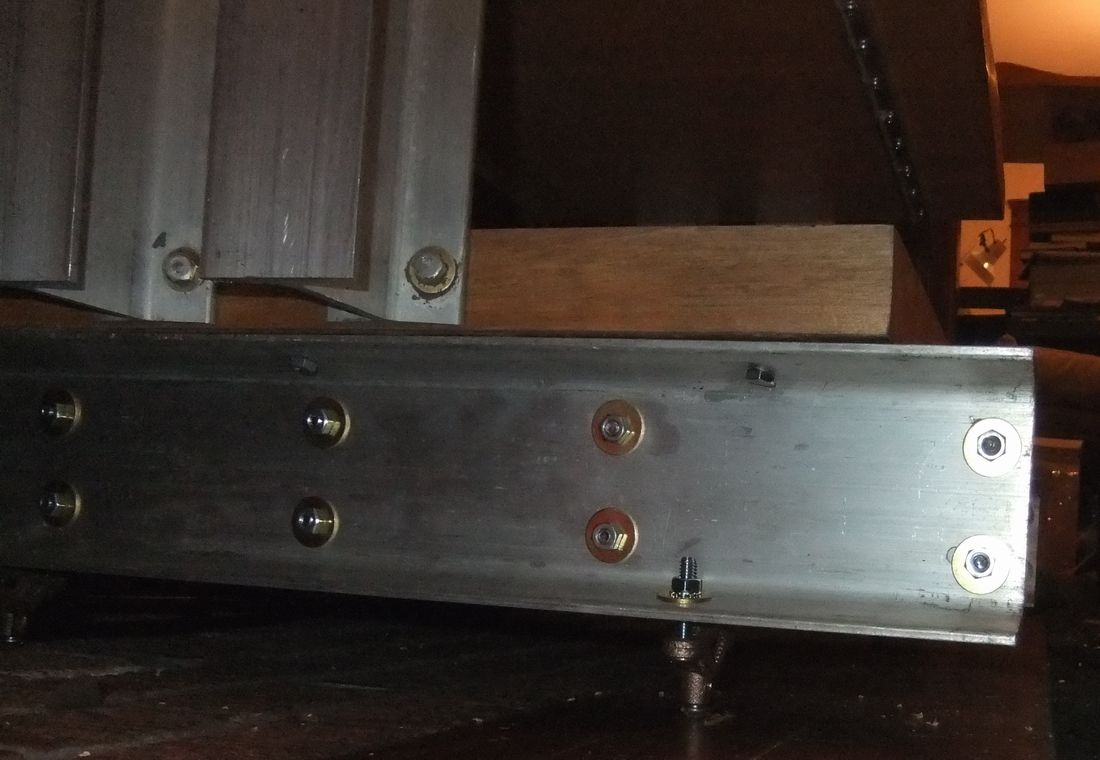

I have most of my supplies together, some discarded and weathered maple butcher block (20" x 24" x 1-3/4"), some scrap yard 4" deep C-channels (alum), and today picked up a 3" mini I-beam (alum).

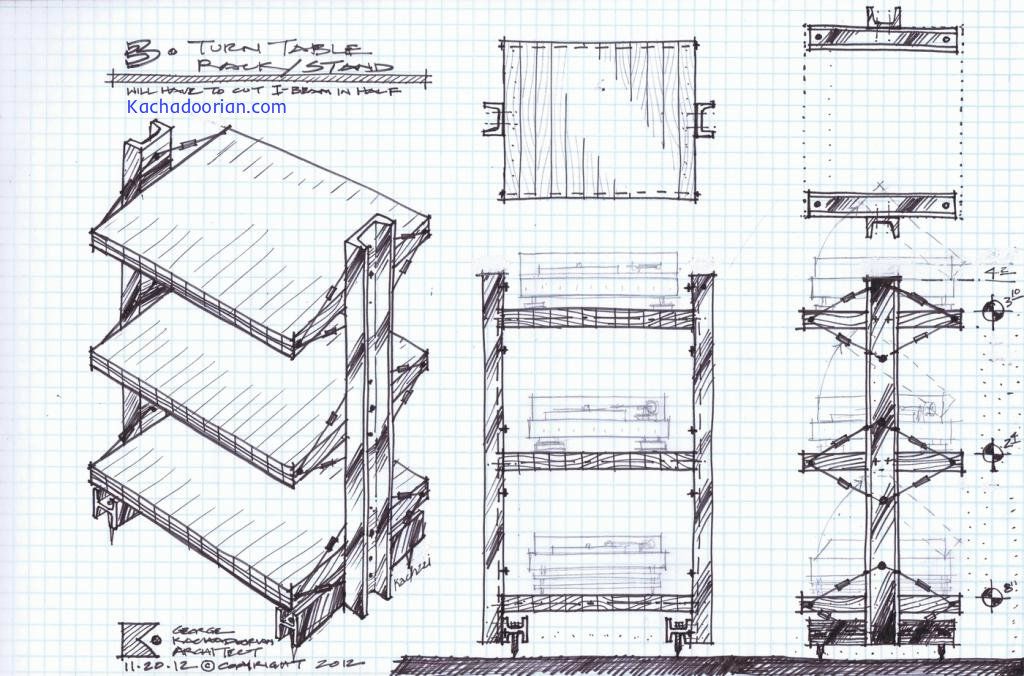

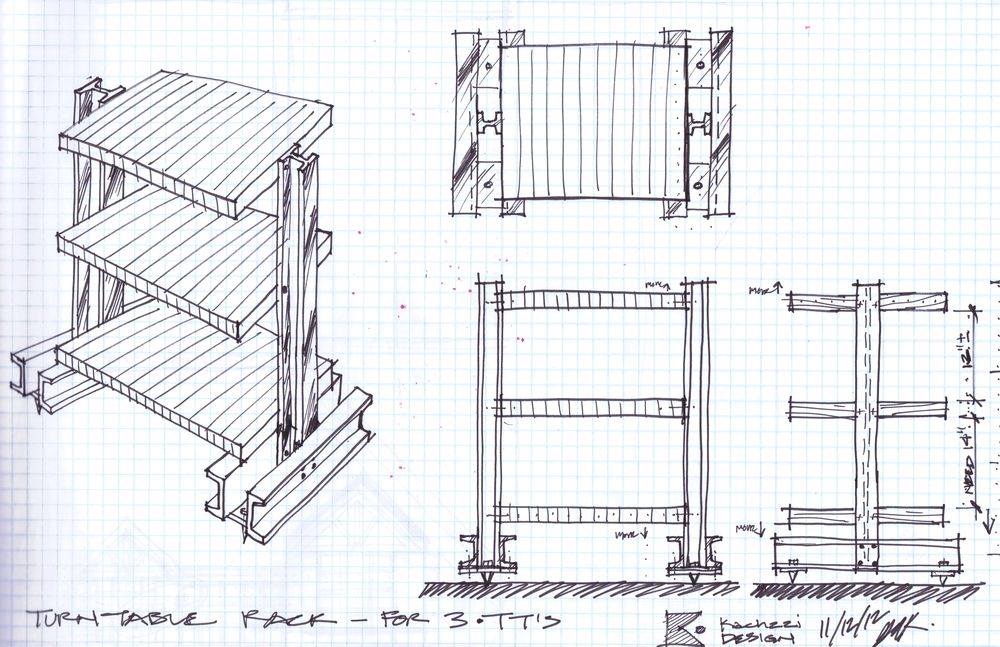

Here is what I think I'll be putting together:

http://s184.beta.photobucket.com/user/kach22i/library/DIY Audio Rack 2012

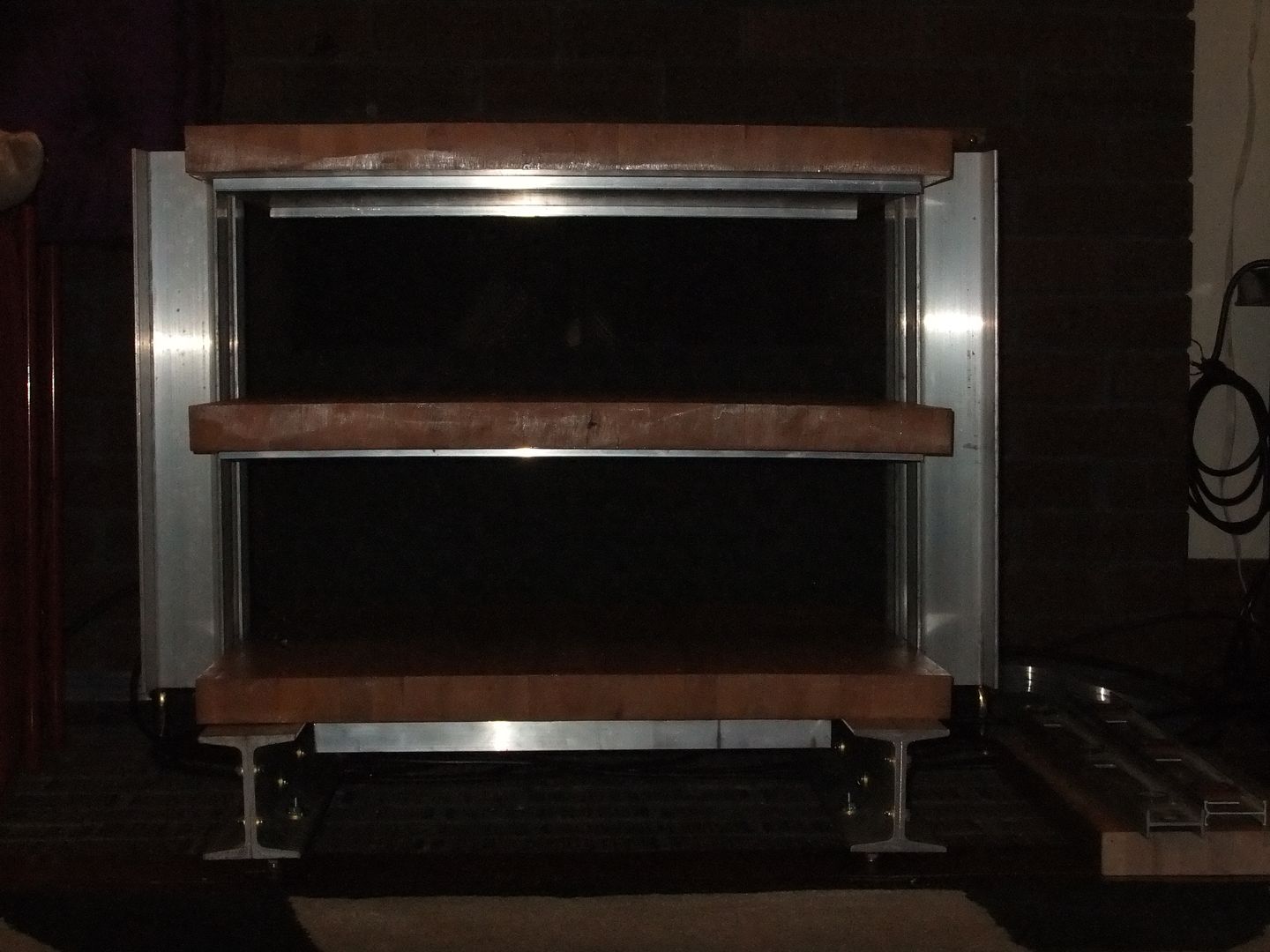

Here are the raw supplies which need sanding, finishing and drill holes.

http://s184.beta.photobucket.com/user/kach22i/library/DIY Audio Rack 2012

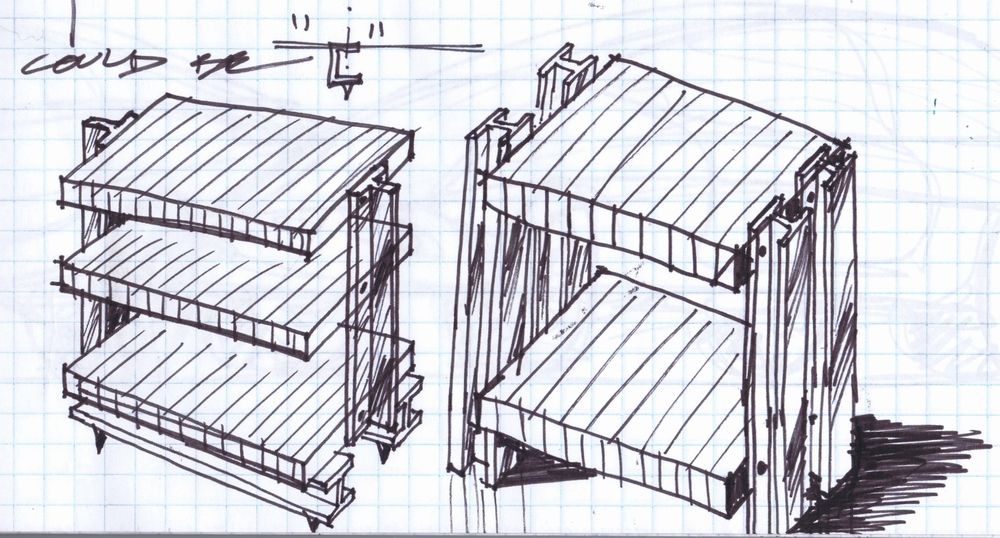

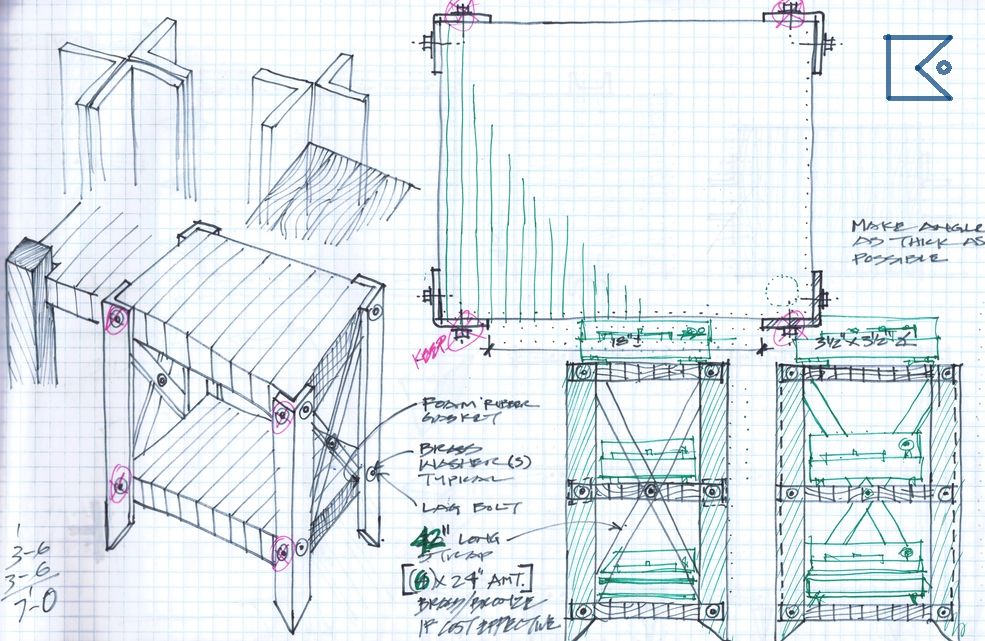

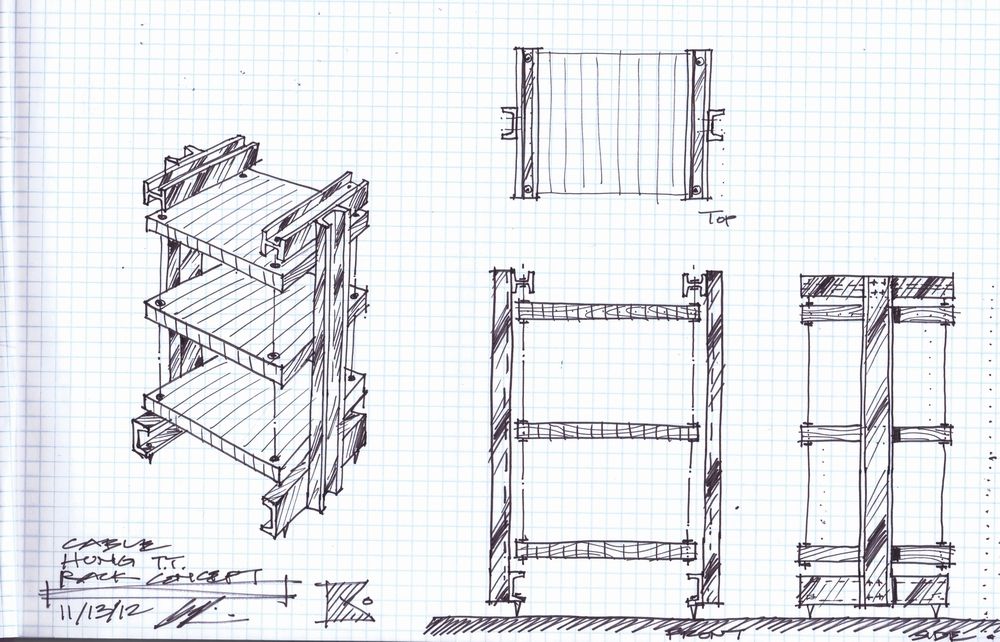

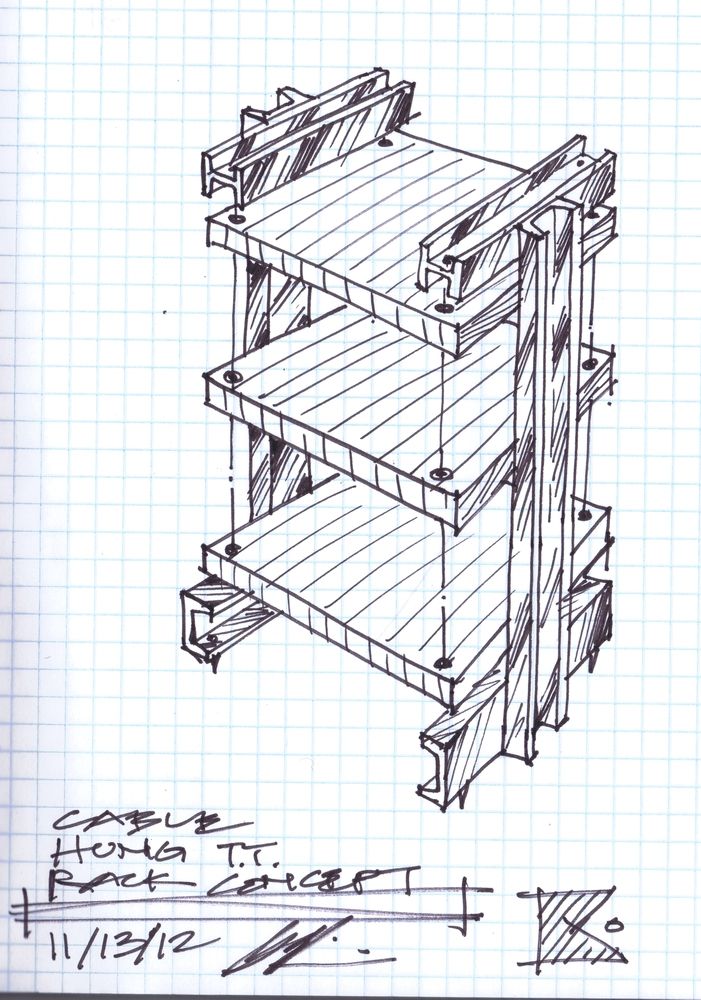

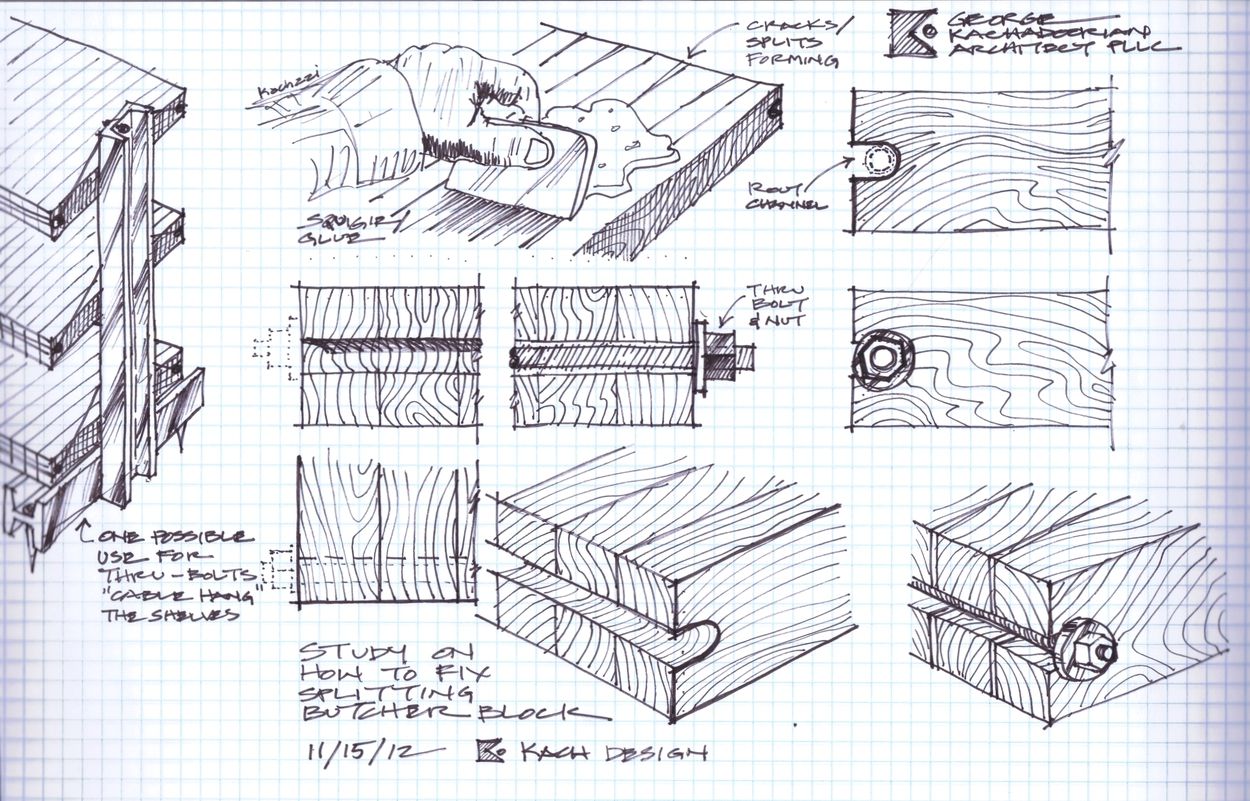

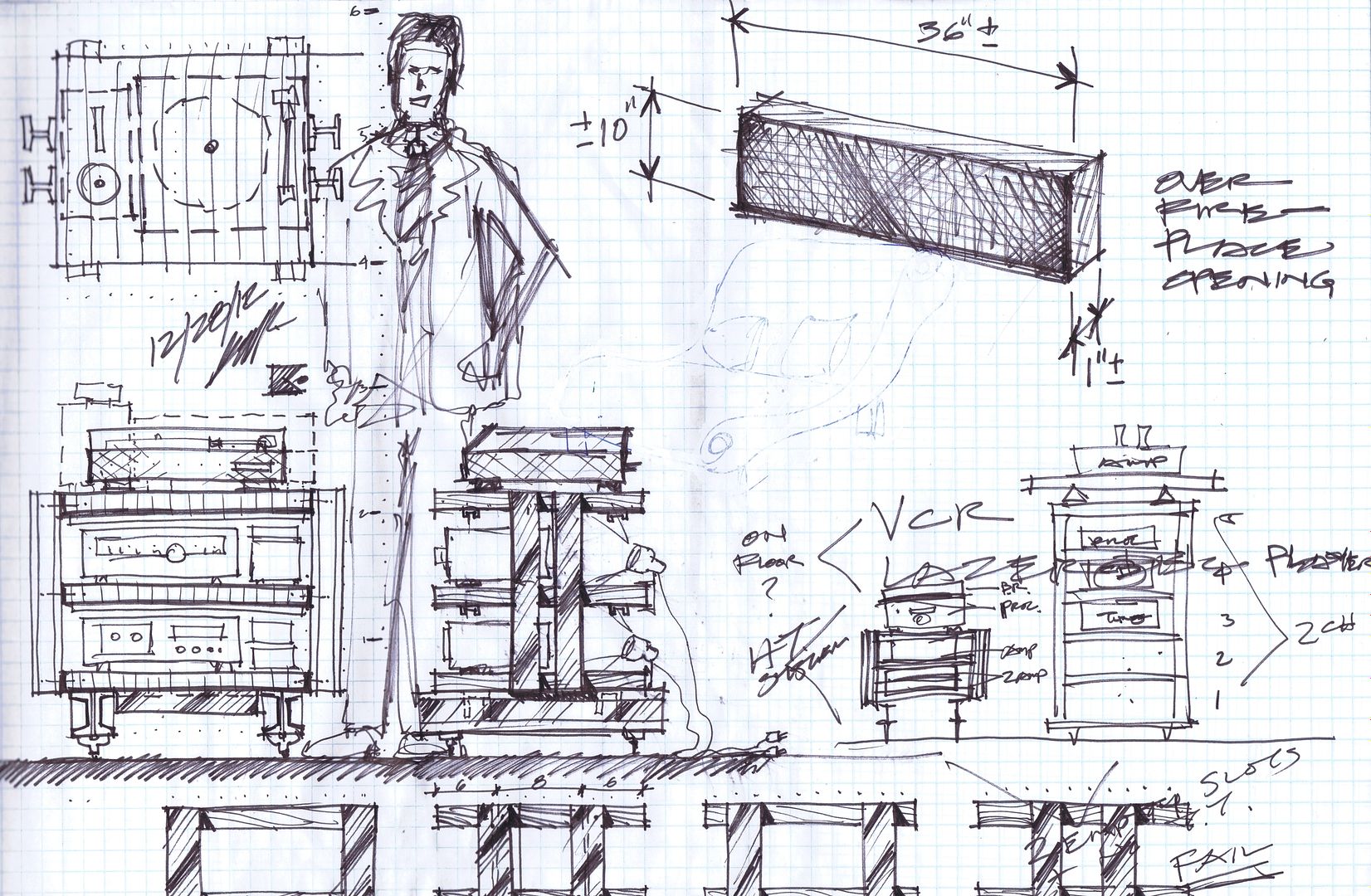

Some earlier design sketches considering other layouts and material usage (see link below).

http://s184.beta.photobucket.com/user/kach22i/library/DIY Audio Rack 2012

Any thoughts before I commit would be nice, there is still time for me to change my mind.

This will be a turntable rack for three turntables I have in my possession. I want to do a turntable comparison.

One belt driven TT I've modified, another is a direct drive which I have yet to hear, and yet another DD needs a little maintenance to get up and running such as a belt for it's tangential tonearm.

Here is what I think I'll be putting together:

http://s184.beta.photobucket.com/user/kach22i/library/DIY Audio Rack 2012

Here are the raw supplies which need sanding, finishing and drill holes.

http://s184.beta.photobucket.com/user/kach22i/library/DIY Audio Rack 2012

Some earlier design sketches considering other layouts and material usage (see link below).

http://s184.beta.photobucket.com/user/kach22i/library/DIY Audio Rack 2012

Any thoughts before I commit would be nice, there is still time for me to change my mind.

This will be a turntable rack for three turntables I have in my possession. I want to do a turntable comparison.

One belt driven TT I've modified, another is a direct drive which I have yet to hear, and yet another DD needs a little maintenance to get up and running such as a belt for it's tangential tonearm.