Spectral DMC-30 SV

- Thread starter ack

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Regarding Pass again, here's more on his relationship with SemiSouth in this bulletin http://www.semiconductor-today.com/news_items/2011/JULY/SEMISOUTH_300711.html - this time pertaining to the same silicon carbide SJEP120R family, which his SIT is based on according to the last quote in post #40, though here there is no real claim of anything custom to Pass, but I think his involvement is obvious - and more claims of no thermal tails in those devices:

and regarding the audibility of these distortions (which I think are quite audible):

extremely fast switching with no ‘tail’ current at up to a maximum operating temperature of 150ºC

and regarding the audibility of these distortions (which I think are quite audible):

...comments Nelson Pass, founder of audio amplifier manufacturer Nelson Pass Inc. “With the new SiC power JFETs from SemiSouth, this potential has been realized in reliable linear power amplifiers. In push–pull topologies, they exhibit a 50–70% improvement in distortion

Last edited:

You can only install the new SHHA3 modules - I would consider that less than half an upgrade

Do you mean that it's better to buy a new 30SV than upgrade the 30SS? I think the new SHHA3 modules will cost aprox. $ 4000 or € 4000; a new 30SV € 23000.

Do you mean that it's better to buy a new 30SV than upgrade the 30SS? I think the new SHHA3 modules will cost aprox. $ 4000 or € 4000; a new 30SV € 23000.

It's better to buy the 30SV, soundwise. Cost factoring in, I can't make that argument... Keep in mind though that the reason I re-bought a new 30SS S2 last year, replacing an original S2 version, is that the sound was significantly better, almost an "S3" revision. Yet, there were no easily discernible board differences, and I was told "there may be changes that you can't see". The point being that there may be other changes in the 30SV beyond what's discussed in this thread or the bulletins. In other words, you should probably expect to get what you pay for.

ack,

SemiSouth is long gone. The link you posted is from 2011 and the "made for audio" claim was an effort to keep the company alive by covering applications the SiC technology was never meant for. Try the company website and you'll find a weight loss company now. SiC, as well as GaN, are made for switching application (my field of expertise, 20 years now). You can search for posts from Dr. Mazzola on DIYaudio.com (nickname semisouthfan, I believe) for the whole story. He was one of the founders of the company.

To reiterate my point: investments in new semiconductors are for companies the size of Apple or Cisco or for emerging markets like Hybrid Electric Vehicles (SiC are a good match there) or for commodities like air conditioners and TV sets. Audio is, unfortunately, a legacy market nowadays. Designing discrete circuits for audio is an even smaller niche (but the one I love).

SemiSouth is long gone. The link you posted is from 2011 and the "made for audio" claim was an effort to keep the company alive by covering applications the SiC technology was never meant for. Try the company website and you'll find a weight loss company now. SiC, as well as GaN, are made for switching application (my field of expertise, 20 years now). You can search for posts from Dr. Mazzola on DIYaudio.com (nickname semisouthfan, I believe) for the whole story. He was one of the founders of the company.

To reiterate my point: investments in new semiconductors are for companies the size of Apple or Cisco or for emerging markets like Hybrid Electric Vehicles (SiC are a good match there) or for commodities like air conditioners and TV sets. Audio is, unfortunately, a legacy market nowadays. Designing discrete circuits for audio is an even smaller niche (but the one I love).

I think it's irrelevant that SemiSouth has gone south. The point and the reality is that Pass is documented to have worked with them (only 4 year ago) to make custom devices, and in fact, these devices have now made it into their main line products. From the same 6moons link, you will see the following quote from Pass:

I believe these devices are now in the Xs line as well, which is what I think the last underlined sentence refers to. I see no evidence that Spectral did not or cannot design and make (in partnership with others) their own custom semiconductors, if Pass can and did; do you? It feels like you think the landscape has changed dramatically since 2011... If the "whole story" is different than what Pass posts online, then a short summary from Dr. Mazzola's posts would be nice to see here; are Pass's devices also allegedly "re-badged"?

"There's more of this sort of thing in the works. With the XP30 preamp Wayne catered to a couple requests - dual sets of outputs independently adjustable for biamping, much lower output impedance and much higher gain options. The latter two make it an excellent front end for an amplifier, providing all I need for various follower output stages. Now I can just cobble them together and listen apples to apples. It's very interesting and illuminating to isolate the specifics of different devices, topologies and so on and trying to correlate them to the subjective side of things. So far there have been a few surprises and I'm hoping there will be more but it's terribly complicated.

Far more probable is that you will see some of these things embedded in the next generation of Pass Labs. When they heard what you heard, my partners acquired a particular gleam in their eyes." - np

I believe these devices are now in the Xs line as well, which is what I think the last underlined sentence refers to. I see no evidence that Spectral did not or cannot design and make (in partnership with others) their own custom semiconductors, if Pass can and did; do you? It feels like you think the landscape has changed dramatically since 2011... If the "whole story" is different than what Pass posts online, then a short summary from Dr. Mazzola's posts would be nice to see here; are Pass's devices also allegedly "re-badged"?

ack,

I wish I had more time to elaborate but I'm leaving for my summer holidays so please don't think I'm being rude if I tend to summarize things.

SemiSouth going south is not irrelevant. You need to know the full story to understand what happened and the nature of semiconductor business. Interest in SiC devices started many years ago mostly because of their temperature performance. SiC works at higher temperatures than silicon. This is extremely valuable in military applications. Another valuable feature of SiC is their high frequency performance. Very good for things like switch mode power supplies and radar amplifiers. SemiSouth was a pioneer in that area when the market was focusing on those "high end" applications. I don't know whether they where founded by taxpayers or what, but in any case their business model did not succeeded in turning from a vertical market (MIL) to an horizontal market (CE). The Pass liaison was a tentative in exploring yet another niche before eventually folding down. The six digit sum that NP mentions is pocket change for a mainstream semiconductor company and not enough to keep alive a boutique company, so to speak. Mass adoption of SiC and eGaN is happening now, expect big things in the next two or three years. SiC will replace IGBTs in PFC power supplies. Do you remember Pass using IGBTs? (hint: Forte line, IGBTs where Toshibas actually made for audio, long gone and with a very short life on the market. Guess why?). Going back to SiC and new semis in general, companies like Cisco don't buy semiconductors that are not fully qualified for mass production, available from multiple sources and at the right price. Companies like Pass Labs and Spectral need exotic parts to differentiate from competitors. The SIT1 is a standard part from the SemiSouth line that was selected for parameters valuable for linear applications. It is NOT a custom part made to specs. Unless you are IBM or Intel, you don't develop new semiconductor processes or devices. You buy what is available. Customization is usually limited to package and parametric selection. This is true, in many cases, even for military. Most military programs use what is commonly available. Some strategic military programs can afford huge budgets and new devices. For instance, the Apollo program was the very first "mainstream" application of solid state devices, BJTs and logic gates packaged in IC style SMD packages. Think it through, this is the way new technologies evolve. Like I said, audio is a legacy industry and it uses whatever is left from mainstream applications. In the 70s parts similar to the SIT1 where developed by companies like Sony and Yamaha. Nowadays, no semiconductor company is willing to develop parts specifically made for audio. Not enough business. The only company that somewhat differ from this rule is probably That Corporation.

I'm somewhat disappointed by the latest "upgrade" to the SHHA because it seems to me that what actually happened is Spectral buying a six digit sum of NPD5566 before they disappeared (it is called Last Time Buy in the industry), used that stash until it was depleted and then replaced the part with its modern equivalent. Nothing wrong with this. It is common practice in manufacturing. But I'm still disappointed by the fact that a superior part, the 2SK389 and then the LSK389, has been available for such a long time before it actually made it to the SHHA. So, in the end, what is OK for manufacturing is not for R&D. If a new part can give you an edge, why not using it (in the boutique industry that high end audio is).

This is not to say that the adoption of a new part and the redesign of the circuit to take full advantage of it (elimination of thermal tails) is not relevant. I'm quite sure the DMC 30SV is a great piece of engineering. I was only expecting something more.

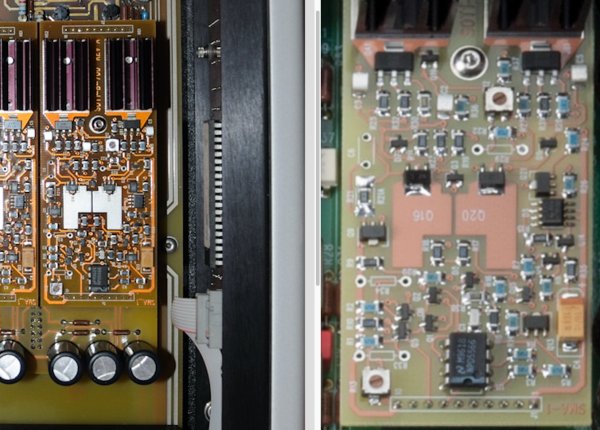

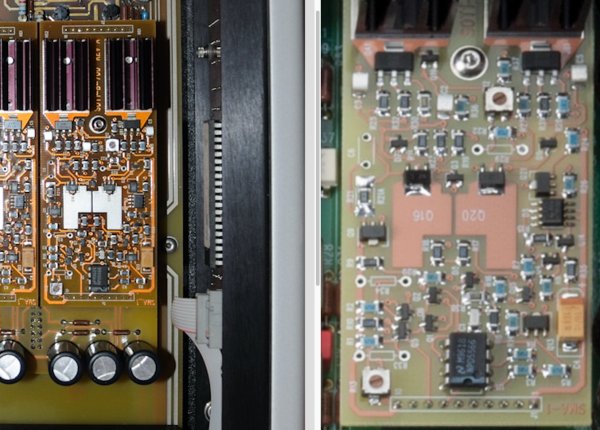

Maybe the new balanced input board. I'd be interested to see a hi-res picture of it.

I wish I had more time to elaborate but I'm leaving for my summer holidays so please don't think I'm being rude if I tend to summarize things.

SemiSouth going south is not irrelevant. You need to know the full story to understand what happened and the nature of semiconductor business. Interest in SiC devices started many years ago mostly because of their temperature performance. SiC works at higher temperatures than silicon. This is extremely valuable in military applications. Another valuable feature of SiC is their high frequency performance. Very good for things like switch mode power supplies and radar amplifiers. SemiSouth was a pioneer in that area when the market was focusing on those "high end" applications. I don't know whether they where founded by taxpayers or what, but in any case their business model did not succeeded in turning from a vertical market (MIL) to an horizontal market (CE). The Pass liaison was a tentative in exploring yet another niche before eventually folding down. The six digit sum that NP mentions is pocket change for a mainstream semiconductor company and not enough to keep alive a boutique company, so to speak. Mass adoption of SiC and eGaN is happening now, expect big things in the next two or three years. SiC will replace IGBTs in PFC power supplies. Do you remember Pass using IGBTs? (hint: Forte line, IGBTs where Toshibas actually made for audio, long gone and with a very short life on the market. Guess why?). Going back to SiC and new semis in general, companies like Cisco don't buy semiconductors that are not fully qualified for mass production, available from multiple sources and at the right price. Companies like Pass Labs and Spectral need exotic parts to differentiate from competitors. The SIT1 is a standard part from the SemiSouth line that was selected for parameters valuable for linear applications. It is NOT a custom part made to specs. Unless you are IBM or Intel, you don't develop new semiconductor processes or devices. You buy what is available. Customization is usually limited to package and parametric selection. This is true, in many cases, even for military. Most military programs use what is commonly available. Some strategic military programs can afford huge budgets and new devices. For instance, the Apollo program was the very first "mainstream" application of solid state devices, BJTs and logic gates packaged in IC style SMD packages. Think it through, this is the way new technologies evolve. Like I said, audio is a legacy industry and it uses whatever is left from mainstream applications. In the 70s parts similar to the SIT1 where developed by companies like Sony and Yamaha. Nowadays, no semiconductor company is willing to develop parts specifically made for audio. Not enough business. The only company that somewhat differ from this rule is probably That Corporation.

I'm somewhat disappointed by the latest "upgrade" to the SHHA because it seems to me that what actually happened is Spectral buying a six digit sum of NPD5566 before they disappeared (it is called Last Time Buy in the industry), used that stash until it was depleted and then replaced the part with its modern equivalent. Nothing wrong with this. It is common practice in manufacturing. But I'm still disappointed by the fact that a superior part, the 2SK389 and then the LSK389, has been available for such a long time before it actually made it to the SHHA. So, in the end, what is OK for manufacturing is not for R&D. If a new part can give you an edge, why not using it (in the boutique industry that high end audio is).

This is not to say that the adoption of a new part and the redesign of the circuit to take full advantage of it (elimination of thermal tails) is not relevant. I'm quite sure the DMC 30SV is a great piece of engineering. I was only expecting something more.

Maybe the new balanced input board. I'd be interested to see a hi-res picture of it.

Rude? On the contrary, this is fascinating discussion for me, as I am tired of those other threads about "science" in audio and such... THIS is more interesting to me, and I've always said that my purchasing priorities are designer-->design-->sound. So all of what you wrote is really welcome here...

To the point, you appear to be making a couple of key claims:

This implies that Pass is (was) rebadging a standard part, that perhaps he helped revive, but nonetheless, is not really custom

This asserts we are at the bottom of the food chain. Are we really?

On his First Watt URL and the 6moons article I cited, Pass makes plenty of references to the Sony and Yamaha devices (with pictures, in fact). The sticky part in all of this, then, is, what drove the manufacturing of this new "Pass-SIT-1" device? My interpretation of what you wrote and I quoted here is that, Pass may have simply convinced someone (SemiSouth) to re-build the Sony/Yamaha devices (probably because they are extremely rare, if at all available), and by perhaps using modern manufacturing techniques, you end up with a better device; and that is probably all there is to being "custom", if at all - that would really be more like "unique to me"/proprietary rather than custom, assuming Pass bought the entire batch; and if he didn't, then there is really nothing proprietary either. Am I reading this correctly?

The following sentence in Pass's First Watt link caught my attention: "The other is First Watt, which arranged for a production run of a new SIT device using a newer Silicon Carbide process by SemiSouth" - all that says to me now is that Pass simply convinced someone to build this new/old device, rather than making it truly "custom" to him, although we may be getting caught up in semantics; again, did he buy the entire batch or not; if he did, one can technically call it 'custom', though not groundbreaking from a design perspective, rather more like a modern-day copy.

So let's ask this: have you seen those SIT devices in other brands?

Interesting... you are saying Spectral could have used this superior part long ago, but because they allegedly stocked so much of the older part, it is only now that they have decided to use it. OK, so this begs the following question: what of the other claim of theirs I posted, "custom semiconductor technology developed for high-resolution display applications" - is there any possibility for those devices to be "custom" or even proprietary, and what devices are those for "high-resolution display applications"? In the 300RS video, if you go to 20:04, Fryer literally claims "custom JFets". Are they using the term "custom" a bit too freely???

I have to admit some things are not adding up...

And I'll get hi-rez pictures of the new balanced input board... Enjoy the vaca...

To the point, you appear to be making a couple of key claims:

The SIT1 is a standard part from the SemiSouth line that was selected for parameters valuable for linear applications. It is NOT a custom part made to specs.

This implies that Pass is (was) rebadging a standard part, that perhaps he helped revive, but nonetheless, is not really custom

audio is a legacy industry and it uses whatever is left from mainstream applications

This asserts we are at the bottom of the food chain. Are we really?

In the 70s parts similar to the SIT1 where developed by companies like Sony and Yamaha. Nowadays, no semiconductor company is willing to develop parts specifically made for audio. Not enough business.

On his First Watt URL and the 6moons article I cited, Pass makes plenty of references to the Sony and Yamaha devices (with pictures, in fact). The sticky part in all of this, then, is, what drove the manufacturing of this new "Pass-SIT-1" device? My interpretation of what you wrote and I quoted here is that, Pass may have simply convinced someone (SemiSouth) to re-build the Sony/Yamaha devices (probably because they are extremely rare, if at all available), and by perhaps using modern manufacturing techniques, you end up with a better device; and that is probably all there is to being "custom", if at all - that would really be more like "unique to me"/proprietary rather than custom, assuming Pass bought the entire batch; and if he didn't, then there is really nothing proprietary either. Am I reading this correctly?

The following sentence in Pass's First Watt link caught my attention: "The other is First Watt, which arranged for a production run of a new SIT device using a newer Silicon Carbide process by SemiSouth" - all that says to me now is that Pass simply convinced someone to build this new/old device, rather than making it truly "custom" to him, although we may be getting caught up in semantics; again, did he buy the entire batch or not; if he did, one can technically call it 'custom', though not groundbreaking from a design perspective, rather more like a modern-day copy.

So let's ask this: have you seen those SIT devices in other brands?

But I'm still disappointed by the fact that a superior part, the 2SK389 and then the LSK389, has been available for such a long time before it actually made it to the SHHA.

Interesting... you are saying Spectral could have used this superior part long ago, but because they allegedly stocked so much of the older part, it is only now that they have decided to use it. OK, so this begs the following question: what of the other claim of theirs I posted, "custom semiconductor technology developed for high-resolution display applications" - is there any possibility for those devices to be "custom" or even proprietary, and what devices are those for "high-resolution display applications"? In the 300RS video, if you go to 20:04, Fryer literally claims "custom JFets". Are they using the term "custom" a bit too freely???

I have to admit some things are not adding up...

And I'll get hi-rez pictures of the new balanced input board... Enjoy the vaca...

Spectral DMC-30SS S2 SN# Sound improvement

I have purchased my second DMC-30SS S2 with a higher SN# 30845 along with a DMA-260 S1.

Have not set up the 30SS S2 yet. Pending cables, Speakers and source.

I found the first 30SS S2 Upgraded from a S1 sound to have more resolution and lower coloration then the 30SL that it replaced but prefered the 30SL with all the coloration.

What are your thoughts.

It's better to buy the 30SV, soundwise. Cost factoring in, I can't make that argument... Keep in mind though that the reason I re-bought a new 30SS S2 last year, replacing an original S2 version, is that the sound was significantly better, almost an "S3" revision. Yet, there were no easily discernible board differences, and I was told "there may be changes that you can't see". The point being that there may be other changes in the 30SV beyond what's discussed in this thread or the bulletins. In other words, you should probably expect to get what you pay for.

I have purchased my second DMC-30SS S2 with a higher SN# 30845 along with a DMA-260 S1.

Have not set up the 30SS S2 yet. Pending cables, Speakers and source.

I found the first 30SS S2 Upgraded from a S1 sound to have more resolution and lower coloration then the 30SL that it replaced but prefered the 30SL with all the coloration.

What are your thoughts.

I have purchased my second DMC-30SS S2 with a higher SN# 30845 along with a DMA-260 S1.

Have not set up the 30SS S2 yet. Pending cables, Speakers and source.

I found the first 30SS S2 Upgraded from a S1 sound to have more resolution and lower coloration then the 30SL that it replaced but prefered the 30SL with all the coloration.

What are your thoughts.

You are probably the only one I know that likes the 30SL and its coloration. I went from the 30SL G2 to the 30SS S2, and the improvement was quite obvious, dramatic and welcome. Then the new S2 came in with more dynamics; the late serial # is definitely what you want (mine is in the 950+ range I think, and not sure if it's different that what you got)

ack,

I'd like to provide some answers to your questions and convey more information about semis. First off, you made a very good point about designer-design-sound priorities, I will elaborate on this later.

Going back to SemiSouth SITs, the fundamental theory goes back to the mid '70s and was developed by Dr. Jun-ichi Nishizawa in Japan. Devices developed in that era were made of Si (silicon). A SIT (static induction transistor) is actually a JFET on steroids, a normally-on power device. JFETs, the very few left, are typically small signal devices. SITs were made for high frequency power processing, back then like today. The BIG differences between legacy Sony and Yamaha devices and the new SemiSouth devices are material and mode of operation. SemiSouths are made of SiC (silicon carbide) to take advantage of the material characteristics: breakdown voltage and operating temperature are higher than is achievable with Si MOSFETs, FOM (figure of merit) for Rdson and Crss is also advantageous. This makes for a device that run faster at higher frequencies, voltages and temperature. SiC made possible another major breakthrough: a normally-off SIT. You need to apply voltage to the gate to turn on the device (current flows between drain and source). This is a huge advantage in power applications as it makes control circuitry much easier and intrinsically safe. But I digress, just wanted to point out that SIT1 is in no way a replacement for 2SK and 2SJ legacy devices. Those are long gone and only available as NOS (new old stock), until they last. There is another subtle but fundamental difference between the old Si parts and the SemiSouths. The marketplace. Back in the '70s audio WAS a mainstream market (for power devices) and companies like Sony and Yamaha could afford the expenses of developing devices optimized for linear operation. This is not going to happen in the new millennium. Sad but true. Even then, one of the target product for those devices was a switching Class D amplifier (Sony). It was just too ahead of its time to be a commercial success (today could be different with the mobile revolution). What happened was the Si MOSFET became a commercial success thanks to International Rectifier and the industry made his decision (remember the normally-on feature of SITs? Not good.). The rest is history. There is ONE family of lateral MOSFETs developed by Toshiba (now sold by Renesas, until they last) that where specifically developed for audio but, again, it is a few parts against literally thousands of parts made for switching applications.

So, are we really at the bottom of the food chain?

Yes and no!

Linear amplifiers, preamps, power amps? Yes. Do not expect anything new from the semi industry. Have you noticed that even the SemiSouths are only available as N channel? N and P complements like the old Sony and Yamaha SITs? A time machine to bring you back in the '80s is more probable than Toshiba, or maybe Samsung? making one of those today. Use what you have, there are plenty and they are good enough (not the best though). Period.

Digital, DSP and new software and interfaces will be the focus of the semi industry for the years to come. Audio will be much different for the better. Product differentiation will be on software rather than hardware. Think about it, why is my old iPhone 5 so much better than my daughter's Moto G? (Don't want to start a iOS / Android war here just compare the hardware specs of the two devices and their street prices).

just compare the hardware specs of the two devices and their street prices).

What I said is the key to understand why the designer-design-sound priority is so important. Nelson Pass and KOJ were there when all those great devices were available. And they were doing audio designs with them. The experience the made is invaluable if you are aiming for the best. Most of the tools available today are so much better. But who knows how to use those tools for audio design? How do you teach experience?

And, back to ack's questions, whether the SIT1 is actually a custom part or not is a matter of semantic. Take a standard part, laser mark it with your own P/N and it is no longer a standard part. This was done with the STASIS N and STASIS P power transistors for instance. Difference between the STASIS N and a Motorola MJ15xxx? The name. Issue an SCD (specification control drawing) and a standard part is tested to your specifications. Lower tolerances for instance, was this the case with either the STASIS parts or the SIT1? Possibly.

And, have I seen the SemiSouth SITs in other brands? No, SemiSouth went south before that could happen and, BTW, it would have happened only for boutique products. Remember the lack of complements, no P parts? Audio power amplifiers are usually push-pull. You need to be Nelson Pass to make a single ended solid state amplifier attractive on the marketplace. It's marketing. This is a fashion industry, well... mostly If have come this far you understand what I mean.

If have come this far you understand what I mean.

I don't have a good answer for the "custom semiconductor technology developed for high resolution display". I haven't seen the video yet. Will come back to this later. In any case, I remember Pioneer using high speed BJTs drivers in their best power amps. But those were the times when high resolution displays were cathode ray tubes. High speed, high voltage BJTs were ideal for that application. I'm talking about 25 years ago, maybe.

Enough for now. I'll go to see the video.

Have fun.

I'd like to provide some answers to your questions and convey more information about semis. First off, you made a very good point about designer-design-sound priorities, I will elaborate on this later.

Going back to SemiSouth SITs, the fundamental theory goes back to the mid '70s and was developed by Dr. Jun-ichi Nishizawa in Japan. Devices developed in that era were made of Si (silicon). A SIT (static induction transistor) is actually a JFET on steroids, a normally-on power device. JFETs, the very few left, are typically small signal devices. SITs were made for high frequency power processing, back then like today. The BIG differences between legacy Sony and Yamaha devices and the new SemiSouth devices are material and mode of operation. SemiSouths are made of SiC (silicon carbide) to take advantage of the material characteristics: breakdown voltage and operating temperature are higher than is achievable with Si MOSFETs, FOM (figure of merit) for Rdson and Crss is also advantageous. This makes for a device that run faster at higher frequencies, voltages and temperature. SiC made possible another major breakthrough: a normally-off SIT. You need to apply voltage to the gate to turn on the device (current flows between drain and source). This is a huge advantage in power applications as it makes control circuitry much easier and intrinsically safe. But I digress, just wanted to point out that SIT1 is in no way a replacement for 2SK and 2SJ legacy devices. Those are long gone and only available as NOS (new old stock), until they last. There is another subtle but fundamental difference between the old Si parts and the SemiSouths. The marketplace. Back in the '70s audio WAS a mainstream market (for power devices) and companies like Sony and Yamaha could afford the expenses of developing devices optimized for linear operation. This is not going to happen in the new millennium. Sad but true. Even then, one of the target product for those devices was a switching Class D amplifier (Sony). It was just too ahead of its time to be a commercial success (today could be different with the mobile revolution). What happened was the Si MOSFET became a commercial success thanks to International Rectifier and the industry made his decision (remember the normally-on feature of SITs? Not good.). The rest is history. There is ONE family of lateral MOSFETs developed by Toshiba (now sold by Renesas, until they last) that where specifically developed for audio but, again, it is a few parts against literally thousands of parts made for switching applications.

So, are we really at the bottom of the food chain?

Yes and no!

Linear amplifiers, preamps, power amps? Yes. Do not expect anything new from the semi industry. Have you noticed that even the SemiSouths are only available as N channel? N and P complements like the old Sony and Yamaha SITs? A time machine to bring you back in the '80s is more probable than Toshiba, or maybe Samsung? making one of those today. Use what you have, there are plenty and they are good enough (not the best though). Period.

Digital, DSP and new software and interfaces will be the focus of the semi industry for the years to come. Audio will be much different for the better. Product differentiation will be on software rather than hardware. Think about it, why is my old iPhone 5 so much better than my daughter's Moto G? (Don't want to start a iOS / Android war here

What I said is the key to understand why the designer-design-sound priority is so important. Nelson Pass and KOJ were there when all those great devices were available. And they were doing audio designs with them. The experience the made is invaluable if you are aiming for the best. Most of the tools available today are so much better. But who knows how to use those tools for audio design? How do you teach experience?

And, back to ack's questions, whether the SIT1 is actually a custom part or not is a matter of semantic. Take a standard part, laser mark it with your own P/N and it is no longer a standard part. This was done with the STASIS N and STASIS P power transistors for instance. Difference between the STASIS N and a Motorola MJ15xxx? The name. Issue an SCD (specification control drawing) and a standard part is tested to your specifications. Lower tolerances for instance, was this the case with either the STASIS parts or the SIT1? Possibly.

And, have I seen the SemiSouth SITs in other brands? No, SemiSouth went south before that could happen and, BTW, it would have happened only for boutique products. Remember the lack of complements, no P parts? Audio power amplifiers are usually push-pull. You need to be Nelson Pass to make a single ended solid state amplifier attractive on the marketplace. It's marketing. This is a fashion industry, well... mostly

I don't have a good answer for the "custom semiconductor technology developed for high resolution display". I haven't seen the video yet. Will come back to this later. In any case, I remember Pioneer using high speed BJTs drivers in their best power amps. But those were the times when high resolution displays were cathode ray tubes. High speed, high voltage BJTs were ideal for that application. I'm talking about 25 years ago, maybe.

Enough for now. I'll go to see the video.

Have fun.

Seen the video.

Well, it was a marketing presentation after all. Not a tech conference.

I tend to be skeptical about most of the info about semis. You can be personal friend with the CEO of Fairchild but having custom made dies because of that is simply not going to happen. Not for a limited production factory anyway. Even custom packages would be out of reach for small quantities, not to mention custom dies.

To put things into perspective, in the mid '90s I was working with a power supply company that used to have a clean room for custom semiconductor packaging. We were buying wafers from the big guys and diced them into dies, in-house. It was unique in the industry back then. The company invested tens of M$ to make it happen. We were processing tens of thousand of MOSFETs per month. We were a high potential customer for companies like IRF, Fairchild, etc. Very well respected.

I've met an IRF engineer at a trade show and he was a good friend of my boss so we had a very open conversation about the business trends etc. Our largest customer in Italy was also their largest customer.

I asked this engineer whether IRF was still selling bare dies, the only type of semis we were buying, and I felt his pain when he kindly declined the opportunity to do business with us. He explained that IRF was not willing to do business on bare dies because of the amount of troubles that comes with it. Not even with our common top customer, which was routinely using bare dies from a multitude of vendors. Reason: they are too small, not worth the effort. That company was the largest Italian electronics manufacturer with a turnover in the B$. Go figure.

I can imagine it may be different in the domestic (US) market, but not that much.

For a good perspective on the costs associated with semiconductor factories see:

http://www.infoworld.com/article/26...r-industry-looks-ahead-to-18-inch-wafers.html

Regards

Well, it was a marketing presentation after all. Not a tech conference.

I tend to be skeptical about most of the info about semis. You can be personal friend with the CEO of Fairchild but having custom made dies because of that is simply not going to happen. Not for a limited production factory anyway. Even custom packages would be out of reach for small quantities, not to mention custom dies.

To put things into perspective, in the mid '90s I was working with a power supply company that used to have a clean room for custom semiconductor packaging. We were buying wafers from the big guys and diced them into dies, in-house. It was unique in the industry back then. The company invested tens of M$ to make it happen. We were processing tens of thousand of MOSFETs per month. We were a high potential customer for companies like IRF, Fairchild, etc. Very well respected.

I've met an IRF engineer at a trade show and he was a good friend of my boss so we had a very open conversation about the business trends etc. Our largest customer in Italy was also their largest customer.

I asked this engineer whether IRF was still selling bare dies, the only type of semis we were buying, and I felt his pain when he kindly declined the opportunity to do business with us. He explained that IRF was not willing to do business on bare dies because of the amount of troubles that comes with it. Not even with our common top customer, which was routinely using bare dies from a multitude of vendors. Reason: they are too small, not worth the effort. That company was the largest Italian electronics manufacturer with a turnover in the B$. Go figure.

I can imagine it may be different in the domestic (US) market, but not that much.

For a good perspective on the costs associated with semiconductor factories see:

http://www.infoworld.com/article/26...r-industry-looks-ahead-to-18-inch-wafers.html

Regards

I've been waiting for a video like the following to appear, to respond to your last post - which is very thoughtful, as any other so far. It's a long video, but at the core of it, it seems like Fryer is responding to this thread and specifically whether devices are custom made or not. He is presenting the 30SV at Audio Graffiti in Italy - an event that took place this week, I believe - and I will point out just a couple of things:

Here's the video

- Early on, he says something like "if we can convince folks that these devices are custom fine, if we can't we can't"

- The real meat on the preamp starts around 18:30

- Scroll forward to 23:00, where he makes the following claim about those transistors in the SHHA3 module we've been talking about: "they are not made by machines they are made by people, people that are selecting the die"... that seems to be in direct response to your comments about dies... Then he goes on to claim "they are made in very small numbers". That would be an awful lot of lies by Fryer... I have no opinion of my own on this.

Here's the video

Hi,

I went through the video and I think Mr. Fryer misrepresents the current state of the art of discrete dual j-FETs, which is what I'm debating here.

Some facts:

Spectral goes to the expenses of developing a custom dual J-FET, in the sense of a breakthrough new semiconductor design, as intended by Mr. Fryer.

Questions:

Keep in mind that the two largest (which also means highest quality) manufacturers for dual J-FETs were Siliconix in the US and Toshiba in Japan. Siliconix is now Vishay and almost all the discrete J-FETs are gone. Toshiba did the same with almost all the PTH products. And, in any case, new, high quality parts, in the sense that Mr. Fryer implicitly intends, are only coming in SMT. Nobody, repeat: nobody, today builds electronics using PTH unless strictly necessary (isolation, component weight, etc.).

That said, there is a small industry within the semiconductor industry that specializes in obsolete part replacements and, of course, custom parts. Like I said, it could be something as simple as re-labeling up to custom-diffused parts. Look for companies like Interfet, Linear Integrated Systems, Calogic, Central Semiconductor, etc. This is the source of the exotic dual J-FET Mr. Fryer is talking about. Is this a custom? Maybe. Is it what Mr. Fryer want us to believe?

I think the answer is in Mr. Fryer's word starting at 13.45 in the video. Just replace the word "tubes" with "discrete J-FET".

And, like I said before, it doesn't detract from the quality of Spectral products which I truly believe is top notch.

I went through the video and I think Mr. Fryer misrepresents the current state of the art of discrete dual j-FETs, which is what I'm debating here.

Some facts:

- The NPD5566 was first designed-in into a Spectral product by Demian Martin in the early 80s. I have a DMC10 rev. 2 schematic dated 1981 that proves this.

- The NPD5566 was listed in National Semiconductor data book dated 1996 and soon discontinued thereafter. I don't know the exact date but I doubt it saw the dawn of the new millennium.

- Mr. Fryer says that the DMC30 was first introduced in 1999. The NPD5566 was probably EOL by the time the DMC30 was released.

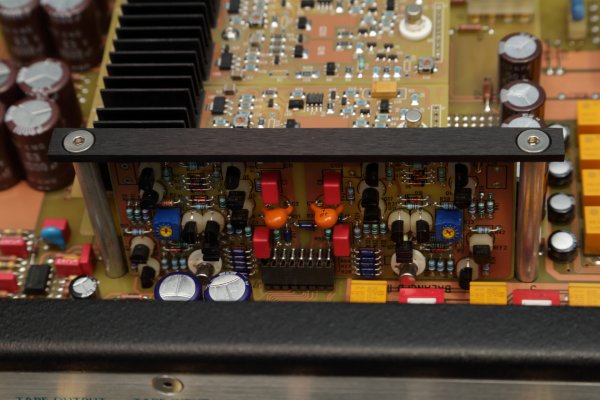

- Early versions (DMC30 SL) of the SHHA module have the SMA-1 identifier etched on the PCB. The SV version still uses the same SMA-1 PCB artwork.

Spectral goes to the expenses of developing a custom dual J-FET, in the sense of a breakthrough new semiconductor design, as intended by Mr. Fryer.

Questions:

- If you don't want to re-design the PCB artwork, why don't you ask for your new device to come in the same DIP8 package as the old one? Being a custom it can be packaged in any standard package. Why picking up an incompatible one? (Notice the TWO transistor spacers in the SV SHHA module to fit a TO71 into a DIP8 socket).

- You've spent a small fortune to get your fancy silicon. Why don't you go a little bit further and update the PCB to a modern SMD footprint? Miniaturization is what makes HF (read high speed) designs possible. Electrons travel at finite speed and distance means delay. The smaller the package the better the behavior at HF. After all, replacing a DIP8 with an SOIC8 on a PCB is a matter of minutes with a modern CAD and few tens of $ and a couple of days lead time to make it into production. Unless you have a stash of old boards to push out of the door.

- A "custom" is replacing a long discontinued device. Is this done to advance the "state of the art" or to give the product few more years of lifetime?

Keep in mind that the two largest (which also means highest quality) manufacturers for dual J-FETs were Siliconix in the US and Toshiba in Japan. Siliconix is now Vishay and almost all the discrete J-FETs are gone. Toshiba did the same with almost all the PTH products. And, in any case, new, high quality parts, in the sense that Mr. Fryer implicitly intends, are only coming in SMT. Nobody, repeat: nobody, today builds electronics using PTH unless strictly necessary (isolation, component weight, etc.).

That said, there is a small industry within the semiconductor industry that specializes in obsolete part replacements and, of course, custom parts. Like I said, it could be something as simple as re-labeling up to custom-diffused parts. Look for companies like Interfet, Linear Integrated Systems, Calogic, Central Semiconductor, etc. This is the source of the exotic dual J-FET Mr. Fryer is talking about. Is this a custom? Maybe. Is it what Mr. Fryer want us to believe?

I think the answer is in Mr. Fryer's word starting at 13.45 in the video. Just replace the word "tubes" with "discrete J-FET".

And, like I said before, it doesn't detract from the quality of Spectral products which I truly believe is top notch.

Hi geppo,

I couldn't possibly respond to any of your finer points, but perhaps I can raise some questions:

-ack

I couldn't possibly respond to any of your finer points, but perhaps I can raise some questions:

- "The NPD5566 was probably EOL by the time the DMC30 was released" - is this really a problem? Case in point those SITs that Pass resurrected, or the fact the original Toshiba were/are highly regarded???

- - "Early versions (DMC30 SL) of the SHHA module have the SMA-1 identifier etched on the PCB. The SV version still uses the same SMA-1 PCB artwork" - I am not sure exactly what you are looking at, some markings on the board? I am willing to bet it was modified and optimized in the SV, w/o new "versioning" markings on it

- - "Why don't you go a little bit further and update the PCB to a modern SMD footprint?" - How much does one stand to gain by going super small? And is SMD the only way to go high-performance?

- - "Miniaturization is what makes HF (read high speed) designs possible. Electrons travel at finite speed and distance means delay" - Spectrals are already very high speed, not to mention the SV sounds even higher-speed than any before; so how much faster does one need to go? And what does electron travel have to do with it, given that they travel extremely slowly at a snail's pace, thus signal-transmission has nothing to do with their motility?

- - "This is the source of the exotic dual J-FET Mr. Fryer is talking about. Is this a custom? Maybe" - I personally couldn't possibly know what the source might be, but I am glad you said "Maybe"; I find it hard to believe that someone would have the guts to a) post on their website untrue information; and b) tell customers face to face the same, especially a company which has established itself as one with exceptional engineering prowess...

- - Final question: what happens in the military/aerospace industries wrt custom devices? I understand it's a much bigger market, but don't forget that Spectral have partnered before - with "a leading aerospace contractor", as they claim in the 30SS bulletin - to come up with that custom Fader volume control (that you see in the pictures upthread), and in small quantities... Could they have formed a similar partnership this time again?

-ack

And a bit of news on the semiconductor industry... OnSemi is buying Fairchild http://www.reuters.com/article/2015/11/18/us-fairchild-semico-m-a-idUSKCN0T71HH20151118?feedType=nl

Last edited:

Hi ack,

Thanks for the great pictures. Spectral layout is a work of art and a pleasure to look at.

I had a look at the many pictures of the SHHA module I've saved over the years and this is what I've found:

Differences between the earliest version and one of the latest are minimal, to say the least:

Some parts seems to be upgraded going from REV A to REV D:

Interesting to note that the latest and greatest SV release has a new PCB artwork. This can be seen on just a couple of tracks running from resistors to the new TO71 dual J-FET that replaced the old NPD5566. Now that I've seen the new balanced board it makes sense to me. Spectral wanted to use the same J-FET for both a SMT and a THT board and installing a THT part in an SMD board is easier than the opposite. So, if only one part needs to be used it has to be THT.

That said, and to answer your well taken points:

I hope I correctly explained why, in my experience, I tend to be skeptical when I hear of breakthrough new semis specifically designed for audio, packaged in THT packages.

Regarding the Fairchild acquisition, I would recommend to read the wikipedia page for that company. You will realize that the company Mr. Fryer is talking about is long gone, long before the last name change.

Regards

Thanks for the great pictures. Spectral layout is a work of art and a pleasure to look at.

I had a look at the many pictures of the SHHA module I've saved over the years and this is what I've found:

- The SMA-1 marking has nothing to do with revision levels. The P/N along with REV is actually marked between the two heatsinks and it is SOT1-B-700 REV x.

- I've compared REV A - the first release I suppose - with REV D as published on Spectral website on the SDR-4000SL page. See:

Differences between the earliest version and one of the latest are minimal, to say the least:

- Same PCB artwork, at least for the top layer

- Same component placement, type, number and orientation

- All components are SMT with the exception of R33 and R34 in the input stage and C6 and R29 in the VAS / output stage

- THT components are not populated and probably used to fine tune parameters (offset, gain, compensation?)

Some parts seems to be upgraded going from REV A to REV D:

- PCB material

- Several resistors are thin film technology in the latest incarnation of the module while they were thick film in earlier version. Thin film is much better than thick film, objectively.

Interesting to note that the latest and greatest SV release has a new PCB artwork. This can be seen on just a couple of tracks running from resistors to the new TO71 dual J-FET that replaced the old NPD5566. Now that I've seen the new balanced board it makes sense to me. Spectral wanted to use the same J-FET for both a SMT and a THT board and installing a THT part in an SMD board is easier than the opposite. So, if only one part needs to be used it has to be THT.

That said, and to answer your well taken points:

- An old joke among engineers: "a project is not finished until it has at least an obsolete part and a still to be released part in its BOM". EOL parts are a major headache in the electronic industry. High End Audio is probably different and more tolerant. Not a good practice though.

- No big differences but sometimes the devil is in the details.

- SMD in audio preamps is actually not a necessity. Tube equipments prove the point. However, if you are striving for the highest speed, fastest settling time, SMD is the only way to achieve the objective. It has been since the last three decades, at least.

- I should have said "electricity" - in the sense of "signals" - rather than "electrons". In this context, Spectral preamps are exceedingly fast. Too fast, probably. What really matters is settling time, not pure bandwidth. This is a well understood principle in integrated circuit design. Much more difficult to achieve with discretes. Every stray, parasitic component tends to resonate at high frequencies (several hundreds of KHz, not necessarily MHz). The larger the component the larger its parasitic parameters. That simple.

- Like I said, it may be custom but it surely isn't a breakthrough new kind of dual J-FET. Discrete J-FETs are legacy technology like tubes. Minor refinements may be possible but, in most cases, small companies are striving to replicate, not exceed, the quality of old Toshiba and Siliconix parts.

- Military / aerospace is a different matter. They can afford any cost because they spend taxpayer's money. Their program are well funded and do not need to meet with market acceptance and quarterly revenue meetings. Obsolescence is a BIG issue. Weapons systems are long lifetime items. Look at it this way. In the cold war era nuclear weapons were tested "in the field", not simulated in a supercomputer. Once a design was qualified nothing shall be changed. You can't replace a qualified component without re-testing the system. A 30$ transistor is qualified with 30M$ of tests, for instance. The usual solution to the obsolescence dilemma is either a "lifetime buy" - buy as many part as you need for the life of your project, including spares - or by transferring the manufacturing capabilities of original manufacturers to small, specialized companies. Those companies are specializing in replacing an existing part with an equivalent part. Major improvements are simply not requested and surely not welcome.

I hope I correctly explained why, in my experience, I tend to be skeptical when I hear of breakthrough new semis specifically designed for audio, packaged in THT packages.

Regarding the Fairchild acquisition, I would recommend to read the wikipedia page for that company. You will realize that the company Mr. Fryer is talking about is long gone, long before the last name change.

Regards

Similar threads

- Replies

- 36

- Views

- 2K

- Replies

- 34

- Views

- 2K

- Replies

- 12

- Views

- 2K

- Replies

- 15

- Views

- 711

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Co-Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |