I understand @peter.park.KLAUDIO point by putting fluid inside the platter. He tries to minimize cogging and smooth out speed correction because of high torque but IMHO fluid is not the best solution. IMHO a better solution is using slip rings. A couple of rings with different radiuses located inside the platter can minimize side effects of torque of motor. Each ring will be a bearing for the bigger one. It requires precise machining and a lot of testing for deciding size of the rings and number of the rings. Think it like a ball bearing with 3 or more rings but no balls.

KLaudio's new 'Magnezar' turntable

- Thread starter MikeHorns

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

In a whirlpool -because of centrifugal force- water turns at different speeds at different radiuses cause it is fluid, it is not fixed and want to move freely. Centrifugal force changes by radius. In your analogy you’re fixed cause you’re not acting like a fluid.

While platter is spinning at 33.3rpm the fluid inside will turn slower depending on it’s radius. This is also bad for stability. I see no point on putting a fluid inside a platter.

Okay -- you probably understand this better than I. The overall radius of a platter is fixed. The water at the rim of a platter is traveling at a different speed than the water closer to the center. Isn't the speed stable at each relative position? I get that it is fluid. Are you saying the water at the rim actively moves toward the center and vice versa?

Yes. Angular velocity at each radius will be different because it’s fluid, it slips depending on the viscosity.The water at the rim of a platter is traveling at a different speed than the water closer to the center.

No, not always.Isn't the speed stable at each relative position?

Not particularly in those directions but constantly circulating. Circulating speed depends on viscosity.Are you saying the water at the rim actively moves toward the center and vice versa?

Yes. Angular velocity at each radius will be different because it’s fluid, it slips depending on the viscosity.

No, not always.

Not particularly in those directions but constantly circulating. Circulating speed depends on viscosity.

Thanks for you help understanding.

sorry but angular velocity is different at different radii for a solid as well. This is why putting a heavy weight at the end of a large radius generates more momentum than one at the end of a short radius. My Yamaha GT-2000 platter is a good example of this done very well. If the fluid is pushed to the outside of the platter it will increase the inertia because now the fluid has increased the mass spinning at the edge of the platter. Is it easier to do this with just putting more metal at the edge of the platter like my Yamaha (it required it to be an oversized platter), probably not. At the speeds a turntable spins I think the water or whatever it is will quickly reach the angular speed of the platter at that distance and be quite stable as there are no sudden fluctuations in speed. If it zipped forward and backwards quickly then of course the water would have a problem not being able to keep up with those changes as it is only weakly coupled to the platter. A stable speed in one direction should not pose a problem. It is an interesting solution but nothing more.Yes. Angular velocity at each radius will be different because it’s fluid, it slips depending on the viscosity.

No, not always.

Not particularly in those directions but constantly circulating. Circulating speed depends on viscosity.

No, angular speed is constant for a solid material for example an aluminum platter on all radiuses. On the other hand linear velocity is not constant. That’s why there is less space on a record getting closer to the label. Unlike constant angular velocity based vinyl records Cd is a constant linear velocity based medium. There is no fixed speed for Cd like 33.3rpm, 45rpm etc. Probably you’re confused angular velocity with linear velocity.sorry but angular velocity is different at different radii for a solid as well.

Yes, as I said before momentum increases with radius, no problem on that. But don’t confuse fluid with solid. They act differently.This is why putting a heavy weight at the end of a large radius generates more momentum than one at the end of a short radius. My Yamaha GT-2000 platter is a good example of this done very well. If the fluid is pushed to the outside of the platter it will increase the inertia because now the fluid has increased the mass spinning at the edge of the platter.

If it would have been as you said like water acting like solid material, not slipping, there wouldn’t be washing, mixing machines based on same principle. As I said before slipping can be reduced increasing viscosity.I think the water or whatever it is will quickly reach the angular speed of the platter at that distance and be quite stable as there are no sudden fluctuations in speed.

Last edited:

In order for the fluid inside the platter to act a solid outer ring clamp, you would need a respectable space of no fluid within the sealed platter to allow all of the water to find its way to the outer perimeter of the platter from centrifugal forces as the platter spins. This all depends on the fluids viscosity, friction, density etc etc agains the centrifugal forces acting upon it.

If the platter is slightly off from being perfectly level (and yes you would be surprised how many people say their TT's are level when they are not in all horizontal planes at various angles) then some of the fluid may not find it's way to the outer perimeter of the platter if the frictional forces of the fluid are higher than the centrifugal forces acting upon it.

There has been quite a few TT's both recently and in the distant that have been designed and built that I see as being way too complicated to solve quite simple engineering issues or concerns that a TT has to perform to and against to obtain an excellent performance of obtaining as much information from the grooves as possible.

For me, I just want a TT that spins at the correct speed constantly, is pretty immune to external air and structural vibrations and that are not passing to the stylus to pick up, has no internal vibrations passing to the stylus to pick up, and has a stable platform to mount the tonearm that should also be immune to internal and external vibrations etc.

If the platter is slightly off from being perfectly level (and yes you would be surprised how many people say their TT's are level when they are not in all horizontal planes at various angles) then some of the fluid may not find it's way to the outer perimeter of the platter if the frictional forces of the fluid are higher than the centrifugal forces acting upon it.

There has been quite a few TT's both recently and in the distant that have been designed and built that I see as being way too complicated to solve quite simple engineering issues or concerns that a TT has to perform to and against to obtain an excellent performance of obtaining as much information from the grooves as possible.

For me, I just want a TT that spins at the correct speed constantly, is pretty immune to external air and structural vibrations and that are not passing to the stylus to pick up, has no internal vibrations passing to the stylus to pick up, and has a stable platform to mount the tonearm that should also be immune to internal and external vibrations etc.

Magnezar incorperates a phase-locked loop (PLL) system, which continuously checks the speed every millisecond. The racking result its displayed on our turntable, ensuring precise speed maintenance.Peter, Could you talk a little bit about how speed is maintained? Is it periodically checked and adjusted, or do you rely on the higher mass platter to maintain momentum, or some combination?

Attachments

Magnezar incorperates a phase-locked loop (PLL) system, which continuously checks the speed every millisecond. The racking result its displayed on our turntable, ensuring precise speed maintenance.

Thank you Peter. Is the platter speed user adjustable? I think your platter is fairly heavy for a direct drive design. Is one of the reasons speed stability or consistency? Could you talk a little bit about platter mass with a direct drive design?

The platter speed is fixed, and you can choose between 33, 45, or 78 rpm. A heavier platter offers improved stability, consistency, and torque, resulting in a more stable and powerful sound. However, many companies face difficulties in increasing platter weight, and even if they manage to do so, the bearings often wear out quickly and fail. This is because finding thrust bearings capable of supporting the rotation of a heavy platter for extended periods is challenging.Thank you Peter. Is the platter speed user adjustable? I think your platter is fairly heavy for a direct drive design. Is one of the reasons speed stability or consistency? Could you talk a little bit about platter mass with a direct drive design?

Magnezar has addressed this issue by implementing full magnetic levitation technology. The spindle shaft is designed to rotate without the need for mechanical thrust bearings, ensuring the most stable and thrilling playback experience possible. Additionally, this design allows the turntable to be used for extended periods without the risk of mechanical wear.

The platter speed is fixed, and you can choose between 33, 45, or 78 rpm. A heavier platter offers improved stability, consistency, and torque, resulting in a more stable and powerful sound. However, many companies face difficulties in increasing platter weight, and even if they manage to do so, the bearings often wear out quickly and fail. This is because finding thrust bearings capable of supporting the rotation of a heavy platter for extended periods is challenging.

Magnezar has addressed this issue by implementing full magnetic levitation technology. The spindle shaft is designed to rotate without the need for mechanical thrust bearings, ensuring the most stable and thrilling playback experience possible. Additionally, this design allows the turntable to be used for extended periods without the risk of mechanical wear.

Thank you for those details. My turntable has a 150 lbs platter supported by a cushion of air. It takes 35 minutes to come to rest from 33.33 RPM when detached from the motor thread. I agree with your description of a more stable and powerful sound, but also with greater nuance and dynamics. I leave my platter spinning for hours every day without any concern for bearing wear.

Considering that these turntables seem to be of recent manufacture, By running the platter unnecessarily . how do you know this to be the situation in the longer term ?I leave my platter spinning for hours every day without any concern for bearing wear.

Considering that these turntables seem to be of recent manufacture, By running the platter unnecessarily . how do you know this to be the situation in the longer term ?

When the turntable was being developed it was on continuously for over a month and then the bearing was checked. There was zero damage. It is a similar design to the original American Sound turntable from the 1970s and I had one of those for a month and I inspected the bearing when I assembled it. There is basically no contact. It is almost a friction free design. My 150 lbs platter takes 35 minutes to come to rest from free spinning at 33.33 RPM.

Hi Peter, do you know whether the bearing in your turntable is the full air bearing type (i.e. air bearing for both the vertical and horizontal plane), or only have air cushion for the vertical plane, like the ones in the Micro turntables? Thanks

Hello thekong, The bearing is different from the one in my old micro Seki SX 8000 II. There was a discussion about whether or not it is actually an air bearing in a different thread here on WBF.Hi Peter, do you know whether the bearing in your turntable is the full air bearing type (i.e. air bearing for both the vertical and horizontal plane), or only have air cushion for the vertical plane, like the ones in the Micro turntables? Thanks

i’m sorry for the diversion away from the new KL audio turntable. I’ll refrain from discussing the turntable anymore on this thread.

Last edited:

Is there any more news about this new Magnezar turntable? Are there reports from users?

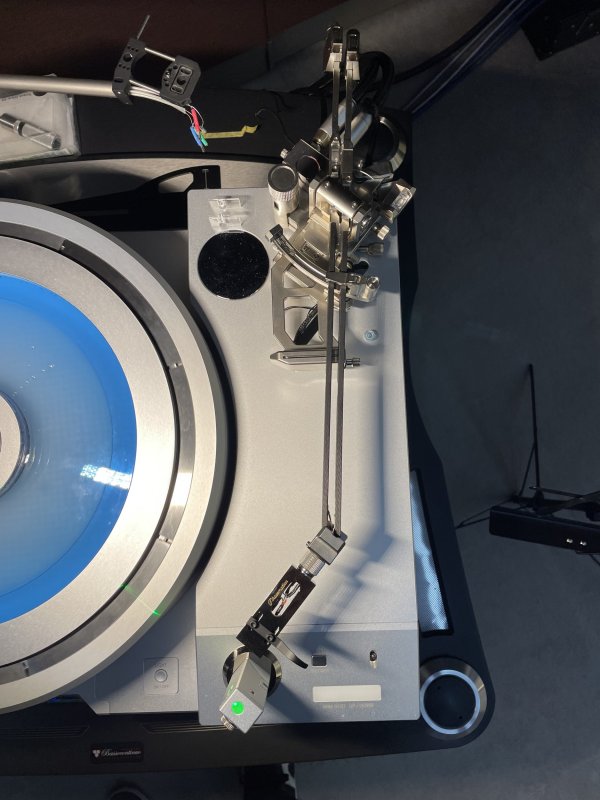

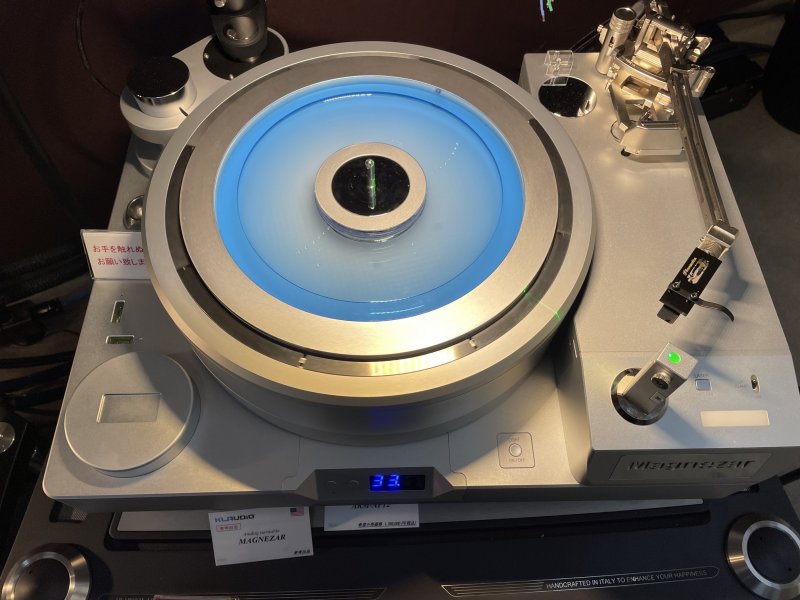

Here is a couple of pictures of Magnezar in action. I have questions in my mind about why there is liquid inside the platter and tonearm’s design but the sound in this room was quite good. I really liked it.Is there any more news about this new Magnezar turntable? Are there reports from users?

Here are some videos of it while playing:

https://drive.google.com/file/d/16tUBT3-9k9l672kGqGoAAYCECQXTd9aO/view?usp=drivesdk

https://drive.google.com/file/d/16jzt9Mbt7yYLJ5-VtWcjEkg04TcVdczQ/view?usp=drivesdk

Hello,Here is a couple of pictures of Magnezar in action. I have questions in my mind about why there is liquid inside the platter and tonearm’s design but the sound in this room was quite good. I really liked it.

View attachment 121819 View attachment 121820

Here are some videos of it while playing:

https://drive.google.com/file/d/16tUBT3-9k9l672kGqGoAAYCECQXTd9aO/view?usp=drivesdk

https://drive.google.com/file/d/16jzt9Mbt7yYLJ5-VtWcjEkg04TcVdczQ/view?usp=drivesdk

Thank you for your positive feedback. May we have your permission to share your video on our social media platforms?

Ok.May we have your permission to share your video on our social media platforms?

Similar threads

Members online

- dmtfx

- Bonesy Jonesy

- jaycoh47

- magiccow

- SOS

- skids929

- John T

- mantis007

- andromedaaudio

- Geoffkait

- dimitrisx

- Ron Resnick

- FDPDK

- kimurastanley

- XCop5089

- Another Johnson

- cmchan

- carolus

- Barry823

- studio44

- Tesuka

- bonzo75

- the sound of Tao

- Mamon

- olivier

- Stef

- Król_Artur

- kodomo

- fbs

- kyoya78

- lamechops

- ecwl

- JackJohnson316

- dminches

- Juiced

- Audiocrack

- horn150

- Lynnot

- Johan K

- cykin

- Runing_man

- Zero000

- MusicFellow

- agencal

- shawnf

- BruceD

- hesavary

- Young Skywalker

Total: 1,162 (members: 56, guests: 1,106)

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Co-Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |