect in their designs (i.e., cables, connectors, or AC outlets). Metals that specifically eliminate or minimize a battery effect are preferred because a battery effect implies that corrosion of the metals is occurring. This is generally agreed to have potential for sonic degradation even if in audio applications, this often occurs at miniscule levels.

Let’s a take a more specific look at the area of the periodic table where all our favorite audiophile metals lie. This group of metals lies within periods (rows) 4-7 and groups (columns) 8-11 and is part of a larger group often called the “transition” metals” (Fig 4)

Here’s where it gets interesting. These metals can each be ranked by their relative electronegativity and in doing this, one can see easily which metals might make pairings that create of a battery effect based on the degree of similarities of their electronegativities. This is typically done using one of two scales (Allen or Pauling) but the general principles apply to both. The Pauling scale is shown here for our metals of interest, ranging from low to high electronegativity. (Fig 5)

Fig 5/6

With me so far? Let's talk about corrosion. Galvanic corrosion is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. There are several ways of reducing and preventing this form of corrosion. Electrically insulate the two metals from each other. If they are not in electrical contact, no galvanic coupling will occur. This of course, is not useful for metals used in an AC receptacle! Electroplating or other plating can also help. This tends to use metals*that resist corrosion better. Chrome, nickel, silver, rhodium, platinum and gold can all be used. Now let’s look at the “anodic index” or a ranking of voltages created by a battery effect when differing metals are used in plating applications. (Fig 6) Often when design requires that dissimilar metals come in contact, their galvanic compatibility is managed by finishes and plating. The finishing and plating selected facilitate dissimilar materials from being in contact and protect the base materials from corrosion. In short, the purpose of any plating is to prevent corrosion of the underlying metals due to a battery effect. It can be seen that regarding plating, gold on gold or gold-platinum alloy has an anodic index of zero. As a rule, the higher the difference in electronegativity between two elements the greater their anodic index.

Up to now, there’s not much to discuss because this has all been rather straightforward metallurgy. But once we bring the listening experience into the picture, here’s where things get far more speculative, and likely controversial. For example, I have in general, never liked the sound of rhodium plating on copper. To me, the sound is simply not right. The timbres in the treble range just seem incorrect to my ears. Top end of violins, bells and even piano treble often don’t sound convincingly natural to me. I know rhodium plating is considered a preferred metal in many situations, and perhaps surprisingly, I would agree. But when it comes to rhodium on copper specifically, I’m just not a fan. To be honest, I never understood nor cared to understand the reasons why.

However, in looking at metal properties a bit deeper, perhaps there is some basis for my bias. Its plain to see that the electronegativites between Copper (Cu) and rhodium (Ru) are fairly discordant (1.90 and 2.28) and I think the electronegativity differences of these metals help me understand why I don’t enjoy the sonic results of this plating pairing.

But here’s a surprise. A few months ago, I acquired some Cardas Beyond Clear cables for my phono front end (Cartridge to ASR phono stage; phono stage to VL 7.5 III preamp), and much to my surprise, I thought their sound was excellent even though, wouldn’t you know it, their XLR terminations are rhodium plated! Well, holy crap, I thought, there goes my electronegativity difference theory for sonic audio effects of plated metals. But wait! As I considered this a bit more and I was dumbfounded when I discovered that Cardas is not plating rhodium on copper, but rather on silver-plated copper! And I was further blown away when I looked the anodic index of plating rhodium on silver-plated copper. It’s -0.05 volts!! The anodic index table doesn’t list the anodic index for every metal pairing possible, but holy cow, -0.05 volts is about as close to a perfect 0.00 as it gets! I have no doubt that George Cardas figured this out a long time ago as these metallurgy effects have been known for decades.

Let’s look at another example. I have been impressed with the P-004 Male and C-004 IEC AC plug terminations made by Oyaide. In fact, two of my cables (pre-amp and JL-1 crossover) use these connectors on the excellent and very affordable Audio Art 1SE power cable. After going through a heck of a lot of cable terminations of various platings, I seem to favor the Oyaides in those specific applications. Why? I honestly have no idea but they just sound beautiful to me. The highs are particularly natural and the entire cable is neutral and musical. I wonder if one of the reasons I’m impressed with these terminations is the choice of metals used? In this case, Oyaide uses beryllium copper plated with platinum plating which is then plated with palladium. This makes some sense to me as the electronegativity difference between platinum and palladium is very small (-.0.08). Therefore, I wonder if Oyaide, like Cardas, takes advantage of an intermediate third metal to minimize the anodic index of the metals used for their plating?

Although I’ve given some rationale for some sonic preferences, and while I may have a glimpse of a hypothesis that seems reasonable for putting into context some of the effects I’m hearing, these adventures are certainly incomplete at best. In fact, some findings are quite unexpected and confusing. For example, if I use a PC with Oyaide 004 terminations into an Oyaide R1 outlet, why doesn’t that pairing sound as good as the same PC run into a CopperCONN outlet? For the Oyaide pairing, I would think that since the AC plug and the AC outlet use the same plating, that a palladium to palladium contact would have negligible electronegativity differences, and should sound great. But that is not the case. A PC with 004 terminations sounds much better when plugged into the CopperCONN outlet (which means palladium is making contact with nickel). So I remain baffled. Believe me, that’s not the only thing that has me still asking many questions . However, from my experience thus far, I think some generalized concepts have emerged, at least for me.

I have spent 6 months meticulously going through listening tests and correlating the results with metallurgy observations (particularly electronegativity; i.e. anodic voltage). As I mentioned earlier, the power cord used is not the most important factor in the sound one obtains. Rather it is the specific power cord terminations combined with the outlets that receive it on both the AC and gear ends that have a great effect. One important consequence of this is that you can generally change your AC outlets easily, but you can’t change the IEC outlet on most gear. It’s just a limitation that we must accept. Fortunately, most high end uses IEC outlets of a high copper content mix (brass, bronze, phosphobronze, beryllium,) without plating.

So, to cut to the chase, my current preferences regarding AC outlets and Power cords are:

Base metals

1) copper

2) brass

3) phosphor bronze

Plating

1) none

2) nickel over copper or brass (for outlets) and palladium over platinum over copper (for cable termination)

3) rhodium over solver over copper

4) gold over copper (better for bottom end than mids/top end, which is dark sounding)

5) rhodium over copper- should be avoided completely.

My current wall outlets are Shunyata CopperCONN nickel over copper (they are not yet commercially available). Not sure why they sound so much better than anything else I've tried but they do. Caelin thinks that among other things (vice-like tightness of the plug fit) nickel plating on copper generates a nominal battery effect. This is no surprise as the electronegativity of nickel and copper is 1.91 and 1.90 respectively. Pretty damn minimal difference! Other AC receptacle manufacturers seem to agree. My understanding is that the CopperCONN AC outlets will be commercialized shortly. In the interim, the poor man's versions of the CopperCONN are the PS Audio (also nickel over copper) which sell for $50 or try the outlet that the Great Karmeli turned me on to- Hubbell 8200 series (nickel over brass) which sell for $20 and are 85+% as good as the CopperCONNs.

http://www.hubbell-wiring.com/press/catalog/a.pdf (See A3 and A54)

My wall outlets for the ASR phono and JL-1 Gothams are Hubbell 8200. I also suspect that the Tripoint folks, who make have a high copper blend AC outlet with no plating, have something that should sound pretty darned good. Most manufacturers don’t use pure copper because it’s a very malleable metal, but perhaps Tripoint has figured out a copper blend that doesn’t suffer from these ills.

My current system comprises the following AC cables/terminations.

Goldmund Studio (industrial 24v power supply), ASR Phono Stage- Moon Audio Silver Dragon Power Cord (long discontinued supposedly because it's too expensive to make!)

Meitner TX2 and DA2- Kimber PK14 power cords each going into CoppCONN AC outlets

VTL 7.5 III and JL Audio CR-1 Crossover. Audio Art 1SE Power cord with Oyaide P004 and C004 connectors each going into CopperCONN AC outlets

Spectral RS400 amps: Tara "The One" PCs. I've tried several PCs (MIT AC-3, Burmester, Audio Art 1-SE with Furutech gold or Oyaide 004 connectors, Shunyata Anaconda Zitron) but the Taras have high copper content terminations on both ends, no filters, and seem to be a good fit with the CopperCONN AC outlets

JL- Audio Gotham Subs: Moon Audio Silver Dragon Power Cord (discontinued)

Again, please don’t sling too many arrows if your sonic preferences differ from mine, especially with respect to rhodium. I get it, and in fact, I may certainly be getting it wrong. Obviously many adore the Furutech NCF series, which I have not tried but based on the GTX rhodium series, I'm not inclined to do so. I can only report what I hear and it goes without question that individual preferences may be as varied as our systems. I don't know if others have considered the specific role of electronegativity properties in metals to account for what we hear with various AC outlets and cable terminations. It’s hardly new metallurgy information but I can’t recall reading about this specifically.

I do hope that you found the discussion worth the reading time involved, and you will chime in with your own thoughts. If you have a favorite AC outlet, tell us why and please share its plating properties.

Marty

Last edited: